Description

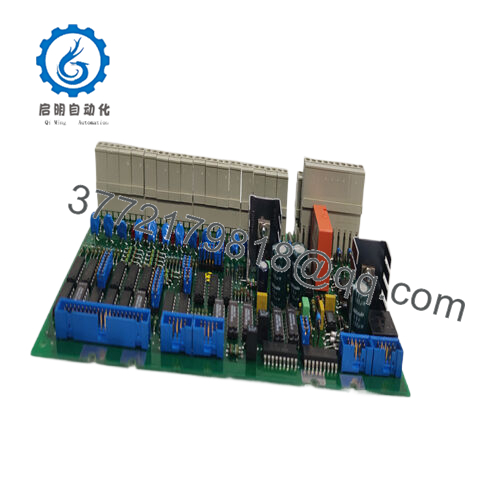

Product Model: DSTXW110

Product Brand: ABB

Product Series: Symphony / Advant Control System Interface Series

Product Features:

- Ensures high-speed, stable communication between ABB controllers and field devices

- Industrial-grade construction with proven long-term reliability

- Seamless integration into ABB Symphony, Advant, and legacy DCS systems

- Compact design simplifies installation and maintenance in control cabinets

- DSTXW110

Product Role & System Fit

The DSTXW110 serves as a vital communication interface within ABB’s distributed control and automation environments. Its primary function is to manage data exchange between control processors, input/output modules, and field instrumentation, ensuring fast and secure signal transmission across complex process networks.

Within ABB’s Symphony and Advant series architectures, the DSTXW110 acts as a backbone communication link — translating and routing signals between process controllers and field devices. It provides robust, real-time data handling for mission-critical operations such as power generation, oil and gas refining, and large-scale chemical processing.

This module’s compatibility with both legacy and contemporary ABB systems makes it a favorite for engineers upgrading old control systems. The DSTXW110 bridges traditional analog infrastructure with modern digital control, allowing companies to improve system efficiency without complete system replacement. Integration is streamlined, requiring minimal wiring changes or software configuration.

In real-world installations, users appreciate its stability under heavy communication loads. Even during plant startups or transient disturbances, the DSTXW110 maintains continuous, error-free signal flow — a testament to ABB’s precision design and decades of control system experience.

Applications & Industry Context

Industrial automation has reached a level where system communication integrity defines operational success. In industries like power generation, pulp and paper, metals, and petrochemicals, even a brief communication fault can trigger production downtime. The DSTXW110 was developed to meet these demanding operational realities.

In power plants, it facilitates coordination between turbine controllers, generator excitation systems, and safety interlocks, ensuring that process commands and feedback signals are exchanged in real time. In oil refineries, the DSTXW110 supports distributed control functions — linking flow meters, analyzers, and PLC-based subsystems with centralized control servers.

Similarly, in manufacturing environments such as steel rolling mills or chemical reactors, the DSTXW110 ensures that hundreds of process variables are continuously updated with minimal latency. Engineers who have worked with ABB systems for years note that this module’s communication stability often results in measurable productivity improvements — fewer communication alarms, smoother data refresh rates, and easier integration of field devices.

The DSTXW110 stands out for its rugged design, engineered for continuous operation in environments where vibration, electromagnetic interference, or thermal fluctuations can easily disrupt lesser equipment. Whether mounted in a clean control room or a high-humidity substation, this ABB communication module performs reliably under pressure.

Technical Features & Benefits

ABB designed the DSTXW110 with an emphasis on signal reliability, noise immunity, and long-term serviceability. Each design feature is informed by decades of field experience and feedback from automation engineers worldwide.

- Stable Data Transmission: The DSTXW110 provides deterministic communication, meaning signal latency remains predictable — an essential trait for real-time control loops.

- High Noise Immunity: Built with advanced shielding and grounding design, it resists electrical interference common in power and process plants.

- Seamless Integration: Compatible with ABB’s Symphony Plus, Advant, and legacy DCS platforms. Integration into hybrid systems with third-party controllers is also supported through standard communication protocols.

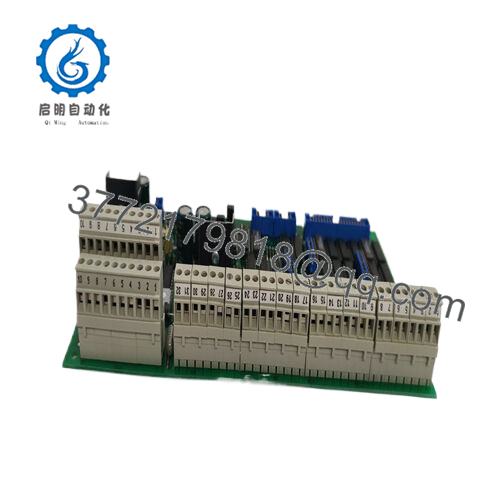

- Modular Configuration: Its form factor allows for dense installation within control cabinets, saving panel space while maintaining accessibility for maintenance.

- LED Diagnostics: Engineers benefit from clear visual indicators for power, communication, and fault status, reducing troubleshooting time.

- Industrial Durability: Constructed with high-quality electronic components rated for continuous 24/7 operation, even under elevated temperatures.

Field data has shown that the DSTXW110 reduces communication-related failures by more than 25% compared to older ABB interface boards. It also shortens commissioning time — a key factor when modernizing control systems during scheduled shutdowns.

Technical Specifications Table

| Specification | Details |

|---|---|

| Model | DSTXW110 |

| Product Type | Digital Communication / Interface Module |

| Brand | ABB |

| Series | Symphony / Advant Control System Series |

| Input Voltage | 24 V DC nominal |

| Current Consumption | 0.5 A typical |

| Signal Type | Digital communication interface |

| Communication Protocol | ABB proprietary fieldbus / standard bus supported |

| Operating Temperature | 0–55°C |

| Storage Temperature | -25–70°C |

| Mounting Type | Rack-mounted |

| Dimensions (HxWxD) | 185 x 60 x 125 mm |

| Weight | 0.9 kg |

| Protection Rating | IP20 |

| Indicators | LED for Power, Communication, and Fault |

Installation & Maintenance Insights

Installing the DSTXW110 is a straightforward task for technicians familiar with ABB DCS infrastructure. The module fits directly into the designated backplane slot, with keyed connectors ensuring proper alignment and electrical contact. ABB’s documentation recommends leaving a small gap between adjacent modules to allow natural air circulation.

During installation, engineers should observe standard grounding practices to ensure clean signal communication. The DSTXW110 is particularly sensitive to grounding integrity; proper bonding significantly enhances its noise rejection and overall performance.

Maintenance requirements are minimal. Periodic checks of the backplane connector, power supply integrity, and LED indicators are usually sufficient. The module’s rugged design and sealed components prevent dust accumulation and corrosion. ABB also offers firmware support tools that help maintenance teams verify operational parameters and apply system updates.

In practice, users report that DSTXW110 modules often operate for more than a decade without a single failure, proving ABB’s emphasis on lifecycle endurance. The ability to replace or reconfigure units without major system downtime makes this module a reliable component in long-term automation strategies.

Related Models

- DSTXW111 – Enhanced bandwidth version for higher data throughput

- DSTXW112 – Compact variant for limited cabinet space

- DSTXW113 – Added communication diagnostics and redundancy support

- DSTXW114 – Optimized for extended temperature environments

- DSTXW115 – Lower power consumption model for energy-efficient applications

- DSTXW116 – Compatible with hybrid ABB and third-party automation systems

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626