Description

In process control systems where seamless data exchange between local controllers and central networks is crucial to avoiding communication silos or latency-induced faults, the Honeywell 51304511-200 emerges as a key enabler for engineers contending with the complexities of hybrid legacy-modern architectures. Envision a refinery control room where disjointed Universal Control Network (UCN) updates from remote process modules delay operator visibility, risking overlooked pressure anomalies or inefficient valve sequencing, or a chemical plant’s Local Control Network (LCN) where intermittent node handoffs cascade into production halts and safety overrides—these friction points frequently arise from interface modules that can’t bridge high-speed serial links reliably amid EMI or protocol variances. This CE-compliant NIM Modem I/O module counters them by providing robust interconnection between the UCN and LCN, facilitating redundant data routing for up to 100 Mbps throughput while embedding fault diagnostics to detect cable integrity or sync losses proactively, ensuring your point databases and control blocks synchronize without gaps in real-time operations.

It proves essential in industrial automation environments like hydrocarbon refining or continuous chemical processing, where high reliability in network interfacing underpins seamless scalability and regulatory compliance for distributed nodes. The Honeywell 51304511-200 pairs with the Enhanced Process Network Interface (EPNI) board (51401583-100) in TDC 3000 or Experion PKS setups, supporting dual-redundant cabling for failover under 50 ms to maintain uninterrupted traffic between xPM/LM nodes and their databases, so you avoid the single-point vulnerabilities of non-CE legacy variants. For teams modernizing older PNI/PNM configurations, it overlays without full bus rewiring, easing integration by preserving existing UCN topology while boosting signal integrity against common-mode noise up to 500 V. In expansive process control frameworks, its paddle-board design with mini-coax connectors accommodates dense rack deployments, enabling modular expansions that handle growing LCN traffic without repeaters or custom gateways. By focusing on CE-compliant connectivity and redundancy, the Honeywell 51304511-200 fortifies system stability, empowering unified network oversight that aligns with operational agility and reduces the engineering drag of mismatched interfaces in rigorous industrial automation ecosystems.

When evaluating network bridges for resilient DCS stacks, the Honeywell 51304511-200 warrants consideration for its redundancy focus and CE adherence, delivering the interfacing reliability that unifies UCN/LCN flows without introducing bottlenecks in EMI-prone or cable-extended deployments.

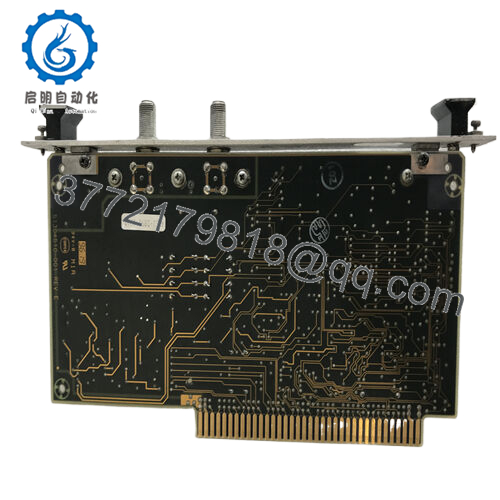

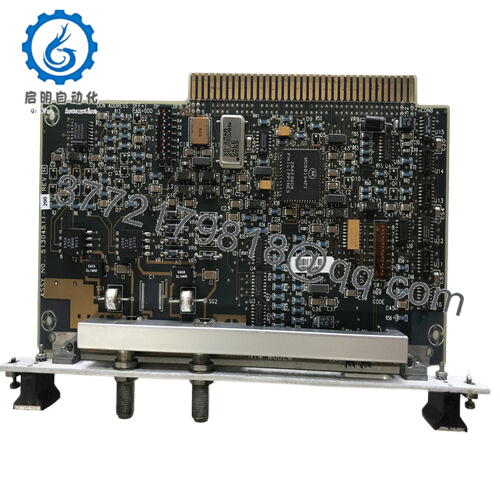

The Honeywell 51304511-200 serves as the CE-compliant I/O interface board for the Network Interface Module (NIM) in Honeywell’s TDC 3000 and compatible distributed control systems, acting as the physical and logical bridge between the Universal Control Network (UCN) and Local Control Network (LCN). It mounts as a paddle card on the EPNI main logic board (51401583-100), utilizing mini-coax connectors for A/B redundant UCN cabling to route serial data packets at up to 100 Mbps, supporting cyclic polling of up to 32 nodes with embedded CRC checks for error-free transmission. This configuration enables bidirectional flow of point data, control commands, and diagnostics between LCN-resident xPM/LM modules and central databases, with automatic failover on primary path faults to preserve scan continuity.

In a typical hierarchy, it draws 24 V DC from the NIM chassis power supply, interfacing upstream to UCN highways and downstream to LCN Ethernet or serial segments for hybrid topologies, while integrating with redundancy managers for hot-standby switching under 50 ms. It complies with CE standards for EMC and safety, supporting protocols like Modbus RTU for legacy extensions, and onboard diagnostics monitor link status or sync discrepancies, relaying alerts via SNMP to HMIs for preemptive cable swaps. Positioned at the network demarcation in your I/O architecture, the Honeywell 51304511-200 streamlines connectivity by consolidating modem functions into a single board, where its gold-plated contacts facilitate secure terminations in rack-mounted enclosures—fostering a fault-tolerant pathway that scales with Profibus overlays, upholding packet integrity across backplane-shared setups without latency spikes or reconfiguration needs.

- 51304511-200

| Specification | Details |

|---|---|

| Model Number | 51304511-200 |

| Brand | Honeywell |

| Type | NIM Modem I/O Interface Board (CE Compliant) |

| Input Voltage | 24 V DC |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | Paddle Board on EPNI (Rack Mount) |

| Dimensions | 250 x 100 x 25 mm (approx.) |

| Weight | 0.45 kg |

| Interface/Bus | Mini-Coax UCN, Serial LCN |

| Compliance | CE, EN 50270, RoHS |

| Supported Protocols | Modbus RTU, Proprietary UCN |

| Typical Power Draw | 4 W |

Opting for the Honeywell 51304511-200 integrates a modem engineered for unwavering link stability, sustaining 100 Mbps UCN throughput across redundant paths to quell the sync drifts that fragment databases and delay interlocks in multi-node clusters, which in turn refines control granularity and trims variances in process variables like flow or composition. This endurance shines in redundancy-heavy setups, where A/B failover preserves traffic seamlessly, often confining disruptions to milliseconds and bolstering confidence in 24/7 uptime for safety-critical loops.

Diagnostics precision further refines upkeep, with contact monitoring that surfaces cable faults via LED cues for targeted interventions, slashing troubleshooting to under 30 minutes against hours for opaque legacy boards. Its paddle form trims scaling friction too—pairing with EPNI demands only coax alignment, not bus reconfigs, which lightens engineering for topology tweaks over hardware hunts. Built for rack resilience, it withstands 5 g vibrations and 95% humidity with conformal coatings, at 1 million mate/unmate cycles, to lock in long-term connectivity, keeping your TDC core adaptive to node surges or protocol evolutions gracefully.

In refinery distillation towers, the Honeywell 51304511-200 links remote xPM nodes to central LCN for level cascading, where its CE isolation endures humid, EMI-riddled housings to enforce critical system uptime and cut-point fidelity in ceaseless process control.

Power utility substations deploy it for breaker status polling over UCN, handling fast data cycles amid transient-heavy zones to synchronize high-reliability grid responses.

For pharmaceutical HVAC clusters, this interface bridges LM controllers for air handler sequencing, meeting cleanroom constraints with redundant links that underpin modular expansions in expansive I/O vaults.

51304511-100 – Non-CE variant for legacy UCN/LCN bridging in non-regulated setups.

51401583-100 – Companion EPNI main logic board for full NIM assembly.

51305896-200 – Updated CE NIM I/O replacement for enhanced diagnostics.

51195153-005 – Redundancy manager module for pairing with NIM in duplex configs.

51195096-200 – Fan assembly add-on for cooling EPNI/NIM in dense racks.

AC02W36-L0481 – Alternative modem card for hybrid serial integrations.

51304501-100 – PMM redundancy module for UCN failover alongside NIM.

Before deploying the Honeywell 51304511-200, verify EPNI firmware compatibility at version 10.x or later for CE modem handshaking, and torque coax connectors to 0.5 Nm to resist vibration loosening—loose fits amplify packet errors in EMI zones. Balance UCN cable lengths under 100 m per segment to cap attenuation, and shield mini-coax runs from power lines by 200 mm to mute crosstalk, especially in cabinets near drives.

Maintenance centers on quarterly contact resistance probes at <50 mΩ with a micro-ohmmeter in humid process bays, ensuring snug fits without residue bridging. Query link stats bimonthly via the engineering console to trend sync variances, addressing drifts over 2% with cable swaps. Semiannual redundancy tests by simulating primary faults validate failover under load, confirming sub-50 ms handoffs, and archiving config files aids rapid interchanges. This pragmatic routine aligns with your PM cadence, forestalling outages that fragment network oversight.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626