Description

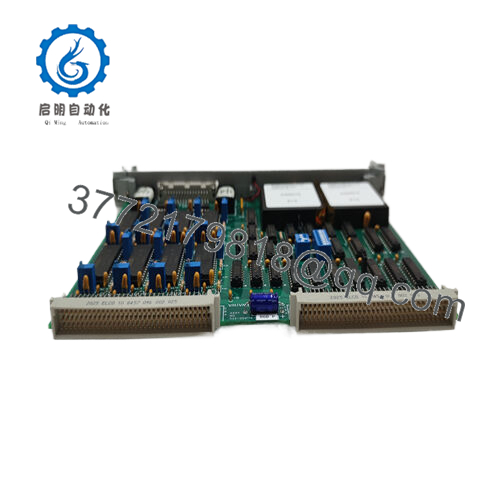

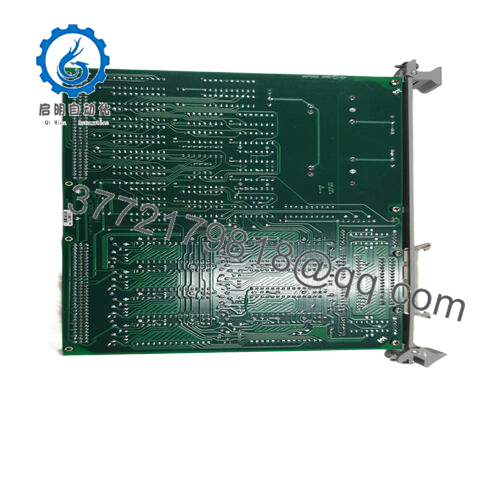

Product Model: DS6815PCDP1B1A

Product Brand: GE Fanuc / GE Automation

Product Series: Series 90-30 PLC Platform

Product Features:

- High-speed, deterministic control optimized for complex industrial processes

- Seamless integration with Series 90-30 I/O, communication, and specialty modules

- Rugged design built for harsh manufacturing and process environments

- Supports ladder logic, structured text, and advanced programming languages

Technical Specifications Table

| Specification | Detail |

|---|---|

| Model | DS6815PCDP1B1A |

| Brand | GE Fanuc / GE Automation |

| Series | Series 90-30 |

| CPU Type | High-Performance Programmable Controller |

| I/O Capacity | Supports up to 256 I/O points |

| Memory | Battery-backed user memory for program and data retention |

| Communication | Serial RS-232/RS-485; optional Ethernet via adapters |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -20°C to 70°C (-4°F to 158°F) |

| Shock & Vibration | IEC 60068-2 series compliant |

| Power Requirements | 5V DC regulated supply |

| Mounting | DIN rail or panel mount |

| Programming Languages | Ladder, structured text, function block |

- DS6815PCDP1B1A

Technical Features & Benefits

The DS6815PCDP1B1A combines processing power with industrial resiliency. Its high-speed CPU ensures deterministic logic execution, a prerequisite for coordinated machine operations where timing consistency is critical. In high-speed packaging lines or automated test cells, this predictability helps eliminate timing drift and ensures consistent quality.

Rugged construction is a core benefit. Designed for environments with vibration, temperature swings, and electrical noise, the module resists conditions that cause failures in lower-grade controllers. This robustness yields long service intervals and lower total cost of ownership.

Another standout feature is the controller’s integration with GE’s automation software ecosystem. Engineers can use familiar programming tools to build, simulate, debug, and monitor control logic. Diagnostics tools provide visibility into system health, helping identify and isolate issues before they escalate into production losses.

Communication flexibility is also a strength. While basic serial connections serve many legacy applications, optional Ethernet adapters expand connectivity — enabling data exchange with SCADA, HMIs, and remote diagnostics. Facilities pursuing digital transformation appreciate this adaptability because it permits phased upgrades without system redesign.

Finally, efficient energy use completes the controller’s feature set. The DS6815PCDP1B1A delivers high-end performance without excessive power draw, an important consideration for plants managing energy budgets or pursuing sustainability metrics.

Related Models

- DS6815PCDP1B1B – Variant with extended communication ports.

- DS6815PCDP2B1A – Supports expanded I/O capacity for larger installations.

- DS6815PCDP1C1A – Enhanced environmental tolerance option.

- DS6815PCDP1B2A – Additional memory for more complex logic storage.

- DS6815PCDP1D1A – Includes advanced serial redundancy features.

- DS6815PCDP1B1C – Compact version for space-constrained control cabinets.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626