Description

In factories where machines run non-stop and every second of downtime costs thousands, reliable logic processing keeps production lines synchronized and safe. Think of automotive assembly plants coordinating robotic welders with conveyor sequencing, or pharmaceutical batching systems ensuring precise ingredient dosing without human error. Water treatment facilities use these modules to manage pump interlocks and valve timing across vast networks of sensors, while oil refineries depend on them for flare stack controls and emergency shutdowns amid corrosive atmospheres and extreme vibrations. These environments demand hardware that handles real-time decisions under electrical noise, power fluctuations, and 24/7 thermal cycling—challenges that can scramble signals or delay responses in less robust gear. Engineers turn to dedicated state logic processors used in industrial automation for their ability to execute ladder logic or state machine programs independently, offloading controllers and boosting overall system responsiveness. Applicable in control systems from discrete manufacturing to continuous processes, the GE AD697SLP711A steps in as a proven workhorse, tackling tasks like sequence control, fault detection, and data buffering where timing precision prevents costly overruns or safety trips.

The GE AD697SLP711A shines in upgrades to legacy GE Fanuc setups, where plants need standalone intelligence without ripping out racks. It supports multi-tasking logic execution right at the edge of the process, making it ideal for OEMs building skids or integrators phasing in modern networks. Across power, chemical, and material handling sectors, this module maintains uptime by processing inputs from proximity sensors, limit switches, and encoders to drive outputs for motors, solenoids, and alarms—all while communicating status back to the main PLC or DCS.

Operators value the GE AD697SLP711A because it fits seamlessly into GE Series 90 or Genius I/O networks, reducing wiring complexity and enabling peer-to-peer data sharing among distributed nodes. In high-vibration zones like steel mills, its rugged build ensures stable operation without frequent recalibrations.

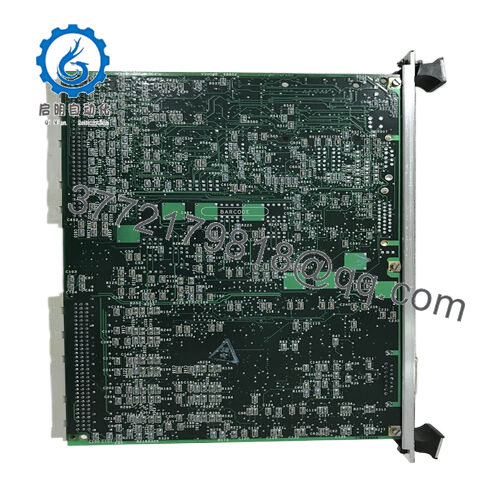

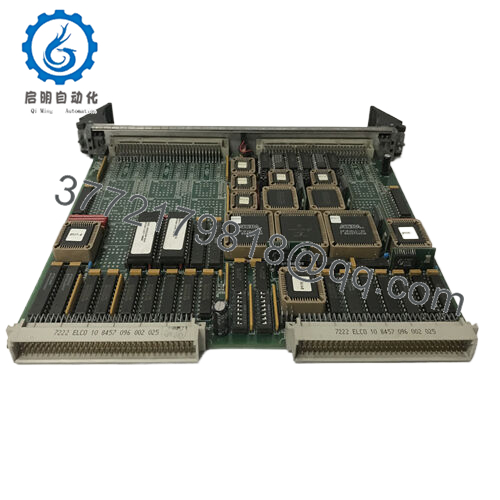

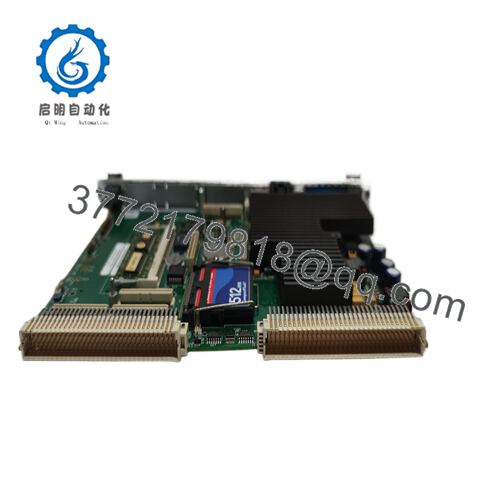

The GE AD697SLP711A is a State Logic Processor (SLP) module from GE Fanuc, built for real-time, multi-tasking control in programmable logic environments. It slots into rack-based architectures as an intelligent I/O handler, running user-defined state logic programs stored in its 128KB memory to manage sequencing, interlocking, and event-driven actions independently of the central CPU. Part of GE’s broader automation ecosystem, including Series 90-70 PLCs and Genius bus systems, the GE AD697SLP711A integrates via backplane or serial links, handling up to dozens of digital I/O points while supporting Modbus or Profibus for field communication.

- AD697SLP711A

- AD697SLP711A

What sets it apart for integrators is its autonomy: engineers download ladder or state diagrams via handheld programmers or PC tools, then let it operate standalone, freeing main controllers for higher-level tasks. This makes the GE AD697SLP711A invaluable in modular control cabinets, where it acts as a local brain for machine sections, improving scan times and fault isolation. Compatible with legacy GE hardware, it eases migrations in brownfield sites, and its diagnostics—accessible via LED indicators and bus queries—cut troubleshooting from hours to minutes. For system builders, the GE AD697SLP711A means scalable logic without custom PCBs, backed by GE’s extensive programming libraries for rapid deployment in demanding control systems

Field engineers praise the GE AD697SLP711A for its deterministic execution speeds, hitting 1 MHz processing that keeps interlocks snappy even with growing I/O counts—crucial for safety-rated sequences in presses or conveyors. Built tough with conformal-coated boards, it shrugs off humidity and dust in NEMA-rated panels, while its compact footprint slides into tight racks alongside power supplies and comm modules. Error-tolerant design flags open wires or shorts instantly, and the 128KB non-volatile memory retains programs through power cycles, minimizing reconfiguration hassles.

On the hardware front, the GE AD697SLP711A mounts securely with DIN rail or rack clips, featuring screw terminals for vibration-proof field wiring and front-access LEDs for at-a-glance status. Thermal management relies on passive convection, derated for 85°C hotspots without fans that could fail. Protocol support spans Modbus RTU for SCADA ties and Genius bus for peer modules, letting it share variables seamlessly in multi-drop networks—perfect for retrofits where protocols mix.

Reliability shines long-term: MTBF exceeds 100,000 hours in tested profiles, thanks to surge-protected I/O and watchdog timers that reset logic on hangs. Technicians report fewer nuisance trips versus generic processors, and firmware upgradability via GE tools extends life in evolving plants. Overall, the GE AD697SLP711A delivers integrator-grade stability that pays back in spared outages.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE AD697SLP711A |

| Brand | GE Fanuc |

| Type | State Logic Processor Module |

| Power Supply | 24 V DC nominal |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack or backplane in control cabinet |

| Dimensions | 150 mm (W) × 100 mm (H) × 30 mm (D) |

| Weight | 1.5 kg |

| Interfaces | Digital I/O (up to 16 in/8 out), Modbus, Profibus |

| Memory | 128 KB non-volatile |

| Processing Speed | Up to 1 MHz |

| Certifications | CE, UL for industrial use |

| Cooling | Passive convection |

| Environmental Rating | IP20, suitable for polluted industrial air |

Compatible Modules

IC697CPU731 – Paired CPU for Series 90-70 racks housing the GE AD697SLP711A in full PLC nodes.

IC670MDL644 – Digital input module that feeds signals directly to GE AD697SLP711A logic for sequencing.

IC660BBD020 – Genius bus interface expanding GE AD697SLP711A to remote drops.

IC697HSC700 – High-speed counter complementing GE AD697SLP711A for motion tasks.

IC660EBD024 – Electronic base for mounting GE AD697SLP711A in distributed setups.

DS3800HSAA – Legacy regulator board migratable alongside GE AD697SLP711A in turbine controls.

IC630MDL311 – 24V input expander sharing rack space with GE AD697SLP711A.

Size the cabinet for at least 10 cm clearance around the GE AD697SLP711A to aid airflow and cable bending, and verify 24 V DC supply ripple stays under 10%—use a dedicated UPS for logic-critical nodes. Ground the backplane chassis to earth via 6 mm² wire, and segregate I/O wiring by type (power separate from signals) to dodge EMI; test continuity post-termination with a megger at 500 V. Label channels per drawing revisions, and power up incrementally: rack first, then modules, monitoring LEDs for bus sync before loading programs

Maintenance stays straightforward for the GE AD697SLP711A: quarterly walks check terminals for creepage and dust on heatsinks, using compressed air only—no solvents that etch coatings. Poll diagnostics monthly via Genius network for discrepancy counts or memory errors, and archive logic backups pre-shutdown. Firmware flashes take under 10 minutes with GE’s Logicmaster tool during outages; swap spares hot if redundant, but cycle power otherwise. Stock one per 10 units site-wide, as lead times stretch—trained techs handle 90% of issues onsite.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626