Description

GE IS215UCVEH2AF is deployed in power plants and critical process facilities that rely on GE Mark VI turbine control to keep gas, steam, or combined‑cycle units running safely and efficiently. In these environments, it functions as the main computing engine on a VME controller rack, executing control algorithms that manage fuel flow, steam valves, inlet guide vanes, and auxiliaries such as lube‑oil and seal‑oil systems. Operators depend on GE IS215UCVEH2AF to coordinate fast sequencing, protective trips, and continuous monitoring of vibration, temperatures, pressures, and speeds, often under demanding grid and load‑change conditions. Because outages on these units are extremely costly, the board is usually installed in redundant Mark VI architectures, so a backup controller can take over if the primary fails.

Beyond power generation, GE IS215UCVEH2AF is used in large rotating‑equipment trains in oil and gas, petrochemical, and industrial cogeneration plants where Mark VI has been specified as the standard turbine and compressor control platform. In these cases, it sits at the heart of the control system, linking field termination and I/O boards on the VME backplane with plant networks via Ethernet and serial ports. The board’s ability to run complex application software, interface with operator HMIs, and communicate with DCS or PLC networks makes it central to both real‑time control and higher‑level asset management. In short, GE IS215UCVEH2AF is used in industrial automation wherever a high‑reliability Mark VI controller is needed to govern critical turbomachinery and associated balance‑of‑plant systems.

Product introduction and positioning

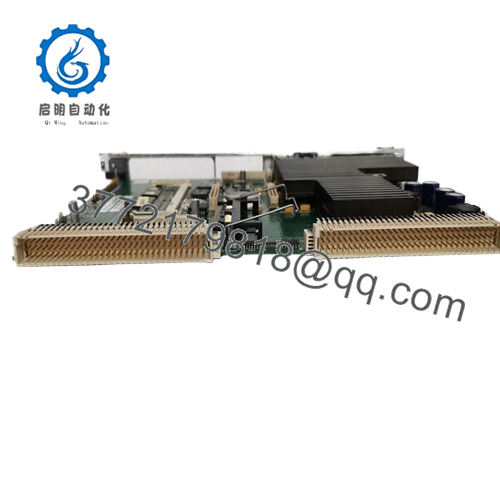

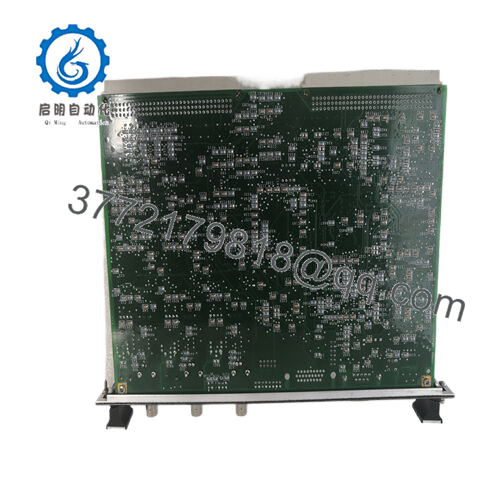

The GE IS215UCVEH2AF is a VME‑based controller board designed for the GE Mark VI turbine control system, acting as a high‑performance central processing unit for a single‑slot position in the VME rack. It combines an Intel Celeron 300 MHz processor with local memory, non‑volatile storage, and communication interfaces to execute turbine and process control applications. Within a Mark VI panel, this board runs the core control firmware and user‑configured logic that handle sequencing, protection, and closed‑loop regulation, while other VME and terminal boards concentrate the field wiring and conditioning

In the overall control‑system architecture, GE IS215UCVEH2AF occupies the controller layer between front‑end I/O modules and plant‑wide supervisory systems such as DCS, SCADA, or plant historians. It communicates with Mark VI I/O boards across the VMEbus, collecting real‑time input data and issuing output commands, and it exposes data and diagnostics upstream via Ethernet and serial links to operator stations and higher‑level control. Engineers value this board because it allows Mark VI systems to implement sophisticated logic and advanced diagnostics while preserving the robust, field‑proven VME hardware platform. As a result, GE IS215UCVEH2AF is positioned as a key controller option for Mark VI installations that require high reliability, modular expansion, and long‑term availability of spares.

Key technical features and functional benefits

A core strength of GE IS215UCVEH2AF is its Intel Celeron 300 MHz processor combined with 32 MB of DRAM and a 128 KB L2 cache, which together provide sufficient computing power for demanding turbine‑control algorithms and extensive diagnostics. This processing capability enables fast execution of protection logic, complex sequencing, and multiple closed‑loop control tasks without compromising scan times. Applications benefit from the board’s ability to handle large configuration databases and event logging, which are critical when assessing plant upsets or tuning control performance in high‑value assets.

The memory architecture of GE IS215UCVEH2AF includes flexible CompactFlash storage options—typically 16 MB or 128 MB—as well as 8 KB of battery‑backed SRAM used as non‑volatile memory for key controller data. This combination allows the system to retain essential parameters, configuration, and logs across power interruptions while still providing removable media for firmware and application updates. For operators, that means configuration integrity and easier field service: a technician can replace or update CompactFlash as part of maintenance while preserving critical NVRAM‑based data that the controller needs for safe restart.

In terms of connectivity, GE IS215UCVEH2AF offers at least one 10BaseT/100BaseTX Ethernet port and dual serial communication ports (often COM1 and COM2 using micro‑miniature 9‑pin D‑connectors). This supports integration with turbine HMIs, plant networks, and service laptops, as well as legacy serial links to external devices. The Ethernet interface enables fast data exchange with Mark VI operator stations and higher‑level systems, while serial ports can connect to modems, local diagnostic tools, or specific field devices. This multi‑protocol flexibility is valuable during upgrades, where both modern Ethernet‑based and legacy serial instruments may coexist.

The VME hardware design of GE IS215UCVEH2AF is compact—approximately 8.6 cm wide by 16.2 cm high—yet rugged enough for installation in turbine control panels where vibration and temperature variations are expected. The specified operating range from about −30 °C to +65 °C helps the board withstand harsh equipment room conditions and supports outdoor or minimally conditioned enclosures when properly engineered. Combined with Mark VI’s support for redundant controller configurations, this hardware robustness contributes to high availability and low risk of controller‑related trips in critical power‑generation service.

- IS215UCVEH2AF

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | GE IS215UCVEH2AF |

| Brand | General Electric |

| Product type | VME controller board / CPU module for Mark VI system |

| System platform | GE Mark VI turbine control system |

| Processor | Intel Celeron, 300 MHz clock frequency |

| DRAM memory | 32 megabytes |

| L2 cache | 128 kilobytes |

| CompactFlash options | 16 MB or 128 MB CompactFlash module |

| NVRAM | 8 KB battery‑backed SRAM |

| Ethernet interface | 10BaseT/100BaseTX Ethernet port |

| Serial interfaces | Two COM ports via micro‑miniature 9‑pin D connectors |

| Operating temperature | Approximately −30 °C to +65 °C |

| Physical size | About 8.6 cm wide × 16.2 cm high |

| Mounting | Single‑slot VME (Versa Module Eurocard) board |

Related modules or compatible units

IS215UCVEM01A – Alternative or related Mark VI controller board sharing similar VME form factor, often used in turbine control systems alongside or as a variant of GE IS215UCVEH2AF

IS200STCIH1A – Mark VI terminal board providing contact input interfacing; typically connects field contacts to the VME controllers such as GE IS215UCVEH2AF.

IS200STAIH2A – Analog input terminal board used with Mark VI to route process signals into the control system that is supervised by GE IS215UCVEH2AF.

IS200SPROH2A – Protection‑related terminal or interface board used in turbine overspeed and protection schemes managed by controllers like GE IS215UCVEH2AF.

IS200DWLAH1A – Mark VI communication or network interface component that helps integrate GE IS215UCVEH2AF‑based controllers into plant‑wide networks.

IS200BICLH1A – Backplane or bus‑interface module associated with VME racks that host GE IS215UCVEH2AF, ensuring proper communication on the Mark VI bus.

GE Mark VIe controllers (e.g., IS220 series) – Newer platform controllers considered upgrade paths for systems originally built around GE IS215UCVEH2AF, offering enhanced diagnostics and networking.

Installation notes and maintenance best practices

When installing GE IS215UCVEH2AF, engineers should ensure the Mark VI VME rack has the correct slot assignment, backplane connections, and power capacity for the controller board. Proper electrostatic discharge handling is essential during insertion and removal to protect sensitive components. The board must be fully seated in the VME connector, and any retaining hardware properly secured to withstand vibration typical of turbine halls. Field wiring does not land directly on the board but on associated terminal boards; however, Ethernet and serial cables should be routed to maintain separation from high‑voltage or high‑current wiring and should be strain‑relieved to avoid mechanical stress on the connectors.

For maintenance, GE IS215UCVEH2AF should be included in scheduled inspections of Mark VI panels. Technicians should verify that the controller remains firmly seated, that LEDs and status indicators show healthy operation, and that there are no signs of overheating or contamination. CompactFlash modules and batteries associated with NVRAM retention should be replaced according to site procedures and manufacturer recommendations to avoid unexpected data loss. Periodic backups of controller configuration, application software, and event logs are important so a replacement GE IS215UCVEH2AF can be commissioned quickly in case of failure. Monitoring board temperatures, communication statistics, and diagnostic alerts through the Mark VI tools helps detect emerging issues early and supports condition‑based maintenance strategies.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626