Description

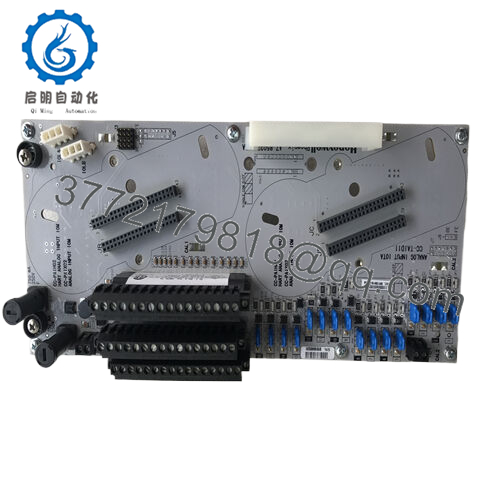

In process control environments where field signals from differential transmitters require uncompromised noise rejection to avert measurement inaccuracies or loop instabilities, the Honeywell CC-TAID11 steps in as a resilient interface for engineers navigating the demands of redundant I/O in noisy, high-stakes setups. Picture a distillation tower in a refinery where common-mode interference from long cable runs corrupts pressure differentials, yielding skewed level readings that cascade into off-spec fractions or overfills, or a compressor skid in gas processing where voltage imbalances across sensor pairs trigger spurious alarms, disrupting throughput and inviting unnecessary interventions—these pitfalls often originate from termination assemblies that can’t decouple signals effectively amid EMI or ground potentials in shared cabinets. This redundant differential analog input IOTA resolves them by providing isolated field wiring for 16 channels (12 single-ended and 4 differential) with 70 dB CMRR to filter out up to 500 Ω source imbalances, ensuring clean transmission to your C300 controller without the need for external filters or baluns, so your control actions stay precise and responsive in dynamic field conditions.

It shines brightest in industrial automation landscapes like hydrocarbon refining or power utilities, where high reliability in I/O signal termination underpins seamless redundancy and regulatory adherence for continuous operations. The Honeywell CC-TAID11 anchors Experion PKS Series-C architectures, linking directly to modules like the CC-PAIH02 for voltage/current handling from 2-wire or self-powered transmitters, supporting galvanic isolation that buffers peaks up to 5 V while accommodating 12-foot cable lengths for flexible field routing. For those extending legacy TPS nodes, it bridges without major rewiring, easing upgrades by preserving compatibility with existing marshalling while enhancing fault tolerance against transients in vibration-laden enclosures. In expansive process control deployments, its redundant design enables automatic failover for uninterrupted signal paths, facilitating scalable expansions that handle fast scan rates without latency creep. By emphasizing differential integrity and modular redundancy, the Honeywell CC-TAID11 bolsters system stability, allowing tighter setpoint tracking and reduced variance that directly boosts efficiency, all while lightening the engineering load of field termination in rigorous industrial automation frameworks.

When evaluating IOTA options for noise-resilient stacks, the Honeywell CC-TAID11 aligns for its channel mix and failover readiness, delivering the termination reliability that safeguards signals in EMI-saturated or cable-extended environments without sacrificing deployment speed.

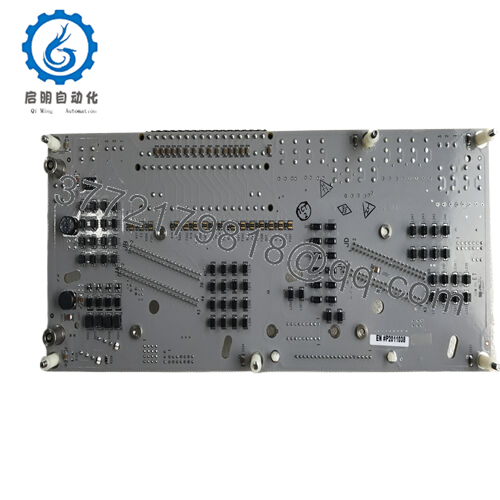

The Honeywell CC-TAID11 operates as a redundant differential analog input IOTA (Input/Output Terminal Assembly) in the field termination layer of Honeywell’s Experion PKS Series-C distributed control systems, routing voltage or current signals from transmitters to the C300 I/O module while providing isolation and redundancy for fault-tolerant operation. It mounts via compression terminals in marshalling cabinets or sub-racks, supporting 16 channels—12 single-ended for standard inputs and 4 differential for high-precision pairs—with 250-ohm shunts for 4-20 mA compatibility and 16-bit A/D readiness upstream. This setup decouples common-mode voltages (-6 to +5 V peak) through 70 dB rejection up to 60 Hz, enabling bidirectional HART passthrough on compatible modules for device diagnostics without analog interruption, while redundant wiring allows seamless failover in dual-path configurations to preserve scan continuity under 50 ms.

- CC-TAID11

In a layered stack, it interfaces downstream to field devices and upstream to the Series-C bus via the C300 carrier, drawing minimal power while relaying status through the module’s diagnostics for open circuits or overrange alerts to HMIs. It pairs with non-redundant siblings like the CC-TAID01 for hybrid nodes, handling scan rates to 100 ms per channel and complying with FOUNDATION Fieldbus for extensions, with per-channel isolation up to 1500 V to curb crosstalk. Positioned at the field-to-backplane boundary, the Honeywell CC-TAID11 streamlines I/O architecture by consolidating terminations in a 12-foot assembly, where screw blocks facilitate screened cabling in enclosures—cultivating a resilient pathway that integrates with safety systems via Profisafe, upholding signal purity across topologies without introducing ground loops or reconfiguration hurdles.

| Specification | Details |

|---|---|

| Model Number | CC-TAID11 |

| Brand | Honeywell |

| Type | Redundant Differential Analog Input IOTA (16-ch) |

| Input Voltage | 24 V DC (from C300 carrier) |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | Marshalling Cabinet / Sub-Rack |

| Dimensions | 12 ft length (redundant cable) |

| Weight | 1.2 kg |

| Interface/Bus | Compression Terminals, Series-C Bus |

| Compliance | CE, IEC 61131-2, RoHS |

| Supported Protocols | HART, FOUNDATION Fieldbus |

| Typical Power Draw | 2 W |

Integrating the Honeywell CC-TAID11 arms your C300 with termination endurance that locks in 70 dB noise suppression across differential pairs, staving off the imbalances that warp baselines and loosen PID grips in long-run field loops, which in turn hones measurement fidelity and trims deviations in variables like differential pressure or flow without added isolators. This robustness extends to redundancy wiring, where mirrored paths mask faults transparently to keep inputs streaming, often slashing recovery to seconds in monitored grids and fostering trust in automated safeguards over manual polls.

Isolation depth refines field care too, with terminal diagnostics that spotlight channel glitches for targeted fixes, confining downtime to minutes in zoned setups versus hours for unmonitored cables. Its IOTA form trims deployment loads as well—snaking 12-foot assemblies demands only terminal mapping, not panel rebuilds, which reallocates engineering from routing mazes to loop validation. Forged for cabinet grit, it weathers 10 g shocks and 95% humidity with sealed compression points, buffering 500 V surges to undergird long-term clarity, keeping your PKS frontier attuned to field nuances through expansions or surge events gracefully.

In crude distillation units, the Honeywell CC-TAID11 routes differential level signals from guided-wave radars, where its CMRR endures steamy, EMI-choked housings to lock in critical system uptime and fraction purity in ceaseless process control.

Gas compressor interstage monitoring leverages it for pressure pair inputs, handling fast data cycles amid vibratory, hydrocarbon-laced zones to synchronize high-reliability throttling.

For pharmaceutical autoclave controls, this IOTA aggregates steam probe differentials, meeting sterile constraints with redundant paths that enable modular cabinet growth in expansive I/O marshalling.

CC-TAID01 – Non-redundant differential counterpart for single-path field terminations in less critical loops.

CC-TAIX11 – Redundant single-ended variant for high-channel density without differential needs.

CC-TAIN11 – Thermocouple-focused redundant IOTA for temperature-heavy field wiring.

CC-PAIH02 – Matching 16-channel input module for HART-enabled signal processing upstream.

CC-GAIX11 – Galvanic-isolated redundant edition for hazardous zone field extensions.

DC-TAIDx1 – Non-redundant IOTA base for hybrid single-ended/differential setups.

CC-PDOB01 – Redundant output IOTA for balanced bidirectional field interfacing.

Before wiring the Honeywell CC-TAID11, align with C300 firmware at version 10.x or later for full redundancy polling, and torque compression terminals to 0.6 Nm to seal against vibration—loose grips amplify noise in dynamic mounts. Gauge cable asymmetry under 500 Ω per pair to uphold CMRR, and braid shields grounded solely at the IOTA end to drain EMI without loops, vital in trays near solenoids.

Sustaining it calls for semiannual terminal inspections for oxidation in humid process bays, applying dielectric grease to contacts without bridging. Harvest diagnostics quarterly via the Experion console to chart isolation trends, flagging dips below 70 dB for cable audits. Biannual end-to-end tests with a 1 V differential source confirm 16-bit fidelity across channels, and tagging with run dates syncs with compliance checks. This lean protocol meshes with your PM tempo, preempting degradations that haze signal acuity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626