Description

The GE IS210BPPCH1AC tackles a key pain point in industrial automation and turbine control systems: delivering dependable, high-performance local processing for I/O packs in demanding, real-time environments where legacy or underpowered processors risk latency, reduced diagnostic depth, or compatibility gaps during upgrades. In gas and steam turbine applications—particularly within GE’s Speedtronic Mark VIe platforms—operators and engineers frequently face challenges with I/O pack reliability under vibration, temperature extremes, and electromagnetic interference common in power generation facilities. Without a robust processor daughterboard, I/O packs can struggle to handle fast scan rates, execute complex local logic, or provide granular fault reporting, leading to slower fault isolation, increased nuisance alarms, or even forced outages in critical assets.

GE IS210BPPCH1AC emerges as the internal UCPA (Universal Control Pack Assembly) processor solution engineered to overcome these limitations. It equips I/O packs with enhanced embedded processing power, enabling them to manage local data acquisition, preliminary signal conditioning, and communication with the central controller more efficiently. This becomes essential in setups requiring high reliability for I/O signals tied to turbine protection, sequencing, and governor control—situations where milliseconds matter for overspeed detection, flame detection, or load rejection events. By upgrading from older BPPB-series packs, GE IS210BPPCH1AC supports modern firmware demands and diagnostic features, helping teams maintain process control stability without wholesale system replacement. For engineers assessing retrofits or expansions, this board minimizes integration risks in distributed control architectures, ensuring consistent performance in harsh industrial environments while preserving investment in existing Mark VIe infrastructure.

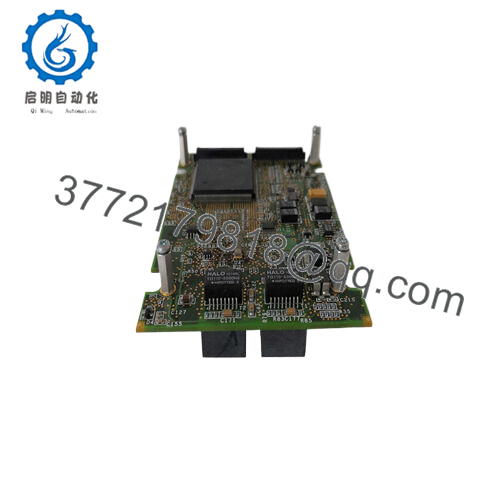

The GE IS210BPPCH1AC serves as the core processor daughterboard within GE’s Mark VIe Speedtronic I/O packs, specifically designed for the UCPA configuration. It mounts directly onto compatible I/O terminal boards or base modules, handling the local intelligence for analog, digital, and specialized I/O types. Powered nominally at 12 V DC (operating range 9–16 V DC), it draws from the pack’s internal supplies to run its embedded processor, manage serial interfaces, and coordinate data exchange over the system’s IONet or other high-speed links to the Mark VIe controller.

Positioned in the distributed I/O layer of the Mark VIe stack, GE IS210BPPCH1AC processes raw field signals close to the source—reducing wiring-induced noise and latency—before packaging timestamped, validated data for upstream transmission. It supports diagnostic capabilities including local CPU health monitoring, power supply supervision, and status LEDs (typically red/green for fault/run indications), feeding detailed health data back to ToolboxST for configuration, trending, and alarm management. The board enables flexible system topologies: simplex for cost-sensitive applications, dual for availability, or TMR (triple modular redundancy) for highest-integrity protection loops.

In practice, GE IS210BPPCH1AC interacts seamlessly with various I/O packs (e.g., those handling thermocouples, speed sensors, or discrete actuators), executing local algorithms for filtering, voting, or limit checking to offload the main controller. This distributed intelligence is key in large turbine fleets, allowing independent pack operation during network glitches while maintaining synchronization under normal conditions. Compatible with ControlST software suite, it simplifies commissioning and online monitoring without disrupting operations. Overall, GE IS210BPPCH1AC anchors reliable I/O performance in the Mark VIe architecture, bridging field devices to turbine control logic with the speed and robustness needed for continuous, mission-critical service.

- IS210BPPCH1AC

| Specification | Details |

|---|---|

| Model Number | IS210BPPCH1AC |

| Brand | GE (General Electric) / GE Boards & Turbine Control |

| Type | I/O Pack Processor Daughterboard (UCPA Internal Processor) |

| Input Voltage | 9 to 16 V DC (nominal 12 V DC) |

| Operating Temp Range | Typically 0 to +60 °C (Mark VIe standard; confirm with system enclosure) |

| Mounting Style | Daughterboard mounted on UCPA I/O pack base/terminal board |

| Dimensions | Approx. 138 mm width × 86 mm depth × 56 mm height (board-level) |

| Weight | Approx. 0.2–0.3 kg |

| Interface/Bus | Internal to I/O pack; serial interfaces; IONet compatible upstream |

| Compliance | CE, UL, designed for industrial/hazardous locations per Mark VIe certs |

| Supported Protocols | Mark VIe IONet, internal pack diagnostics; ToolboxST integration |

| Typical Power Draw | Low (embedded processor; exact draw depends on I/O pack configuration) |

Selecting GE IS210BPPCH1AC yields tangible improvements in system responsiveness and maintainability. Engineered for high reliability in turbine control and industrial automation, it provides the processing headroom to handle demanding scan cycles and local diagnostics, reducing the likelihood of undetected faults that could escalate into trips or efficiency losses. The board’s upgrade path from prior generations ensures smoother transitions during modernization, with better component longevity and support for contemporary firmware—contributing to extended mean time between failures in 24/7 power generation assets.

In operational terms, GE IS210BPPCH1AC simplifies troubleshooting through clear status indicators and detailed ToolboxST visibility, allowing technicians to pinpoint issues at the pack level rather than tracing back to the controller. This cuts diagnostic time during startups or after events, while the board’s robust design withstands electrical noise and thermal cycling common in plant environments. By enabling distributed intelligence, it also lowers controller loading, freeing resources for advanced functions like model-based control or predictive analytics—ultimately supporting higher availability and optimized turbine performance with reduced engineering overhead.

GE IS210BPPCH1AC finds widespread deployment in gas and steam turbine control systems within power plants, including combined-cycle facilities, peaking units, and industrial cogeneration sites where critical system uptime is non-negotiable. It’s commonly used in Mark VIe-equipped heavy-duty turbines for processing inputs from speed probes, vibration sensors, and flame detectors, ensuring precise overspeed protection and synchronization under variable load conditions. In oil & gas applications, such as compressor drives or mechanical drive turbines, GE IS210BPPCH1AC supports fast-response sequencing in harsh offshore or refinery settings with high EMI and vibration.

The board excels in environments requiring high reliability I/O signals for continuous operation, like base-load plants needing millisecond-level event capture for post-trip analysis or regulatory reporting. Renewable integration projects pairing turbines with grid support also leverage it for stable governor response in fluctuating conditions. Across these scenarios, GE IS210BPPCH1AC upholds process control integrity in industrial automation stacks focused on efficiency, emissions compliance, and minimal forced outages.

Here are some related or compatible products in the GE Mark VIe Speedtronic family:

IS210BPPCH1ACA – Later revision of the BPPC processor with potential component updates for enhanced longevity.

IS210BPPCH1AD – Variant offering slight differences in processing or compatibility for specific I/O pack configurations.

IS210BPPCH1AEC – Another evolution in the BPPC series, often seen in upgraded packs with newer hardware.

IS215WEPAH2BB – Multiport interface board that frequently pairs with IS210BPPCH1AC as the processor daughterboard.

IS215AEPCH1FA – Control/processor assembly incorporating IS210BPPCH1AC for expanded I/O handling.

IS200AEPAH1BHC – Related multiport interface board using IS210BPPCH1AC in certain assemblies.

IS420UCSBH4A – Modern Mark VIe controller that interfaces with I/O packs featuring this processor type.

IS200ERIOH1ABB – Remote I/O module compatible within the same Mark VIe distributed architecture.

Before installing GE IS210BPPCH1AC, confirm exact compatibility with your UCPA I/O pack base (e.g., matching revision codes and firmware) and verify the Mark VIe controller supports the board’s feature set via ToolboxST. Ensure the 12 V DC supply is stable within 9–16 V range, with proper grounding to avoid noise issues. Check enclosure ventilation against temperature limits and inspect mating connectors for cleanliness or pin damage—mismatches here can prevent proper seating or cause intermittent faults. Update pack firmware if needed to align with current system revisions.

For ongoing maintenance, routinely observe status LEDs during patrols: green for normal, red for faults prompting immediate diagnostics via ToolboxST. Periodically review pack health logs for early warnings on processor or power anomalies. Clean dust from vents and connectors annually, especially in dusty or corrosive areas, and test I/O functionality during planned outages to validate signal paths and timing. In redundant setups, monitor sync status and exercise pack isolation tests as part of reliability programs. With its solid-state design, GE IS210BPPCH1AC requires little routine adjustment, but proactive checks keep it contributing to long-term turbine availability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626