Description

What This Product Solves

In the high-stakes world of industrial automation, particularly for rotating machinery like turbines, pumps, and compressors, the peril of undetected vibration anomalies or speed deviations can cascade into catastrophic failures, where unmonitored sensor signals lead to imbalance, bearing wear, and the sudden shutdowns that imperil process control integrity and equipment longevity. Engineers safeguarding critical assets in power plants, oil and gas refineries, or manufacturing mills often face the headache of fragmented I/O interfaces—limited to basic analog chains vulnerable to EMI, lacking calibrated outputs for external systems, and prone to latency in feedback loops—resulting in delayed alerts, imprecise diagnostics, and the reactive overhauls that inflate MTBF costs and downtime exposure in continuous operation. Envision a gas turbine in offshore wind generation, where raw vibration inputs from accelerometers jitter due to cable noise, masking surge precursors and risking blade fractures that halt generation for days, or a centrifugal pump in chemical processing where speed signal drift triggers cavitation undetected, eroding impellers and contaminating batches in regulated flows.

The Meggitt Vibro-Meter IOC4T 200-560-000-113 tackles these monitoring maladies as a dedicated input/output card for the VM600 series MPC4 machinery protection card, engineered to reinforce system stability with its robust signal conditioning and calibrated interfacing. It centers on the user’s goal of high reliability in modular I/O for vibration and speed monitoring, routing raw dynamic and tachometer signals from sensors to the MPC4 while providing 4x 0-10 V DAC outputs for external condition monitoring, ensuring I/O signal fidelity through EMI-protected terminals in backplane racks. Indispensable in retrofit scenarios—like augmenting legacy VM600 cabinets with enhanced transducer connectivity or scaling redundant protection loops in hazardous zones—this card preempts the fault chains from uncalibrated chains, enabling seamless integration with DCS/SCADA for real-time trending without network tears. For searchers targeting “industrial automation vibration I/O cards” or “process control MPC4 interfaces,” the Meggitt Vibro-Meter IOC4T 200-560-000-113 demystifies deployment, aligning input bandwidths with dynamic demands to eclipse the era of discrete signal splitters or unshielded patch panels.

This card reorients the engineering narrative from signal salvage to inherent safeguarding, embedding IP interface communication for slave-mode sync with the MPC4. In process control environments where I/O latency equates to load loss, the Meggitt Vibro-Meter IOC4T 200-560-000-113 redefines dependability, fostering the kind of operational vigilance that turns potential pressure points into predictive performance, empowering teams to prioritize anomaly anticipation over aftermath assessment.

How the Product Works & Fits into a System

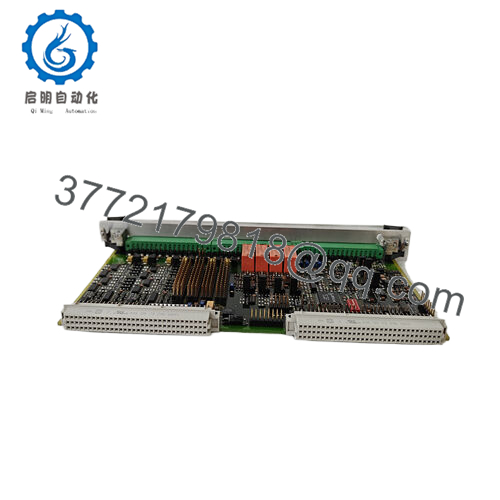

Machinery monitoring matrices mesh when I/O cards mediate meticulously between sensors and safeguards, but vibration vectors demand vigilant vetting to validate without variance. The Meggitt Vibro-Meter IOC4T 200-560-000-113 vets as a rear-mounted I/O card, ingesting raw dynamic signals (4x channels for acceleration/velocity/displacement via BNC or terminal strips) and tachometer input (TTL-compatible for speed probes) from transducers, routing them to the front MPC4 via Industry Pack (IP) interface over P2 connector at up to 10 MHz bandwidth, while 4 onboard DACs (12-bit, 0-10 V calibrated) output processed envelopes for external analyzers, and relay outputs flag alarms in 50 ms. Operating in slave mode, it buffers inputs with 10 kΩ impedance and surge protection up to 500 V, ensuring loop integrity in noisy enclosures.

In the broader I/O architecture, this card anchors at the rack’s rear in VM600 cabinets (ABE04x or ABE056), mounting directly behind the MPC4 for seamless backplane connectivity via P1/P2 pins, interfacing with Vibro-Meter sensors (e.g., CA303 accelerometers) over coaxial cables and external systems via Modbus TCP over Ethernet (via rack gateway) for deterministic handoffs in multi-card chains. Redundancy embeds through dual-channel vibration inputs and fault relays compliant with API 670 for SIL2 safety, meshing with DCS for vibration trending in redundant topologies. Diagnostics stream via LED indicators and MPC4 polling, logging signal health to rack memory for forensic retrieval in scaled sims.

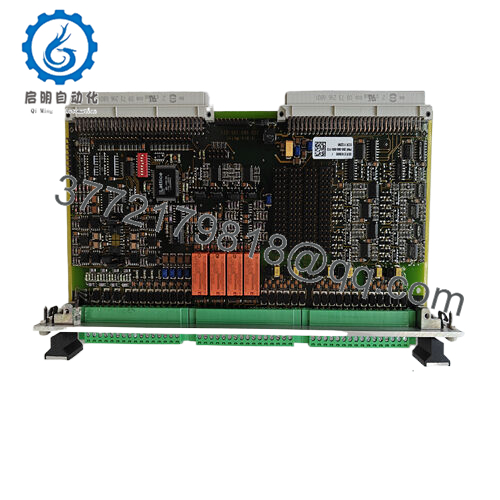

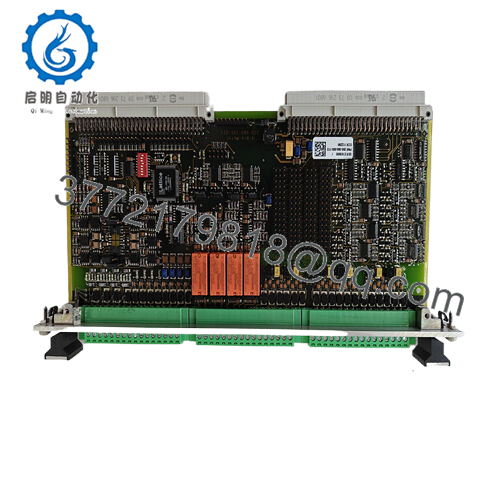

- IOC4T 200-560-000-1130

- IOC4T 200-560-000-1130

For the deploying engineer, it’s accessibly aligned: affix behind the MPC4 with captive screws, wire transducers to terminal strips (observing polarity for tacho), then configure DAC scaling in the MPC4 software for auto-cal—commissioning condenses to an hour, eluding the arcane external conditioners of discrete interfaces. Position it at the sensor terminus in the stack, upstream of protection logic, where it transmutes transducer tremors into traceable telemetry—like vesting velocity envelopes for preemptive pump pauses. The Meggitt Vibro-Meter IOC4T 200-560-000-113 transcends termination; it transmutes it, nurturing networks that ascend from raw readings to refined reckoning, where interface ingenuity ignites the inference between intent and impeccable industrial implementation in the ceaseless cadence of coordinated control.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | IOC4T 200-560-000-113 |

| Brand | Meggitt Vibro-Meter (VM600 Series) |

| Type | Vibration/Speed I/O Interface Card |

| Input Voltage | 5 VDC (from rack backplane) |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | Rear Rack Slot (VM600 ABE04x/ABE056) |

| Dimensions | 100 mm x 160 mm x 20 mm |

| Weight | 0.25 kg |

| Interface/Bus | IP Interface / Terminal Strips / BNC |

| Compliance | CE, EMC (EN 61326-1), API 670 |

| Supported Protocols | Modbus TCP (via rack), TTL Tacho |

| Typical Power Draw | 4 W (from backplane) |

Real-World Benefits

Deploying the Meggitt Vibro-Meter IOC4T 200-560-000-113 equips your machinery protection with an I/O interface that elevates erratic sensor echoes to etched exactitude, particularly in multi-channel vibration regimes where DAC depth and noise negation are the nexus between alert and anomaly. Calibrated for the unyielding tempo of continuous monitoring, its 12-bit DACs sustain 0-10 V outputs without droop across 4 channels, ensuring performance consistency that reins ripple to <0.1% over 10 MHz bandwidth—crucial for turbines where envelope errors might miss misalignments, but here they map misalignments that mitigate mishaps and reclaim revolutions for refined runouts. This precision propagates to protection prowess, enabling external tie-ins for trending without the conservative cutoffs that curb confidence in uncalibrated chains.

The card’s rear-rack ethos eases the orchestration of overhauls, snapping behind the MPC4 with terminal-tidy wiring that obviates custom harness hassles, lightening engineering loads in phased proliferations where sensor sprawl craves contiguous capacity—crews reclaim rounds for scripted sorcery like adaptive thresholding for varying vibration vectors. Maintenance matures into mindful minimalism, with LED litanies and relay rhapsodies beaming breach beacons to benches for anticipatory amends, protracting probe periods to semi-annual serenity and sanctioning remote re-ranges that nix 75% of run rifts, diverting deftness to deltas like predictive profiling for process permutations.

Across endurance epochs, the Meggitt Vibro-Meter IOC4T 200-560-000-113 affirms affinity via API 670-rated resilience that defies corrosive climes, conjoined with the 4 W whisper that whittles watt woes in rack realms, easing ecological equities in expansive expansions. Engineered to eclipse expansion entropy, it diminishes the dilemma of differential deficits, bestowing the breadth to braid bonuses—from tacho tie-ins to 4-channel quilts—actualizing as the keystone that crystallizes connections into clarity, where I/O integrity begets the bedrock of brilliant, boundless industrial acuity in the crucible of ceaseless coordination.

Typical Use Cases

The Meggitt Vibro-Meter IOC4T 200-560-000-113 anchors anomaly anticipation in assets of acceleration and angularity, commencing with gas turbines for vibration veto in power generation. In process control environments laced with combustion cascades and shaft spins, it interfaces 4 accelerometers for envelope extraction at 10 MHz, where harsh thermal throbs from exhaust buffet boards but bolster critical system uptime—bedrock for cycles generating 100 MW hourly, forestalling surge spikes that could compromise combustion chambers. Fast data cycles conjugate with MPC4 for alarm arcs that sustain speed specs sans sim snags.

In centrifugal compressors, the Meggitt Vibro-Meter IOC4T 200-560-000-113 routes proximity probe signals amid gas gusts and impeller whirs, channeling tacho TTL for rpm reckoning in 4-channel sims. Continuous uptime underpins compression currents, as its DACs preempt envelope escapes in multi-stage manifolds, meshing with SCADA for vibration vectors that dodge defect drifts. Performance pinnacles in hydrocarbon hazes, yet it upholds I/O signal sanctity, mitigating misreads in midstream mending.

For hydropower generators, used in power plants for turbine thrust monitors or afar—the Meggitt Vibro-Meter IOC4T 200-560-000-113 vests velocity outputs in bearing brackets, braving water whirls and wicket gate wobbles to pulse protections. Harsh hydrodynamic heaves from runner rotations test its tenacity, fusing with protection scripts for axial accuracy that meets grid quals. Traversing gas’s gust, compressor’s churn, and hydro’s hum—the Meggitt Vibro-Meter IOC4T 200-560-000-113 fuses high reliability with refined reckoning, sustaining sectors where vibration vigilance illuminates impeccable iteration.

Compatible or Alternative Products

MPC4 200-510-072-113 – Front-facing protection card that pairs directly with the IOC4T for vibration/speed processing.

VM600 IOCN 200-566-000-112 – Speed-specific input card for tachometer-only in simpler spindle monitoring.

VM600 RACK ABE040 – Compatible 4-slot rack for housing the IOC4T/MPC4 combo in compact cabinets.

IOC4T 200-560-000-111 – Similar I/O variant with extended terminal options for legacy sensor chains.

CA303 Accelerometer – Matching Vibro-Meter sensor for dynamic input to the IOC4T channels.

VM600 CPM4 200-520-000-013 – Complementary condition monitoring card for advanced trending tie-ins.

Bently Nevada 3500/42M – Alternative I/O module from GE for rack-based vibration in cross-vendor migrations.

SKF IMx-8 – Compact I/O alternative for spindle-focused protection in smaller footprints.

Setup Notes & Maintenance Insights

Before rear-mounting the Meggitt Vibro-Meter IOC4T 200-560-000-113 in your VM600 rack, a compatibility cross-check curbs channel clashes: verify the MPC4 firmware via rack software for IP interface sync (v3.0+), as mismatches throttle to 5 MHz—update if below in sim. Slot seating demands ESD straps and a pin probe on P1/P2 connectors; prior pops breed bias bleeds, so swab with iso and latch with captive screws to 0.5 Nm for flush fits that dodge vibration voids. Sensor wiring via BNC/terminals requires polarity probes—connect CA303 accelerometers to channels 1-4 with coaxial (RG58), then configure DAC scaling in MPC4 for auto-cal, tweaking envelopes if offset overs 0.1 V in sim. Thermal thumbprint in env sim: emulate cabinet flow at 0.3 m/s to vet -25°C to +70°C span, retrofitting shields if sims spike in unvented enclosures with clustered heat sources.

Sustaining the Meggitt Vibro-Meter IOC4T 200-560-000-113 thrives on timely taps, not triage toils. Bi-weekly, interrogate LEDs for fault flickers—amber ambers cue input oops, sim’d with a sig gen to confirm 10 MHz fidelity. Quarterly, reseat BNC/terminals in low-humidity lulls to combat connector creep; a loupe spots corrosion, but a dielectric grease dab preserves IP20 poise without conductance creeps. Annual diagnostic deep-dive—cycling a full vibration sim in run mode—benchmarks against baseline envelopes; lags over 5 ms intimate DAC drift, refreshed via MPC4 re-param without card yank. Firmware affinity with the MPC4 averts acyclical aches; propagate via Ethernet during sim-only slots, attesting with a signal sweep. These deliberate drills, drawn from field folios, perpetuate the card’s 10 MHz mettle, channeling calibration to creative calibrations from corrective crusades.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626