Description

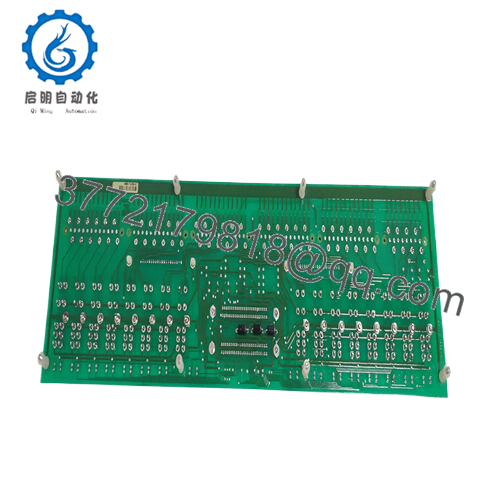

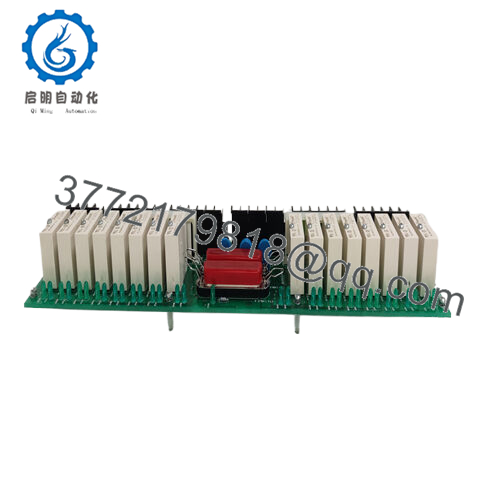

Product Model: 51304441-275 (MC-TDID52)

Product Brand: Honeywell

Product Series: MC / Digital Input Modules

Key Features:

- 32 discrete digital input channels, designed for 24 VDC signals (e.g. switches, proximity sensors)

- Screw-terminal connections for each input point, robust for industrial wiring

- Input isolation and field-to-safe area interface (digital input FTA format)

- Supports redundancy / CE compliance; conformal-coated versions available

- 51304441-275 MC-TDID52

Product Role & System Fit

The Honeywell 51304441-275 MC-TDID52 is a 32-channel digital input module intended for industrial control and safety systems. Typically used in Honeywell FTA (Field Terminal Assembly) or I/O systems, this module converts real-world discrete signals—switch closures, alarm contacts, proximity sensor outputs—into digital data that the control logic can read.

In architectures where field circuits may be hazardous or require isolation, this module (often categorized under “Digital Input FTA 24 VDC”) bridges the gap: inputs from the hazardous area connect into this module, which isolates and formats them safely toward the control system. The spec description states it “accommodates up to 32 switch or proximity detector inputs from a hazardous area” and isolates them for safe processing.

It finds its place in I/O racks, termination assemblies, or safety/instrumentation panels, typically serving as the first stage of discrete signal acquisition. Typical use cases: monitoring level switches, safety interlock contacts, door sensors, fault alarms, pump status, limit switches, etc.

Because it handles many points (32), it is efficient in dense installations. Its modular nature allows you to scale discrete input capacity while maintaining standard wiring practices and diagnostics.

Technical Features & Benefits

Here’s a deeper look into what the 51304441-275 MC-TDID52 module brings to the table, from specification to practical value.

Channel Count & Input Spec

- It handles 32 discrete inputs (32 points) for 24 V DC logic inputs.

- The inputs typically accept “dry contact” or active 24 V DC signals (e.g. sinking or sourcing switches)

- The screw-terminal style allows for individual wire connections and secure retention suitable for field wiring environments

Isolation, Redundancy & Compliance

- The module is described as a “Digital Input FTA”, meaning it is part of the Field Termination Assembly that isolates hazardous-area signals into the safe side.

- It is CE-compliant and available in conformal coated versions; the part number ending “-275” is among those CE versions of FTA modules.

- The design supports redundancy, meaning you can plan failover paths or backup modules in mission-critical systems.

Physical and Mechanical

- According to one distributor, the physical size is ~ 16.5 cm × 7.5 cm × 12 cm, and weight ~ 0.53 kg

- Other listings support that dimension class for the module, fitting it into standard panel / rack spaces.

- The module uses screw terminals for inputs.

Use in Hazardous / Field Applications

- The module accommodates inputs from hazardous area circuits (e.g. proximity sensors, temperature thresholds, level sensors) and brings them into safe logic domains.

- It features input isolation (field-to-safe) to protect the internal logic and prevent faults from propagating.

- Multiple modules may be mounted with environmental or mechanical protection (e.g. conformal coating) for rugged field use.

Because digital input modules are fundamental for discrete control (on/off logic), a reliable and well-isolated design like this is crucial for safety, diagnostics, and signal integrity in industrial systems.

Technical Specifications Table

Below is a compiled spec table using sourced info and reasonable assumptions. Always verify with your module’s datasheet or label.

| Specification | Value / Range | |

|---|---|---|

| Model | 51304441-275 (MC-TDID52) | |

| Module Type | Digital Input Module / FTA | |

| Number of Inputs | 32 discrete channels | |

| Input Voltage | 24 V DC | |

| Terminal Style | Screw terminals | |

| Isolation | Field-to-safe (input isolation) | |

| Compliance | CE (conformal coat), redundancy support | |

| Physical Dimensions | ~16.5 × 7.5 × 12 cm | |

| Weight | ~0.53 kg | |

| Use Case | Switch / proximity sensor input, hazardous area | |

| Channel Grouping / Return | 32 individually isolated inputs (no common return grouping) | Implied by “32 individually isolated ac inputs” from spec list |

This table gives you a good baseline — but be sure to cross-check labeling on your unit for revision, terminal numbering, and isolation class.

Installation & Maintenance Insights

Below are practical recommendations and tips from field experience when installing or servicing the MC-TDID52 / 51304441-275 module.

Mounting & Rack Placement

- Mount the module securely in its intended rack, FTA panel, or I/O housing. Ensure the module is properly aligned and contacts fully engage the backplane or connector.

- Leave adequate clearance for wiring, ventilation, and maintenance access, especially around the screw terminal area.

- Use conformal-coated or sealed enclosures if the environment is humid, dusty, or corrosive (some versions of this module are available with conformal coating)

Wiring & Input Connections

- Use properly rated wires for 24 V DC input circuits; size cables to avoid voltage drop over long runs.

- Terminate wires with ferrules or proper connectors for screw terminals to avoid stray strands.

- Protect wires from abrasion, routing them away from power cables or high-noise sources.

- Grounding: ensure module chassis or housing is grounded to reduce interference and provide a return reference.

Signal Quality & Diagnostic Checks

- After wiring, test each discrete input (apply 24 V signal or closure) and verify that the module reads “ON” (logic high) in the system.

- Check for stuck inputs or ghost signals (wiring leakage or induced noise) — good isolation in the module helps, but field wiring layout is critical.

- Periodic inspection: look for loose connections, corrosion, terminal torque loosening, and physical damage.

- Use diagnostics or system logs (if supported) to detect channel faults, stuck bits, or isolation failures.

Replacement & Spares Strategy

- Always keep at least one spare MC-TDID52 module (or equivalent) in your inventory — discrete modules are often in high demand and have long lead times.

- During replacement, ensure the new module matches the same part number, revision, and conformal / isolation variant.

- Test the new module offline (with dummy inputs) before deploying into live systems to catch faults early.

Redundancy & Safety Considerations

- If your system supports redundant I/O or backup modules, ensure that channel mapping and failover logic are correctly configured so that critical inputs stay covered.

- Be cautious with wiring changes in hazardous circuits—always de-energize before servicing.

- For high-safety or SIL systems, document module calibration, field wiring, and replacement history to support audits.

Related / Companion Modules

Some modules often paired or used alongside the MC-TDID52 module include:

- Digital Output (DO) modules (e.g. MC-TDOD series) to drive relays, actuators, etc.

- Analog Input / Output modules when signal-level or continuous measurement is required.

- I/O backplane / terminal assemblies / Field Termination Assemblies (FTA) modules that connect field wiring to the safe domain.

- Conformal coated or redundancy variants of the same digital input model (e.g. CE or non-CE versions)

- Controller / logic modules that consume the discrete inputs for logic or monitoring (e.g. Honeywell control processors)

These modules often share mechanical footprints, bus interfaces, and diagnostics frameworks, making integration and spares management simpler.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626