Description

In safety-critical process control environments where gas detection alarms must trigger swift, isolated responses to avert leaks or exposures, the Honeywell 05701-A-0327 stands as an essential relay interface for engineers grappling with the need for clean, voltage-free signaling in multi-channel monitoring setups. Imagine a confined space in a chemical plant where a methane buildup goes unreported due to noisy relay contacts causing erratic actuations, or a battery room where hydrogen alarms fail to engage exhaust fans reliably, risking ignition and evacuation delays—these oversights often stem from relay cards that can’t deliver independent, fail-safe outputs amid shared power rails or EMI-laden enclosures. This double SPCO (single-pole changeover) relay card mitigates them by furnishing three dedicated, dry-contact relays for A1 and A2 alarm levels plus a fault channel, enabling direct wiring to strobes, horns, or PLC inputs without auxiliary isolators, so your interlocks activate decisively without false triggers or contact welding under load.

It emerges as a linchpin in industrial automation sectors like confined-space monitoring or battery management, where high reliability in discrete output signaling underpins EN50270-compliant detection and seamless integration with upstream controllers. The Honeywell 05701-A-0327 slots into System 57 sub-racks alongside control cards like the 05701-A-0301, drawing from the backplane’s 24 V DC to energize relays rated at 2 A resistive loads, ensuring galvanic separation that preserves I/O signal purity in dense cabinets. For teams sustaining legacy Sieger or Zellweger arrays, it aligns without reconfiguration, supporting hot-swappable insertion that keeps panels live during maintenance while bolstering fault tolerance against common-mode surges. In distributed process control frameworks, its compact form factor accommodates up to 16-way racks, facilitating expansions that handle escalating sensor counts without relay coalescence. By honing in on changeover versatility and contact durability, the Honeywell 05701-A-0327 augments system stability, letting you orchestrate alarm cascades with precision and redirect efforts from contact diagnostics to sensor optimization in rigorous industrial automation theaters.

When scrutinizing output interfaces for detection-centric architectures, the Honeywell 05701-A-0327 earns its slot for its output granularity and isolation prowess, supplying the actuation reliability that fortifies responses in vibration-prone or power-variable zones.

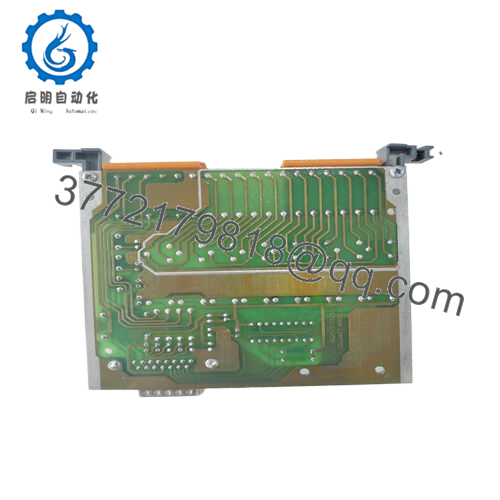

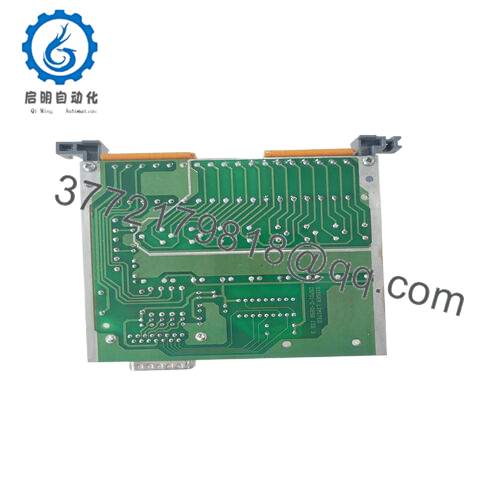

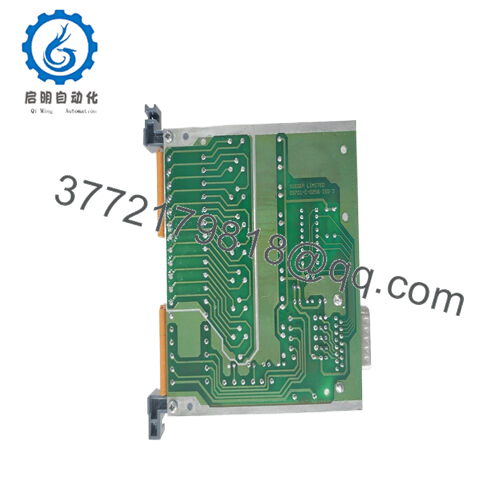

The Honeywell 05701-A-0327 operates as a relay output module in the signaling layer of Honeywell’s System 57 gas detection and alarm platforms, converting control card logic into electromechanical activations for external effectors like annunciators or shutdown valves. It installs into 19-inch sub-racks (front- or rear-access), occupying one slot where its three double SPCO relays—energized by backplane signals—provide voltage-free contacts for A1 (first-stage warning), A2 (critical alert), and fault/inhibit states, with changeover poles allowing common wiring for energized/de-energized schemes. This configuration supports up to 2 A at 30 V DC or 250 V AC resistive, with gold-alloy contacts for low-level switching down to 10 mA, ensuring reliable latching without bounce in sequential alarm propagation.

- 05701-A-0327

In a comprehensive hierarchy, it interfaces downstream to field effectors and upstream to analog control modules like the 05701-A-0302 for catalytic inputs, sourcing 24 V DC from the rack PSU while relaying coil status via LED indicators for visual confirmation or diagnostic polling. It integrates with Modbus RS485 for remote relay status queries and adheres to EN50270 for gas monitoring integrity, with built-in suppression diodes to quell back-EMF in inductive loads. Diagnostics include contact weld detection or coil failure alerts, feeding into event logs for HMI traceability, and its modular bays allow online swaps in populated racks. Positioned at the discrete output nexus in your I/O stack, the Honeywell 05701-A-0327 streamlines alarm architecture by consolidating relays per card, where screw terminals expedite cabling in marshalling panels—cultivating a responsive pathway that meshes with fire panels or PLCs via dry contacts, upholding signal isolation across protocol hybrids like HART without risking chatter or arc-induced faults.

| Specification | Details |

|---|---|

| Model Number | 05701-A-0327 |

| Brand | Honeywell |

| Type | Double SPCO Relay Card |

| Input Voltage | 24 V DC (backplane) |

| Operating Temp Range | -20°C to +50°C |

| Mounting Style | 19-inch Sub-Rack Slot |

| Dimensions | 30 x 130 x 200 mm (W x H x D) |

| Weight | 0.4 kg |

| Interface/Bus | Backplane, Dry Contacts |

| Compliance | CE, EN50270, RoHS |

| Supported Protocols | N/A (Relay Outputs) |

| Typical Power Draw | 3 W (all relays energized) |

Selecting the Honeywell 05701-A-0327 endows your rack with relay robustness that toggles A1/A2/fault channels independently at 50 ms response, quelling the crosstalk that muddles escalations and delays evacuations in layered alarms, which in turn hones response grading and curbs nuisance trips in sensor-dense grids. This discreteness excels in multi-zone configs, where changeover poles route to common effectors fluidly, empowering nuanced signaling that anticipates expansions without relay proliferation.

Contact hardening bolsters diagnostics too, with suppression that tamps inductive kicks for extended coil life, often doubling MTBF in solenoid-heavy runs versus unsuppressed peers. Its sub-rack seating trims integration loads as well—populating slots calls for terminal mapping only, not bus rewires, which frees engineering for logic sequencing over wiring mazes. Forged for panel persistence, it rides 10 g shocks and 95% humidity with sealed coils, at 1 million operations minimum, to cement long-term actuation fidelity, keeping your System 57’s alert core vigilant through zone proliferations or ambient assaults.

In petrochemical tank farms, the Honeywell 05701-A-0327 actuates perimeter strobes for VOC thresholds, where its dry contacts endure humid, explosive milieus to anchor critical system uptime and containment protocols in perpetual process control.

Battery storage vaults harness it for H2 fan relays, channeling fault outputs amid electrolyte vapors to enforce high-reliability ventilation interlocks.

For mining methane sentries, this relay card drives siren cascades, meeting seismic and dust rigors with bounce-free switching that sustains continuous monitoring in modular, expandable sub-racks.

05701-A-0328 – Triple SPCO variant for A1/A2/A3 plus fault in escalated alarm schemes.

05701-A-0329 – Triple DPCO model for dual-pole outputs in high-power effectors.

05701-A-0330 – High-integrity relay card for SIL-rated interlocks with dual contacts.

05701-A-0301 – Compatible 4-20 mA control card for analog input pairing.

05701-A-0326 – Field interface card for sensor-only inputs without relays.

05701-A-0405 – 16-way PSU for powering relay cards in dense racks.

05701-A-0312 – Modbus RS485 module for remote relay status integration.

Before fielding the Honeywell 05701-A-0327, confirm sub-rack firmware supports EN50270 diagnostics, and torque relay terminals to 0.8 Nm to resist vibration loosening—overtightening can fatigue strands. Balance coil loads under 1.5 A per relay to dodge heat buildup, and segregate contact wiring from power lines by 150 mm to mute induction, pivotal in cabinets near pumps.

Preservation spans quarterly contact resistance checks with a micro-ohmmeter targeting <50 mΩ per pole, especially in sulfurous process airs, paired with a dry brush for dust from vents. Harvest coil stats bimonthly through the engineering pane to trend activation cycles, isolating spikes over 10% for suppression audits. Semiannual dry-circuit tests at 5 V/1 mA validate changeover integrity, and serial tagging for rotation meshes with safety audits. This crisp regimen syncs with your PM tempo, forestalling chatter that blurs alarm clarity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626