Description

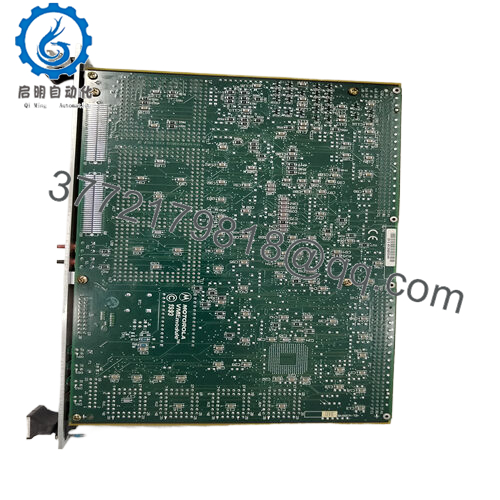

In industrial automation and embedded control systems, where VMEbus architectures must deliver robust computational power to manage real-time tasks without buckling under environmental stressors or legacy integration constraints, engineers often face challenges with processors that lag in throughput or demand extensive rewiring for upgrades. The Motorola MVME187 tackles this as a high-performance single-board computer (SBC) from the VME series, powered by a 25 MHz MC68040 processor with floating-point capabilities to drive deterministic control in demanding applications. Picture a petrochemical plant coordinating valve sequencing or an aerospace test rig processing telemetry streams—here, bus contention or memory bottlenecks can disrupt cycles, inflate latency, or trigger faults that derail process control. This module is critical in such high-reliability scenarios, where its enhanced I/O signal handling and VMEbus mastery ensure system stability across dense peripheral arrays, even in vibration-heavy or thermally volatile setups. It promotes seamless data flow for tasks like PID loop execution, mitigating risks from EMI or power transients common in industrial environments.

The Motorola MVME187 excels in modernizing aging VME racks, where modular integration allows drop-in replacement of 68020/30 boards without chassis redesigns. Its 4 MB SRAM and dual-port DRAM counter the signal unreliability that plagues older SBCs in noisy control rooms, while onboard SCSI and Ethernet bolster connectivity for SCADA or DCS tie-ins. At its core, it supports engineers’ goals for multitasking under RTOS like VxWorks, slashing debug cycles during commissioning. For system architects or retrofit specialists seeking extended lifecycle in rugged automation, the Motorola MVME187 delivers a high-reliability cornerstone that transforms legacy limitations into scalable performance, ensuring every interrupt fuels precise process control.

The Motorola MVME187 anchors the computational core in VMEbus ecosystems, wielding the MC68040’s 32-bit architecture to manage A32/D32 transactions across the VME P1/P2 backplane, supporting up to 7 interrupt levels for real-time prioritization. It integrates 4 MB SRAM, 4-16 MB DRAM, and 512 KB EPROM for boot and application storage, processing inputs from two RS-232/422 serial ports, a SCSI bus, and an Ethernet AUI for networked HMI or data logging. In a typical 6U VME crate, it draws +5 V/+12 V from the bus, dispatching DMA to peripherals like A/D converters or motor controllers while arbitrating via onboard VMEchip2 for master/slave roles. This positions it mid-stack—above field I/O but below supervisory kernels—with timers enforcing watchdog resets to prevent hangs in safety-critical loops.

Its interaction strengths include configurable boot ROMs for network or local loads, with diagnostics streamed via serial to debug consoles, easing integration into SCADA through Ethernet or SCSI for mass storage. Redundancy unfolds via dual-board setups in fault-tolerant chassis, and LED indicators flag bus errors or cache misses for quick triage. The Motorola MVME187’s analog-centric design avoids protocol bloat, letting engineers tune interrupt vectors for low-latency tasks in process control domains—from robotic sequencing to grid monitoring—where it harmonizes with legacy VME I/O, minimizing conversion overheads while sustaining deterministic cycles.

- MVME187

| Specification | Details |

|---|---|

| Model Number | MVME187 |

| Brand | Motorola |

| Type | VMEbus SBC Module |

| Input Voltage | +5 Vdc / +12 Vdc (bus) |

| Operating Temp Range | 0°C to +70°C |

| Mounting Style | VME 6U Eurocard |

| Dimensions | 233 x 160 mm |

| Weight | 0.5 kg |

| Interface/Bus | VMEbus (A32/D32) |

| Compliance | IEEE 1014, CE |

| Supported Protocols | RS-232/422, SCSI, Ethernet |

| Typical Power Draw | 15 W |

Choosing the Motorola MVME187 embeds reliability that endures rack stressors, its conformal-coated PCB and bus buffers preserving cache coherence through EMI bursts or thermal spikes to avert data corruptions that stall sequences—yielding MTBF gains and confidence in multi-year deployments for resource-tight industrial teams. Its integration ease shines, with pin-compatible VME slots enabling live swaps via soft resets that dodge power faults, shrinking upgrade windows from days to hours and easing engineering loads in OEM retrofits where bus universality skips rewiring.

Maintenance pivots to foresight; parity checks and serial logs expose ECC errors for spot fixes, syncing with semiannual crate audits to verify bus timings without halting operations. The Motorola MVME187 enhances long-term performance by supporting FPU-intensive tasks like signal filtering, boosting throughput by 20-30% in control loops and aligning with legacy safety standards. This scalability supports growth—add PMC carriers or SCSI drives without re-architecting—while its Ethernet backbone enables remote diagnostics, making it a strategic choice for automation stewards navigating real-time process control across aging VME infrastructures.

The Motorola MVME187 drives petrochemical DCS, where it processes valve position feedback for flow regulation, delivering high-reliability I/O over VMEbus in corrosive, vibration-prone process control settings with steadfast interrupt precision. In aerospace ground stations, it aggregates radar data for real-time analysis, enduring thermal swings while ensuring critical system uptime via robust DMA in EMI-heavy bays. For rail signaling systems, it orchestrates interlocking logic, providing reliable serial polling against dust ingress to maintain uptime under stringent safety certifications.

MVME167 – 68030-based predecessor for cost-sensitive legacy upgrades

MVME197LE – Enhanced Ethernet model for networked SCADA emphasis

MVME374-1 – 68020 variant for lighter-throughput VME applications

MVME5100 – PowerPC upgrade path for modernized VME64x transitions

MVME162PA – IP module companion for expanded I/O mezzanines

MVME2700 – 750-class successor with higher clock for compute-intensive tasks

MVME147 – SCSI-heavy alternative for storage-centric control nodes

MVME188 – Dual-processor edition for parallel processing in dense racks

Before deploying the Motorola MVME187, ensure VME crate power budgets stay below 80 A total—overloads heat junctions past 80°C—and verify P2 pin continuity for full A32/D32 support, as partial populations drop to A16 modes, choking DMA. Fuse +5 V/+12 V rails at 4 A/1 A to curb inrush spikes over 20 W, and burn EPROMs with site-specific boot vectors via Motorola’s BDM utility to prevent init loops. For Ethernet ties, sync PHY settings at 10Base-T defaults, as autonegotiation missteps spawn packet drops.

Maintenance hinges on quarterly LED checks for bus arbitration or DRAM parity flags, paired with backplane pin cleans for oxide films in humid racks—use ethanol-soaked swabs to avoid corrosion. Annual BDM scans validate EPROM integrity, queuing re-burns during downtimes, and in multi-board setups, rotate interrupt priorities semiannually to balance bus wear. These field-honed practices sustain the Motorola MVME187’s vigor with minimal disruption, drawn from decades of VME deployments.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626