Description

In process control environments where combustible gas detection must deliver unerring sensitivity to avert explosions, leaks, or ventilation delays in hazardous zones, the Honeywell 05704-A-0144 emerges as a pivotal safeguard for engineers facing the inconsistencies of multi-sensor integration under variable field loads. Imagine a compressor station in a natural gas pipeline where catalytic bead drift from unbalanced bridge circuits masks low-level methane buildup, triggering false negatives that compromise safety interlocks, or a solvent storage facility where channel crosstalk in humid enclosures leads to erratic LEL readings, escalating risks during loading operations—these vulnerabilities often trace to control cards that falter at sustaining constant current across four sensors or lack granular fault isolation in EMI-saturated backplanes. This four-channel catalytic control card confronts them by powering and conditioning 4-20 mA signals from bead-type detectors with electronic current adjustment from 90-315 mA in 1 mA steps, applying ±1% initial accuracy to generate precise concentration outputs for alarm thresholding, ensuring your response logic engages fluidly without baseline wander or overload-induced dropouts in real-time surveillance.

It gains indispensable status in industrial automation realms like oil and gas compression or chemical warehousing, where high reliability in I/O signal processing for catalytic inputs underpins EN50270-compliant performance and seamless tie-ins to DCS or PLCs. The Honeywell 05704-A-0144 deploys in System 57 sub-racks, interfacing directly with power supplies like the 05704-A-0405 to drive up to four channels independently, so you circumvent the limitations of single-channel units while upholding signal integrity against common-mode voltages up to 500 V. For those sustaining legacy Sieger or Zellweger panels amid expansions, it slots in without protocol adapters, enabling hot-swappable upgrades that preserve wiring while enhancing diagnostics for sensor burnout or wire faults. In distributed process control setups, its compact 1U height and 0-100% LEL span adapt to corrosive vapors or thermal swings from -20°C to +50°C, facilitating node scaling that accommodates growing detector arrays without repeaters. By centering on multi-channel constancy and electronic tuning, the Honeywell 05704-A-0144 reinforces system stability, letting you prioritize LEL zoning and integration with fire panels rather than chasing contact imbalances in high-stakes industrial automation frameworks.

When evaluating catalytic interfaces for zone coverage, the Honeywell 05704-A-0144 merits review for its channel efficiency and current precision, supplying the conditioning reliability that synchronizes multi-sensor arrays without sacrificing response times in vibration-prone or humidity-laden deployments.

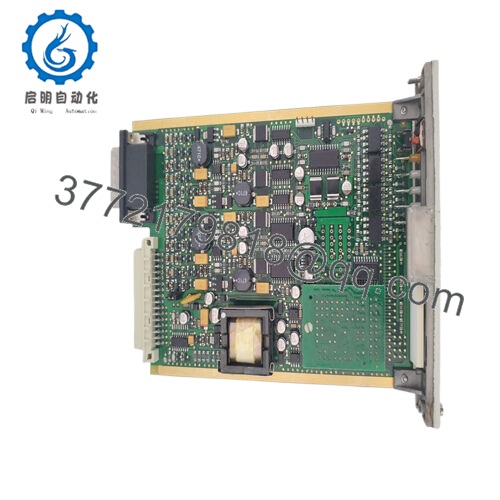

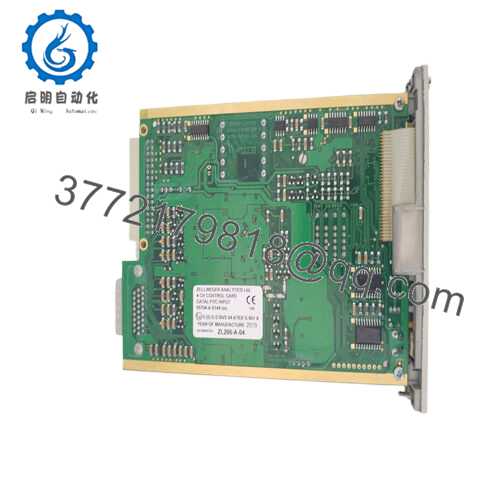

The Honeywell 05704-A-0144 functions as a four-channel catalytic input control card in the sensor processing layer of Honeywell’s System 57 gas detection platforms, acquiring and linearizing 4-20 mA signals from pellistor bead detectors into scaled LEL values for upstream alarm logic or HMIs. It occupies a single slot in 19-inch sub-racks (front- or rear-access variants), where each channel employs constant-current drive circuitry to energize sensors at adjustable levels (90-315 mA), compensating for temperature and poisoning effects via onboard amplification and zero/span pots for field tuning, outputting processed data via the backplane bus with 0.1% resolution. This setup supports independent fault detection per channel, such as burnout (output <1 mA) or overrange (>22 mA), relaying alerts as discrete flags for escalation to relay cards or Modbus networks.

- 05704-A-0144

In a layered configuration, it sources 24 V DC from the rack PSU, connecting downstream to catalytic heads (e.g., 05704-A-0284) and upstream to output modules like the 05704-A-0327 for effector activation, compatible with RS485 for remote setpoint polling in distributed nodes. It adheres to EN50270 for detector verification and enables hot-swappable operation in live racks, with LED indicators for channel status or calibration modes. Diagnostics include drift thresholds or bridge imbalance warnings, feeding into event logs for predictive swaps, and its modular bays isolate channels up to 1500 V to prevent crosstalk in shared enclosures. Positioned at the detector-to-logic interface in your I/O stack, the Honeywell 05704-A-0144 optimizes gas monitoring by multiplexing four inputs efficiently, where screw terminals expedite screened cabling in explosion-proof housings—cultivating a responsive pathway that integrates with safety PLCs via dry contacts, upholding LEL accuracy across HART extensions without introducing ripple or poisoning offsets.

| Specification | Details |

|---|---|

| Model Number | 05704-A-0144 |

| Brand | Honeywell |

| Type | 4-Channel Catalytic Control Card |

| Input Voltage | 24 V DC |

| Operating Temp Range | -20°C to +50°C |

| Mounting Style | 19-inch Sub-Rack Slot |

| Dimensions | 30 x 130 x 200 mm (W x H x D) |

| Weight | 0.4 kg |

| Interface/Bus | Backplane, 4-20 mA Inputs |

| Compliance | CE, EN50270, RoHS |

| Supported Protocols | Modbus RS485 |

| Typical Power Draw | 8.5 W (typical); 12.8 W max |

Incorporating the Honeywell 05704-A-0144 fortifies your sub-rack with current stability that locks in ±1% accuracy across 0-100% LEL spans post-tuning, quashing the drift that obscures trace leaks and delays purges in zoned monitoring, which in turn tightens alarm gradients and curtails exposure incidents in proactive sweeps. This granularity extends to fault handling, where per-channel burnout flags default outputs safely for uninterrupted coverage, often forestalling full-panel outages in remote setups.

Electronic adjustments sharpen maintenance too, with 1 mA granularity that restores balance in minutes via pots, versus lab recalibrations for fixed-drive peers. Its rack-slot footprint eases scaling burdens as well—adding channels involves backplane alignment only, not bus rewires, which reallocates engineering from sensor hunts to zoning refinements. Built for enclosure tenacity, it withstands 10 g vibrations and 95% humidity with sealed pots, at 500,000 hour MTBF, to anchor long-term vigilance, keeping your System 57’s catalytic nerve attuned through detector rotations or ambient assaults.

In natural gas metering stations, the Honeywell 05704-A-0144 conditions four bead inputs for LEL oversight, where its constant drive endures dusty, pressure-variable vaults to secure critical system uptime and flow safeguards in continuous process control.

Offshore drilling derricks deploy it for enclosure gas watch, parsing multi-channel outputs amid salty, vibratory holds to drive high-reliability interlocks.

For paint booth ventilation in automotive assembly, this control card aggregates solvent vapors, meeting airflow and solvent challenges with tuned precision that bolsters modular expansions in confined I/O safes.

05704-A-0301 – Single-channel analog variant for non-catalytic electrochemical sensors.

05704-A-0303 – Eight-channel catalytic upgrade for denser zone monitoring.

05704-A-0327 – Relay output card for escalating alarms from the control card.

05704-A-0284 – Compatible catalytic bead sensor for direct field pairing.

05704-A-0405 – 16-way PSU for powering multi-channel control cards in racks.

05704-A-0312 – RS485 comms module for networked diagnostics and setpoints.

05704-A-0145 – Enhanced four-channel model with integrated surge protection.

Before fielding the Honeywell 05704-A-0140, confirm sub-rack firmware supports EN50270 fault codes, and tweak current pots with a DMM pre-power-up to 150 mA baseline—overdriving risks bead burnout in low-gas states. Cap cable lengths at 300 m with shielded pairs to curb attenuation, and isolate sensor grounds from rack earth by 100 ohms to damp EMI, essential in explosive-rated cabinets.

Upkeep encompasses quarterly bridge resistance checks at 100 ohms nominal in corrosive airs, using a Wheatstone meter to spot degradation below 95%. Poll channel logs bimonthly via the diagnostics port to trend LEL drifts, addressing variances over 2% with span gas tests. Semiannual full-range simulations at 50% LEL validate output snap at 100 ms, and serial tagging for rotation ties to audit cycles. This vigilant protocol dovetails with your PM rhythm, staving off desensitizations that cloud gas acuity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626