Description

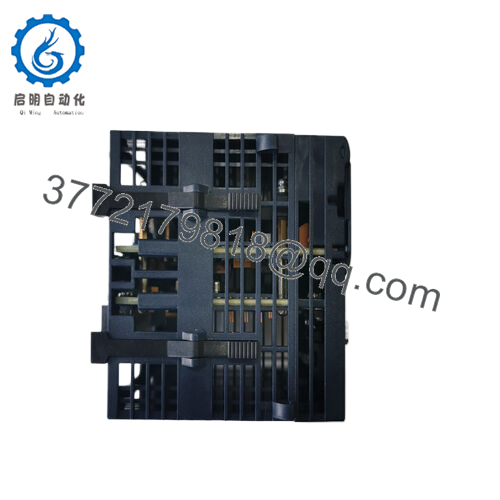

Product Model: IC697CHS770D

Product Brand: GE Fanuc (Emerson)

Product Series: Series 90-70 Redundant Rack Assembly

Product Features:

• Dual redundant rear-mount rack for GE Fanuc Series 90-70 PLC systems, enabling high-availability configurations with dual systems per chassis.

• Provides standardized backplane interconnection, power distribution, and module mounting for CPUs, I/O, and communication modules.

• Hot-swap support and modular flexibility facilitate maintenance and system expansion.

• Designed for rugged industrial environments requiring scalable control system reliability.

- IC697CHS770D

Technical Specifications Table

| Specification | Details |

|---|---|

| Model Number | IC697CHS770D |

| Brand | GE Fanuc (Emerson) |

| Product Type | Dual Redundant Rack Assembly |

| PLC Series | Series 90-70 |

| Mounting Style | Rear mount |

| System Support | Dual independent PLC systems |

| Slots per System | Multiple (dual banks, typically 6 + power requires) |

| Backplane Power Distribution | +5 VDC and internal distribution |

| Redundancy | Dual power feeds and dual module paths |

| Hot-Swap Capability | Yes (module level) |

| Compatibility | Supports IC697 Series modules and IC687 (VME) modules |

| Industrial Construction | Rigid steel frame, industrial backplane |

| Operating Temp Range | Typical industrial (0°C to 60°C) |

| Installation | Rear panel, deep enclosure required |

Product Role & System Fit

The IC697CHS770D serves as a dual redundant rear-mount rack chassis within the GE Fanuc Series 90-70 programmable logic controller (PLC) ecosystem. In industrial automation, the rack is not a controller itself, but it is the structural and electrical heart of a distributed control system. It provides the physical backplane and slots needed to house CPU modules, I/O interfaces, communication processors, and specialty modules, while also enabling fault-tolerant, dual-system deployment.

Redundancy — which is facilitated by the dual power and dual slot sections — is a defining characteristic of the IC697CHS770D. In mission-critical applications such as power plants, automotive manufacturing lines, chemical processing installations, and infrastructure management systems, continuous operation is paramount. A redundant rack allows two parallel PLC systems to operate within the same chassis so that if one system fails, the second can seamlessly take over control functions without loss of data or stoppage of the process.

Unlike standard non-redundant racks that only contain a single set of slots for modules and power supplies, this dual configuration enables redundant CPUs, redundant power inputs, and independent backplane paths. In practice, this means engineers can design high-availability architectures where software logic and I/O processes continue to run even when a subsystem encounters a fault, a rare but critical requirement in sectors like automotive body-in-white fabrication or continuous refining operations.

The chassis itself is often mounted in a control panel or enclosure, usually occupying a rear mounting position because of its deeper footprint and cable routing requirements. Engineers planning a Series 90-70 installation will select the IC697CHS770D early in the hardware design phase because it dictates rack power planning, module layout, bus connectivity, and redundancy strategy.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626