Description

The Foxboro FEM100 P0973CA is a Fieldbus Expansion Module (FEM) designed to increase the capacity and connectivity of modular Field Control Processors (FCP270) within Foxboro’s I/A Series distributed control systems. Its primary use is to provide four expanded Fieldbus segments, allowing the system to support a higher number of 200 Series Fieldbus Modules (FBMs), effectively expanding the system’s I/O without compromising performance. This capability is essential for large-scale industrial automation applications such as chemical plants, power generation, and water treatment facilities, where control and monitoring of numerous process variables require scalable and robust communication infrastructure.

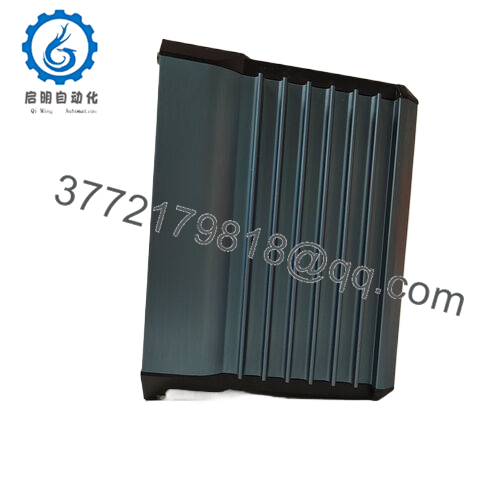

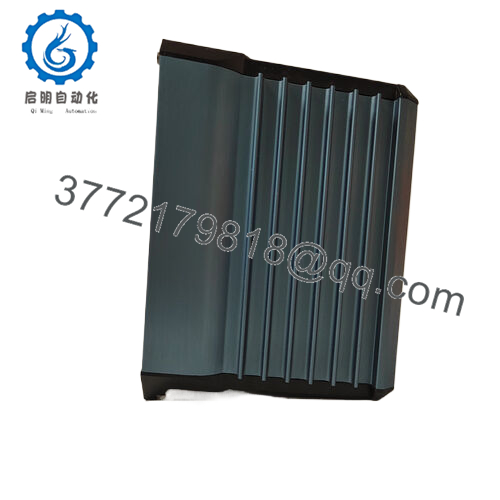

The module supports the 2 Mbps HDLC (High-Level Data Link Control) module Fieldbus protocol to efficiently manage communication between the FCP270 controller and connected FBMs. Each expanded Fieldbus segment can handle up to 32 FBMs, meaning one FEM100 P0973CA module can support up to 128 devices, providing significant system scalability. REDUNDANCY options in the module are designed to ensure communication integrity by minimizing interruptions through multiple channels. The FEM100 P0973CA mounts on DIN rails using two-slot or four-slot expansion baseplates, suitable for vertical mounting in control cabinets. Its rugged aluminum enclosure offers environmental protection to meet harsh industrial conditions classified as Class G3 by ISA S71.04 standards, making it reliable in contaminated or challenging environments.

Key technical specifications reveal that the module operates on a 21 to 26 V dc power supply with a maximum power consumption of 2.2 watts, reflecting its low energy footprint. It functions reliably within an operating temperature range of -20 to +70 °C and supports relative humidity levels from 5% to 95% (non-condensing). The module has dimensions of 99 mm height, 44.6 mm width, and 105 mm depth, weighing approximately 0.6 kg. Visual LED indicators on the front panel provide real-time status information for diagnostics and maintenance purposes, enhancing operational insight and ease of troubleshooting.

| Parameter | Value |

|---|---|

| Model | Foxboro FEM100 P0973CA |

| Brand | Foxboro |

| Product Type | Fieldbus Expansion Module |

| Communication Protocol | 2 Mbps HDLC Module Fieldbus |

| Number of Fieldbuses | 4 Expanded Fieldbus Segments |

| Devices Supported | Up to 128 FBMs total (32 per Fieldbus) |

| Power Supply | 21 to 26 V dc |

| Power Consumption | 2.2 W max |

| Operating Temperature | -20 to +70 °C |

| Relative Humidity | 5 to 95% non-condensing |

| Environmental Rating | Class G3 Harsh (ISA S71.04) |

| Mounting | DIN rail, Two-slot or Four-slot Expansion Baseplates |

| Dimensions (H x W x D) | 99 mm x 44.6 mm x 105 mm |

| Weight | Approx. 0.6 kg |

| Certifications | EMC, UL, RoHS compliant |

| Diagnostic Indicators | LED status indicators |

- FEM100 P0973CA

- FEM100 P0973CA

Related Modules or Compatible Units

Foxboro FCP270 – Field Control Processor module interfacing with the FEM100 for expanded system control.

Foxboro FBM100 – Fieldbus modules controlled via the FEM100 expansion segments.

Foxboro P0973CG – Two-slot Expansion Baseplate compatible with FEM100.

Foxboro P0973CN – Four-slot Expansion Baseplate for larger system configurations.

Foxboro FCM10E – Communication Interface Module supporting the 200 Series modules.

Foxboro FBM230 – Serial communication module complementing bus extension capabilities.

Installation Notes & Maintenance Best Practices

When installing the Foxboro FEM100 P0973CA, ensure it is mounted vertically on a suitable DIN rail expansion baseplate, either two-slot or four-slot, configured for your system size and redundancy needs. Maintain proper cable management and shielding of Fiber and twisted-pair cables to minimize signal interference. The enclosure and mounting environment should meet Class G3 contamination standards to protect sensitive electronics. DOE and EMC compliance suggest careful grounding and isolation practices to maintain system robustness.

Scheduled maintenance includes verifying LED diagnostic indicators for module operation and error status, coupled with routine inspections for physical damage or loose connectors. Firmware updates should be applied following Emerson/Foxboro recommendations to maintain network communication performance and security. Keeping replacement modules on standby reduces downtime during unplanned failures. Consult the Foxboro I/A Series documentation for detailed setup and diagnostic procedures.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626