Description

Real-World Use & Application Scenarios

Where is this product used and why?

The RV33-1.3 is a compact, high-precision gearhead or servo drive component used in motion control architectures where accurate torque, smooth speed control, and reliable loading performance are essential. It’s commonly found in CNC machining, packaging lines, material handling, and automation cells where precise positioning and repeatable motion are required. The model name signals a specific gearset ratio and performance class within GE’s RV33 family, chosen to balance speed, torque, and physical footprint for a given machine topology. End users select this variant to achieve predictable drive characteristics, easy integration with standard servo amplifiers and controllers, and straightforward maintenance within a modular automation framework.

Product Introduction & Positioning

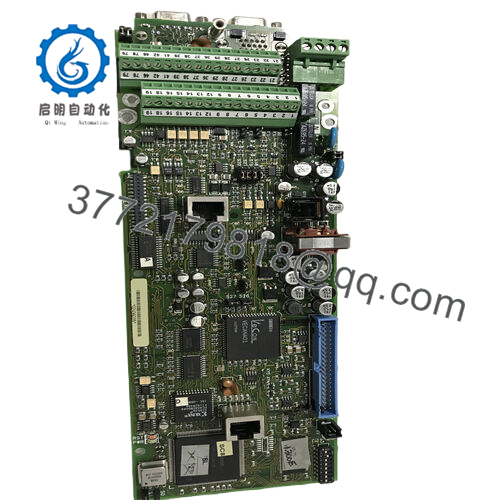

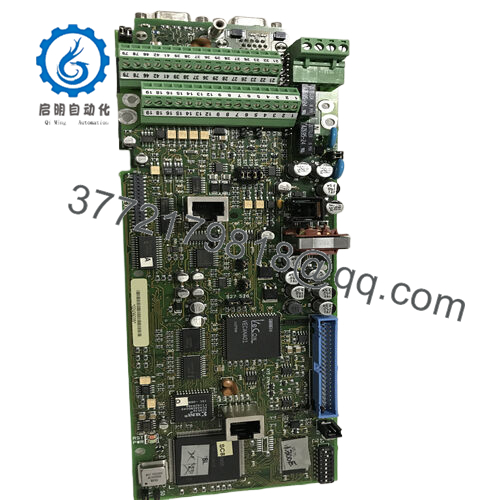

What it is, where it fits, and why it matters

GE RV33-1.3 refers to a geared drive component designed to couple a servo motor to a driven load with a defined gear ratio (the “1.3” hinting at a particular stage or variant rating in the family). It fits into GE’s motion control and drive systems where modular, scalable components reduce wiring complexity and simplify maintenance. This gearhead is positioned to deliver controlled torque transmission, consistent backlash, and reliable mechanical performance in a compact package, making it a preferred building block for machine builders who value repeatable precision and serviceability within GE’s automation ecosystem.

- RV33-1.3

Key Technical Features & Functional Benefits

Performance, reliability, and integration

Typical RV33-family gearheads emphasize precise backlash control, high-torque transmission, and robust mechanical design. The 1.3-series variant would be expected to offer a specific gear ratio, load rating, input shaft compatibility, and mounting options that align with GE servo drives and controllers. Benefits include smoother motion profiles, reduced load inertia impact on the motor, and improved positioning accuracy under varying loads. The drive’s compatibility with standard servo amplification and machine control software supports straightforward tuning, diagnostics, and lifecycle maintenance.

Installation Notes & Maintenance Best Practices

Two concise paragraphs

Before installation, verify the exact flange, shaft, and bore specifications to ensure proper mating with the servo motor and any coupling hardware. Confirm the enclosure, mounting clearance, and lubrication interval recommended by GE to maintain optimal gearhead performance. During commissioning, check backlash, run-in procedures, and load tests to verify that speed and torque targets are met without overshoot. Schedule periodic inspections of mounting bolts, seals, and lubrication levels, and track any wear indicators or vibration trends to prevent unexpected downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626