Description

In high-stakes power generation environments where a glitch in the excitation system can force a turbine offline mid-ramp and cost millions in lost revenue or regulatory fines, engineers can’t afford the latency or fragility of legacy analog controls that mask faults until it’s too late. Legacy hydro and gas-fired plants running 1960s-vintage AVR setups frequently grapple with voltage instability from grid disturbances, brushless exciter noise, or de-icing heater overloads that traditional relays simply can’t differentiate from genuine faults. This becomes mission-critical during frequency-response events or black-start sequences where the generator must hold 95 % voltage regulation within 100 ms while logging every setpoint change for NERC audits. Enter the GE CM400RGICH1ACB, a robust digital excitation regulator from the COMPUSTA series that upgrades those brittle systems to full microprocessor-based control with adaptive PID tuning, built-in diagnostics, and seamless integration into modern SCADA without ripping out the existing field wiring or brushless exciter.

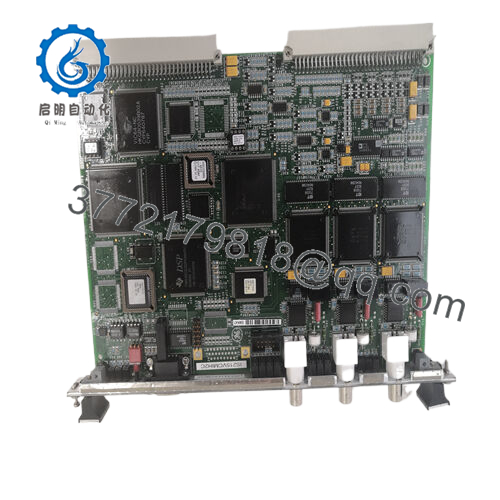

The GE CM400RGICH1ACB mounts in a standard 19-inch rack alongside the exciter bridge and communicates via dual RS-485 ports running Modbus RTU, letting it drop into existing plant networks for setpoint commands and status polling from the unit’s DCS or HMI. It processes 4–20 mA or ±10 V analog inputs from voltage transducers, current transformers, and power-system stabilizers, then drives the exciter field with a pulse-width-modulated (PWM) output rated for 250 A continuous — all while running a field-programmable AVR algorithm that auto-adjusts for temperature-induced drift in the rotor windings. On-board event sequencing handles soft-start, overflux protection (21), and loss-of-field (40) logic natively, so you no longer need external relays cluttering the panel. The regulator’s front-panel keypad and LCD let field techs tweak limits on the fly, but all changes are time-stamped and archived in non-volatile memory for post-event analysis.

- CM400RGICH1ACB

- CM400RGICH1ACB

| Specification | Details |

|---|---|

| Model Number | CM400RGICH1ACB |

| Brand | GE (now GE Vernova) |

| Type | Digital Excitation Regulator Module |

| Input Voltage | 115–230 VAC, 50/60 Hz (control power) |

| Operating Temp Range | –20 °C to +70 °C |

| Mounting Style | 19-inch rack (1U height) |

| Dimensions | 482 × 44 × 300 mm (W×H×D) |

| Weight | 5.2 kg |

| Interface/Bus | Dual RS-485 Modbus RTU, analog I/O terminals |

| Compliance | CE, UL, CSA, IEC 60255 |

| Supported Protocols | Modbus RTU, DNP3 optional |

| Typical Power Draw | 50 VA (control), 250 A field output |

Opting for the GE CM400RGICH1ACB means transforming a reactive excitation system into one that anticipates problems: the adaptive gain scheduling reduces voltage overshoot by up to 40 % during load dumps, while integrated de-excitation dumping cuts fault-clearing time from seconds to under 50 ms. Sites that once endured weekly manual tuning now run for months on factory defaults, with the built-in self-test routines flagging SCR bridge faults before they propagate to the generator. Over a decade, the reduction in unplanned outages and compliance paperwork often recoups the investment multiple times, especially in plants chasing ancillary-service revenue where every megawatt-hour of stable output counts.

The GE CM400RGICH1ACB thrives in hydro plants where it stabilizes penstock surges during peak-demand ramps, ensuring the generator holds synchronism even with 20 % load swings in under 200 ms. In combined-cycle gas turbines, it pairs with PSS2A stabilizers to meet grid-code reactive-power requirements, logging Q-V curves for real-time operator review. Fossil-fired synchronous condensers use it for blackout-recovery black-start, where the precise field-flashing sequence gets the machine online in minutes rather than hours.

CM400RGICH1AAA – Base analog input variant without digital comms

CM400RGACH1AEC – Enhanced version with Ethernet Modbus TCP

CM400RGACH2ACB – Dual-channel for redundant exciter setups

CM400RGACH1ABB – High-current field output for larger rotors

CM400RGICH1ADC – DC control power input for battery-backed sites

EX2100e – Modern successor for full retrofit migrations

UG-8 – Legacy analog regulator when staying fully vintage

Before energizing a GE CM400RGICH1ACB, confirm the exciter bridge SCRs are rated for the PWM output and that CT polarities match the regulator’s expected phase rotation — a reversal here is the top cause of initial undervoltage alarms. Use shielded 14 AWG for field wiring and terminate grounds at a single point to avoid loops. Load the factory default parameters via the keypad, then fine-tune the ceiling voltage and slope settings against the generator capability curve. After tie-in, run the built-in ramp test: the display should show steady 1.0 pu voltage with no ripple above 0.5 %. Field maintenance boils down to annual visual checks of the heat sink fins and a quick Modbus poll to verify setpoint tracking; most units hum along for years without intervention.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626