Description

In industrial automation environments where scaling control points without overhauling the entire rack becomes a bottleneck for efficiency, the Honeywell CP-EXPIO delivers a targeted expansion for engineers grappling with limited I/O capacity in compact plant controllers. Imagine overseeing a chilled water loop in a commercial building where adding sensors for demand management strains the base controller’s 128-point limit, leading to delayed responses or fragmented monitoring, or a small-scale manufacturing cell where output constraints hinder actuator integration, causing synchronization lags and throughput dips—these constraints often arise from modules that can’t extend seamlessly without custom cabling or protocol bridges. This expansion I/O board addresses them by bolting on up to 24 mixed inputs and outputs to compatible ComfortPoint Open (CPO) controllers, enabling up to 256 physical I/Os in total for firmware 2.1 and later, so you maintain granular oversight of analog and digital signals without sacrificing scan speed or introducing latency in real-time loops.

It gains traction in process control setups like HVAC optimization or light industrial sequencing, where high reliability in modular I/O extension underpins cost-effective scalability and seamless BACnet integration for building or plant-wide coordination. The Honeywell CP-EXPIO attaches via RS-485 daisy-chaining to CPO-IPC or CPO-PC-6A controllers, supporting up to 15 modules per IPC or 16 per PC-6A to distribute loads evenly, ensuring signal integrity against EMI in conduit-shared runs. For those retrofitting legacy Niagara-based nodes, it aligns without firmware overhauls, easing expansions by preserving existing JACE compatibility while boosting point density for trending or alarming. In distributed automation frameworks, its powerful onboard processor handles faster scanning for universal inputs and triac outputs, facilitating deployments that adapt to variable loads without repeaters. By prioritizing mixed-signal flexibility and chainable design, the Honeywell CP-EXPIO enhances system stability, letting you achieve finer control granularity and reduced engineering tweaks that align with operational agility in evolving industrial automation landscapes.

When evaluating I/O boosters for controller-limited stacks, the Honeywell CP-EXPIO warrants consideration for its point mix and daisy-chain ease, providing the extension reliability that amplifies capacity in EMI-challenged or space-constrained environments without compromising on configuration simplicity.

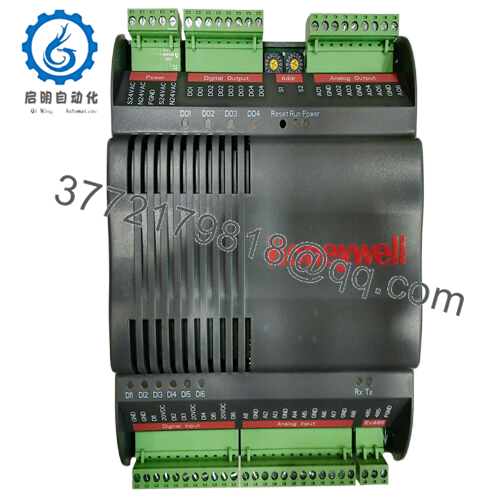

The Honeywell CP-EXPIO functions as an expansion I/O board in the peripheral layer of Honeywell’s ComfortPoint Open controller ecosystem, augmenting base units like the CPO-IPC with additional analog and digital points for sequence control, monitoring, or interfacing with field devices. It daisy-chains via RS-485 to the primary controller, occupying a DIN-rail slot where its onboard processor scans eight universal inputs (configurable for voltage, current, or resistance) and six analog outputs (0-10 V DC), plus four digital outputs via triac contacts rated for 0.5 A inductive loads, processing up to 24 points total per board. This setup enables flexible mapping through ComfortPoint Open Studio software, supporting BACnet MS/TP for network integration and diagnostics for open circuits or overrange that relay to the host controller for alarming.

- CP-EXPIO

In a typical architecture, it draws 24 V AC (±20%) from the controller’s power bus, coordinating with base I/O for hybrid signaling, such as driving VFDs from analog outputs while reading discrete feedback from sensors, and supports up to 256 points system-wide in multi-board chains. It pairs with enclosures for field mounting and complies with LonWorks for legacy ties, with LED indicators for power and comms status to aid troubleshooting. Positioned as an extender between the core controller and distributed effectors, the Honeywell CP-EXPIO optimizes the automation stack by offloading scanning to reduce host load, where its RS-485 backbone fosters linear topologies up to 1 km—cultivating a scalable I/O fabric that meshes with JACE gateways for IP overlays, upholding point fidelity across chains without introducing bottlenecks in data or power flow.

| Specification | Details |

|---|---|

| Model Number | CP-EXPIO |

| Brand | Honeywell |

| Type | Expansion I/O Board (24 Points) |

| Input Voltage | 24 V AC (±20%), 50/60 Hz |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | DIN Rail |

| Dimensions | 150 x 100 x 60 mm (approx.) |

| Weight | 0.4 kg |

| Interface/Bus | RS-485 (Daisy-Chain) |

| Compliance | CE, RoHS, BACnet MS/TP |

| Supported Protocols | BACnet MS/TP, LonWorks |

| Typical Power Draw | 15 VA |

Opting for the Honeywell CP-EXPIO equips your controller with point endurance that scales to 256 I/Os without scan degradation, quashing the capacity caps that fragment trends and delay responses in expanding loops, which in turn refines sequencing accuracy and curbs variances in metrics like flow or occupancy without auxiliary processors. This scalability shines in chained setups, where RS-485 distributes loads to prevent bottlenecks, often halving configuration time in multi-zone configs versus siloed expansions.

Diagnostic LEDs further streamline upkeep, illuminating faults for quick audits that isolate issues per board, minimizing downtime to minutes in monitored chains versus hours for unlit peers. Its DIN-rail form trims integration hurdles too—snapping into rails demands only address assignment in Open Studio, not bus reconfigs, which conserves engineering for logic tweaks over hardware hunts. Built for enclosure resilience, it withstands 5 g vibrations and 95% humidity with conformal coatings, buffering surges to sustain long-term point purity, keeping your CPO ecosystem adaptive to growth surges or ambient shifts gracefully.

In commercial chiller plants, the Honeywell CP-EXPIO extends points for pump VFDs and sensor arrays, where its mixed I/O endures humid, EMI-laced vaults to affirm critical system uptime and load balancing in continuous process control.

Light manufacturing cells deploy it for conveyor sequencing and feedback discretes, handling fast data cycles amid dusty, thermal-variable zones to synchronize high-reliability throughput.

For building automation in data centers, this board aggregates cooling valve analogs and alarm inputs, meeting high-density needs under cleanroom constraints while facilitating modular rack growth in expansive I/O panels.

CP-EXPIO-2 – Dual-chain variant for branched expansions in larger controller networks.

CPO-IPC – Compatible primary controller for up to 15 CP-EXPIO modules.

CPO-PC-6A – Alternative host with support for 16 modules in high-point setups.

CP-ODOM – Digital-only output add-on for discrete-heavy extensions.

CP-IDOM – Analog input-focused board for sensor-dense configurations.

CP-UNIOD – Universal I/O companion for hybrid analog/digital in chained boards.

ComfortPoint Open Studio – Required software for configuration and diagnostics.

Before daisy-chaining the Honeywell CP-EXPIO, confirm controller firmware at version 2.1 or later for 256-point support, and set unique addresses via DIP switches to avoid bus conflicts—duplicates inflate scan times. Verify power stability at 24 V AC with <5% ripple, and calibrate universal inputs with a precision source in staging to match your signal types, adding termination resistors if chains exceed 500 m.

Ongoing care includes quarterly terminal inspections for corrosion in humid enclosures, wiping with isopropyl to preserve contact integrity. Monitor RS-485 LEDs monthly for comms drops, logging variances over 2% for cable checks. Perform an annual full-chain test by simulating loads across all 24 points to validate scan under 100 ms, and update firmware via Honeywell’s portal for enhanced BACnet features. This measured routine keeps extensions humming without derailing operations, supporting your team’s focus on optimization.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626