Description

In safety-critical process control environments where combustible gas leaks demand instantaneous detection to prevent explosions or operational halts, the Honeywell 05701-A-0302 delivers a focused safeguard for engineers dealing with the vulnerabilities of unmonitored catalytic sensors in hazardous zones. Picture a refinery distillation unit where delayed methane readings from pellistor-based detectors allow pockets to build undetected, risking ignition during maintenance, or a wastewater digester where hydrogen buildup evades early warning, triggering ventilation failures and compliance lapses—these threats often root in control cards that can’t interface cleanly with 4-20 mA sensor outputs or lack robust alarm thresholding amid variable ambient conditions. This single-channel catalytic control card overcomes them by acquiring linear current signals from bead-type gas sensors, applying configurable zero/span calibration and fault detection to generate precise alarm states, ensuring your response logic activates without hysteresis or drift-induced misses in real-time monitoring.

It becomes vital in industrial automation setups like oil and gas processing or sewage treatment, where high reliability in I/O signal conditioning for catalytic detectors upholds EN50270 performance standards and minimizes false positives that erode operator trust. The Honeywell 05701-A-0302 embeds into System 57 sub-racks, pairing seamlessly with power supplies like the 05701-A-0405 to drive one dedicated channel, so you avoid the sprawl of multi-sensor multiplexers while preserving signal integrity against bridge circuit imbalances. For teams upgrading legacy Zellweger or Sieger panels, it fits without protocol adapters, supporting field calibration via potentiometers that lock in linearity across gas ranges without full rack downtime. In distributed process control networks, its IP65 sealing and -40 to +80°C span handle corrosive vapors or thermal extremes, enabling remote deployments that scale sensor density without repeaters. By prioritizing catalytic-specific amplification and alarm relay interfacing, the Honeywell 05701-A-0302 enhances system stability, letting you prioritize threshold tuning and integration with PLCs rather than wrestling with sensor drift in high-stakes industrial automation deployments.

When evaluating detector interfaces for zone monitoring, the Honeywell 05701-A-0302 aligns for its sensor specificity and calibration ease, providing the conditioning reliability that anchors early detection in EMI-challenged or chemically aggressive settings.

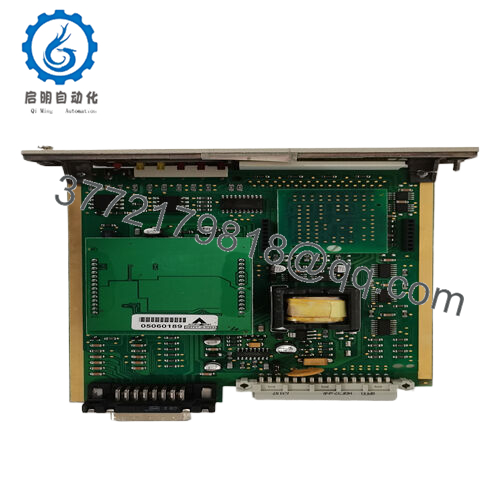

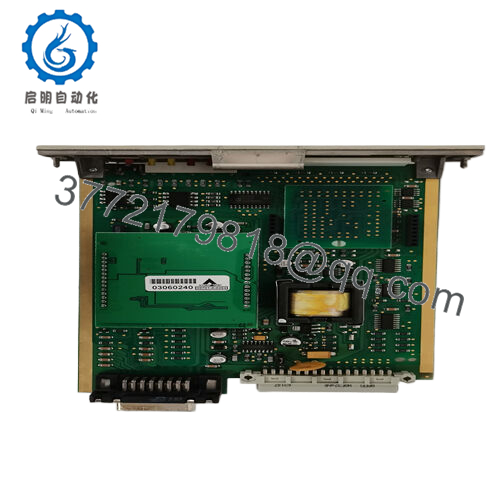

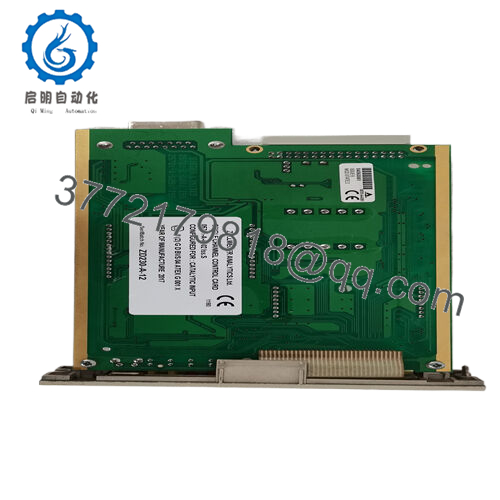

The Honeywell 05701-A-0302 acts as a single-channel analog input and control module in the sensor interface layer of Honeywell’s System 57 gas detection platforms, conditioning 4-20 mA signals from catalytic bead sensors into processed values for alarm generation and system diagnostics. It occupies one slot in 19-inch sub-racks (front- or rear-access), where its Wheatstone bridge circuitry amplifies resistance changes from combustible gases, applying linearization and temperature compensation to output scaled concentrations via the backplane bus to control processors or HMIs. This setup supports adjustable alarm setpoints for A1 (warning) and A2 (evacuation) thresholds, with relay outputs for direct effector wiring, and includes fault monitoring for sensor burnout or wire breaks, relaying status as 0-4 mA signals for upstream fault trees.

In a layered architecture, it draws 24 V DC from the rack PSU, interfacing downstream to pellistor detectors (e.g., 05701-A-0284) and upstream to relay cards like the 05701-A-0327 for output escalation, compatible with Modbus RS485 for remote setpoint queries. It adheres to EN50270 for sensor performance verification and supports hot-swappable insertion in live racks, with onboard potentiometers for zero/span tweaks during commissioning. Diagnostics encompass overrange flags or calibration drift alerts, feeding into event logs for predictive maintenance, and its modular design allows channel isolation up to 500 V to prevent ground loops in shared cabinets. Positioned at the field-to-logic boundary in your I/O stack, the Honeywell 05701-A-0302 optimizes detection architecture by dedicating amplification to one sensor, where screw terminals streamline screened cabling in explosion-proof enclosures—fostering a precise pathway that integrates with fire and gas panels via dry contacts, upholding response fidelity across HART-like overlays without introducing noise or calibration creep.

- 05701-A-0302

| Specification | Details |

|---|---|

| Model Number | 05701-A-0302 |

| Brand | Honeywell |

| Type | Single-Channel Catalytic Control Card |

| Input Voltage | 24 V DC |

| Operating Temp Range | -40°C to +80°C |

| Mounting Style | 19-inch Sub-Rack Slot |

| Dimensions | 17 x 2.5 x 11.2 cm |

| Weight | 0.165 kg |

| Interface/Bus | 4-20 mA Input, Relay Output |

| Compliance | CE, EN50270, RoHS |

| Supported Protocols | Modbus RS485 |

| Typical Power Draw | 3 W |

Deploying the Honeywell 05701-A-0302 equips your rack with conditioning precision that tracks gas levels to 0.1% LEL accuracy post-calibration, sidestepping the baseline shifts that mask low-level accumulations and delay ventilations in confined monitoring, which in turn refines threshold sensitivity and trims exposure risks in proactive sweeps. This fidelity extends to fault resilience, where burnout detection holds outputs low for safe defaults, often preempting sensor swaps in remote nodes.

Calibration aids further optimize field efficiency, with pot-based tweaks that restore linearity in minutes versus lab hauls for non-adjustable peers. Its sub-rack form trims deployment friction too—seating demands only backplane alignment and setpoint programming, not bus reconfigs, which reallocates engineering from sensor hunts to network zoning. Built for hazard endurance, it seals against 95% RH non-condensing and 10 g vibrations, with thermal compensation that steadies readings across extremes, to anchor long-term vigilance, keeping your System 57’s detection nerve keen through sensor rotations or ambient assaults.

In refinery pump houses, the Honeywell 05701-A-0302 conditions catalytic beads for propane watch, where its span holds amid oily mists and thermal swings to secure critical system uptime and spark-proofing in ceaseless process control.

Sewage lift stations harness it for H2S thresholds, amplifying bead outputs in humid, sulfide-laced vaults to drive high-reliability fan interlocks.

For offshore drilling mud pits, this control card parses methane from pellistors, meeting wave-motion and salt challenges with drift-free signaling that bolsters modular expansions in confined I/O safes.

05701-A-0301 – Analog 4-20 mA variant for non-catalytic sensors like electrochemical.

05701-A-0303 – Dual-channel edition for denser catalytic monitoring in multi-gas zones.

05701-A-0326 – Relay interface card for output escalation from the control card.

05701-A-0284 – Compatible catalytic sensor head for direct pairing.

05701-A-0405 – 16-way PSU for powering the control card in rack builds.

05701-A-0312 – Modbus RS485 module for networked setpoint adjustments.

05701-A-0331 – High-range catalytic variant for 0-100% LEL in fuel-rich areas.

Before integrating the Honeywell 05701-A-0302, verify sub-rack compatibility with EN50270 firmware, and adjust zero/span pots with a multimeter pre-energize to baseline at 4 mA—miscalibration amplifies offsets in low-gas states. Limit cable runs to 500 m with shielded twisted-pair to curb signal attenuation, and isolate sensor grounds from rack earth by 100 ohms to mute EMI, crucial in explosive-rated cabinets.

Upkeep spans quarterly bead resistance checks at 100 ohms nominal in corrosive airs, using a bridge meter to flag degradation below 95%. Poll alarm logs bimonthly via the diagnostics port to chart setpoint drifts, addressing variances over 5% with gas-span tests. Semiannual full-range simulations at 50% LEL confirm relay snap at 50 ms, and serial logging for rotation ties to audit cycles. This targeted vigilance meshes with your PM rhythm, staving off desensitizations that cloud detection acuity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626