Description

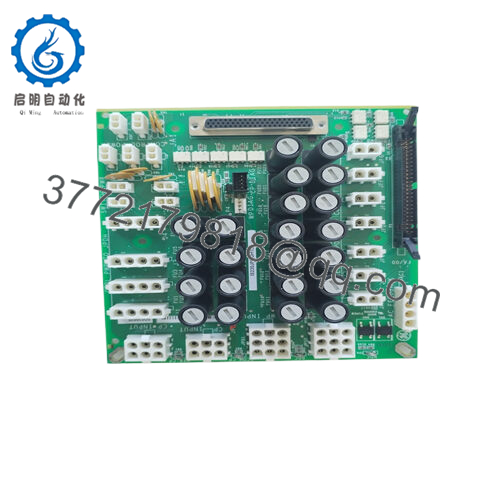

The GE IS230SNCIH6A solves a persistent challenge in industrial automation and turbine control systems: reliably acquiring discrete signals from field devices in distributed, high-availability architectures where standard I/O modules may fall short on voltage handling, environmental ruggedness, or diagnostic depth. In GE Mark VIe and Mark VIeS-based setups—common in gas and steam turbines for power generation, mechanical drives, or combined-cycle plants—engineers often deal with noisy or higher-voltage discrete inputs (e.g., from relays, switches, or interlocks operating at elevated DC levels) that demand robust isolation, fault detection, and seamless integration into redundant or safety-critical loops. Without a module capable of higher input ratings and advanced on-board supervision, signal integrity suffers, leading to false detections, delayed fault isolation, or compliance hurdles in protection and sequencing functions.

GE IS230SNCIH6A provides a purpose-built discrete input solution as part of the Mark VIe distributed I/O family. It handles 125 V DC nominal inputs (with appropriate range tolerance) across multiple channels, delivering high reliability for I/O signals in demanding applications like breaker status monitoring, emergency trip circuits, or permissive interlocking where lower-voltage modules risk saturation or inadequate suppression. This becomes critical during high-stakes operations—startup permissives, load rejection, or overspeed protection—where a single unreliable input could trigger unnecessary trips or compromise safety. Featuring conformal coating for enhanced environmental protection and DIN-rail mounting flexibility, GE IS230SNCIH6A suits remote or harsh-location deployments while maintaining tight integration with Mark VIe controllers. For teams planning expansions, retrofits, or replacements in aging Mark VIe systems, GE IS230SNCIH6A offers a dependable path to upgrade signal acquisition without overhauling the entire I/O infrastructure, preserving process control stability and minimizing downtime risks.

The GE IS230SNCIH6A operates as a discrete (digital) input module within GE’s Mark VIe / Mark VIeS control platform, designed for distributed I/O architectures that place processing close to field devices. It mounts on a compatible terminal board or base (often DIN-rail oriented for flexible installation), connecting directly to process wiring while communicating upstream via the high-speed IONet Ethernet link to the Mark VIe controller or I/O pack CPU. This positions GE IS230SNCIH6A in the field-level I/O layer, reducing long cable runs prone to noise and enabling localized diagnostics.

The module processes higher-voltage discrete inputs (typically 125 V DC class) with built-in optical isolation, surge suppression, and filtering to handle real-world transients and EMI common in power plants. Each channel includes status monitoring and fault reporting—detected via onboard circuitry and CPU software—visible through system diagnostics, LEDs (for power, fault, and channel health), and ToolboxST tools. It supports redundant configurations (e.g., dual or TMR I/O packs) for critical loops, ensuring continued scanning during single-point failures. In the broader stack, GE IS230SNCIH6A feeds clean, timestamped discrete data to controllers for logic execution, alarming, SOE recording, and historian storage, using Mark VIe protocols like IONet for synchronization and EGD for peer exchange where applicable.

This design allows hot-swappable replacement in many setups and integrates natively with Mark VIe firmware for advanced features like channel-level diagnostics and time-stamped events. Whether deployed in simplex racks for auxiliary systems or redundant clusters for core protection, GE IS230SNCIH6A bridges field discretes to control logic with the robustness needed for continuous, deterministic performance in turbine-centric industrial automation.

| Specification | Details |

|---|---|

| Model Number | IS230SNCIH6A |

| Brand | GE (General Electric) / Mark VIe |

| Type | Discrete (Digital) Input Module – High Voltage (125 V DC class) |

| Input Voltage | Nominal 125 V DC (range typically 100–150 V DC or per Mark VIe spec) |

| Operating Temp Range | -30 °C to +65 °C (extended for harsh environments) |

| Mounting Style | DIN-rail or terminal board base (Mark VIe compatible) |

| Dimensions | Compact DIN-rail form factor (exact varies; typical ~100–150 mm height) |

| Weight | Approx. 0.3–0.5 kg |

| Interface/Bus | IONet Ethernet to controller; internal pack diagnostics |

| Compliance | CE, UL, designed for industrial/hazardous locations per Mark VIe certs |

| Supported Protocols | Mark VIe IONet; ToolboxST integration; EGD where applicable |

| Typical Power Draw | Low (I/O pack dependent; ~few watts) |

- IS230SNCIH6A

Choosing GE IS230SNCIH6A delivers solid gains in signal trustworthiness and system resilience. Engineered for high reliability in turbine control and process control settings, its higher voltage capability and robust isolation minimize input-related faults in electrically noisy environments, reducing nuisance trips and supporting longer mean time between failures in 24/7 operations.

Practically, GE IS230SNCIH6A streamlines diagnostics with detailed channel health feedback in ToolboxST, enabling faster troubleshooting and predictive maintenance—technicians spot issues early without invasive testing. The conformal-coated design withstands humidity, dust, and vibration better than uncoated alternatives, cutting maintenance frequency in challenging plant areas. Integration remains straightforward in Mark VIe ecosystems—no custom adapters needed—freeing engineering effort for optimization rather than workaround fixes, and ultimately enhancing overall availability and safety compliance.

GE IS230SNCIH6A sees primary use in gas and steam turbine applications within power plants, including combined-cycle, peaking, and cogeneration facilities demanding critical system uptime. It’s deployed for monitoring high-voltage discrete signals like breaker positions, limit switches, or safety interlocks in protection systems, where precise detection supports rapid response to faults or permissive conditions during startups and transients.

In oil & gas sectors, such as compressor or pump drive turbines, GE IS230SNCIH6A handles inputs in vibration-intensive or remote installations, ensuring reliable status feedback under harsh conditions. Utility and industrial sites with Mark VIeS safety-focused controls leverage it for SIL-capable discrete acquisition in emergency shutdown or fire & gas loops. Across these, GE IS230SNCIH6A maintains high reliability I/O signals in industrial automation environments prioritizing deterministic performance, regulatory adherence, and minimal forced outages.

Here are some related or compatible products in the GE Mark VIe / Mark VIeS family:

IS230TNCIH4 – Related analog I/O module for mixed-signal needs in the same distributed architecture.

IS230SNCIH – Base or variant series discrete input module (check revision for exact match).

IS230TNEAH – Ethernet-based I/O pack that can host or interface with modules like GE IS230SNCIH6A.

IS230SNAIH2A – Analog input companion module for comprehensive I/O in Mark VIe racks.

IS220PDIAH1B – Pack-level digital input variant with similar functionality but different form.

IS200SRTDH2A – Termination board often paired with discrete input modules for wiring.

IS420UCSBH – Modern Mark VIe controller that supports IONet-connected I/O including this type.

IS230STCIH6A – Similar discrete input module with potential channel or voltage variations.

Before installing GE IS230SNCIH6A, confirm compatibility with your Mark VIe I/O pack base or terminal board (e.g., matching revision and keying) and verify IONet network addressing to avoid conflicts. Ensure input voltage matches field devices (125 V DC class) and provide proper grounding/shielding to suppress noise. Check ambient conditions against the -30 to +65 °C range, ensuring ventilation in enclosures. Update controller firmware if required and pre-test wiring polarity/signal levels to prevent startup faults.

Maintenance stays proactive yet minimal. Regularly view ToolboxST diagnostics and module LEDs for fault or health alerts—channel discrepancies or power issues prompt quick checks. Inspect terminal connections annually for corrosion or loosening, especially in corrosive atmospheres. Leverage onboard supervision for trend monitoring; no routine calibration needed due to solid-state inputs. In redundant setups, test failover periodically during outages to confirm uninterrupted operation. This routine keeps GE IS230SNCIH6A delivering consistent performance with low hands-on effort.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626