Description

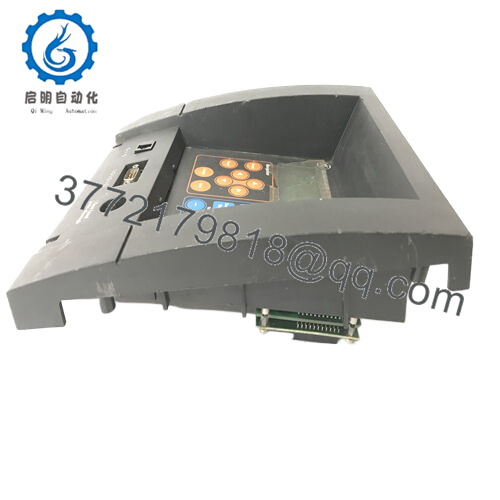

Product Model: IC754VSL06MTD

Product Brand: GE (General Electric / GE Fanuc)

Product Series: QuickPanel View HMI

Product Features:

• Robust 6-inch monochrome resistive touchscreen for operator control.

• Windows CE-NET operating platform compatible with Proficy Machine Edition.

• Multiple communication ports including Ethernet, RS-232/RS-485, USB.

• Compact, low-power design ideal for space-constrained control panels.

Technical Specifications Table

| Specification | Detail |

|---|---|

| Model | IC754VSL06MTD |

| Display Size | 6 inches |

| Display Type | Monochrome resistive touchscreen |

| Resolution | 320 × 240 pixels |

| Processor | Intel XScale PXA255 (~300 MHz) |

| Operating System | Windows CE.NET |

| Memory | DRAM 32 MB (approx), Flash storage |

| Communication Ports | Ethernet 10/100, RS-232, RS-485, USB 1.1 |

| Expansion Slot | Type II CompactFlash |

| Input Voltage | 12–30 VDC |

| Power Consumption | ~15W max |

| Operating Temp | 0–50°C |

| Weight | ~4.56 kg |

| Mounting | Panel mount |

- IC754VSL06MTD

Product Role and System Fit Within Automation Architectures

The IC754VSL06MTD functions as a Human-Machine Interface (HMI) within industrial control systems, bridging the logic and sensing capabilities of PLCs with the actionable input and real-time feedback operators require. In practical terms, this module acts as the display and control head for legacy PLC systems — particularly those using GE 90-Series, VersaMax, or early PACSystems architectures.

Compact operator terminals like the IC754VSL06MTD play a dual role: they visually present crucial process variables and allow personnel to execute commands such as start/stop cycles, setpoint changes, or alarm acknowledgements. Their placement matters — mounted directly on machine guard doors or central panels — where touch interaction must be both immediate and intuitive.

It fits naturally into existing industrial Ethernet and serial communications networks, supporting both 10/100 Mbps Ethernet and traditional RS-232/485 links. Such connectivity ensures legacy PLCs without modern Ethernet/IP stacks can still interface with field-level operator interfaces without the need for expensive gateways or network converters.

Another aspect of system fit involves software compatibility. The device runs Windows CE.NET and works with GE’s Proficy Machine Edition configuration environment, allowing automation teams to port existing visualization screens or develop new operator graphics without learning entirely new design tools.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626