Description

The GE DS3800HSCG1C1C is typically deployed in GE Speedtronic Mark IV turbine control systems wherever high‑integrity signal isolation is needed between sensitive control electronics and higher-level field or drive signals. In real plants, this kind of high-level isolator board sits between the Mark IV core logic and devices such as drives, relays, or remote terminal blocks, helping protect the controller from noise, ground potential differences, and transient events that are common in large turbine and balance‑of‑plant equipment. Because it provides signal isolation and conditioning rather than pure processing, the GE DS3800HSCG1C1C is used in industrial automation where clean, reliable signals are essential for trip logic, permissives, and status monitoring, especially across long cable runs or mixed grounding zones. This makes it applicable in control systems for gas and steam turbines in power generation, cogeneration sites, and large industrial drives, where maintaining clear electrical separation between subsystems directly impacts uptime and diagnostic clarity.

In everyday operation, the GE DS3800HSCG1C1C helps ensure that Mark IV input and output channels “see” a conditioned, isolated version of the plant signals, so engineers can trust the status values and command paths feeding critical logic. It is also common in upgrade and life‑extension projects where operators retain their existing Mark IV cabinets and wiring but refresh individual boards to improve reliability and preserve spare‑part compatibility. By handling isolation at the board level instead of relying solely on external hardware, the module reduces wiring complexity and simplifies troubleshooting, because isolation, scaling, and basic conditioning are concentrated on a documented, rack‑mounted card rather than scattered through field panels.

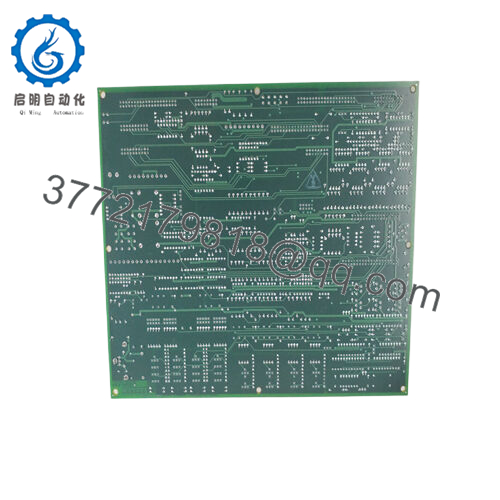

The GE DS3800HSCG1C1C is defined as a high-level isolator board within the GE Mark IV family, designed specifically to provide galvanic isolation and conditioning for higher‑level analog or discrete signals entering or leaving the control system. It belongs to the broader Speedtronic Mark IV turbine control platform, where modular boards are used for logic processing, I/O handling, protection, and interfacing with field equipment. Architecturally, the GE DS3800HSCG1C1C sits on the rack backplane, connecting on one side to the Mark IV bus through a modular edge connector and on the other side to cabling or terminal hardware that routes signals to the turbine or auxiliary systems. Its job is to isolate and shape those signals so that the core controller sees stable, predictable inputs and can drive outputs without directly exposing fragile electronics to external electrical conditions.

For control engineers and integrators, the value of the GE DS3800HSCG1C1C lies in how cleanly it integrates into existing Mark IV architectures and how much risk it removes from signal paths. Rather than adding third‑party isolation hardware and reworking panel layouts, plants can use a purpose‑built board that already matches the rack mechanics, connector scheme, and diagnostic expectations of the platform. This preserves existing documentation and training and supports structured troubleshooting, because technicians know that isolation and conditioning for certain signals are handled on a dedicated, identifiable card. In installations where system validation or regulatory approvals are important, keeping within the Mark IV component ecosystem also simplifies compliance compared with introducing ad‑hoc interface solutions.

- DS3800HSCG1C1C

- DS3800HSCG1C1C

The GE DS3800HSCG1C1C delivers its main technical strengths through a combination of signal isolation, conditioning accuracy, and robust physical design. As a high-level isolator, it is intended to handle higher‑level signals—often from drives, interface racks, or remote equipment—and provide a stable, isolated representation to the turbine control logic, improving noise immunity and reducing common‑mode interference. This is particularly important in turbine applications where long cable runs, multiple grounding zones, and high electromagnetic interference from large motors or switching devices can otherwise corrupt measurement and status lines.

Hardware design details such as a modular connector on one end and retention levers on the other allow the GE DS3800HSCG1C1C to be installed and removed quickly without stressing the backplane or adjacent boards. The card is populated with jumpers—typically eight—and at least one trimmer resistor, allowing configuration of certain operating parameters or ranges to match specific application requirements within the Mark IV system. This mix of on‑board adjustability and defined mechanical features reflects a design aimed at both adaptability and maintainability in dense turbine control racks.

In terms of compatibility, the GE DS3800HSCG1C1C is explicitly identified as a Mark IV series board and is meant to work with matching backplane, cabling, and terminal hardware in GE turbine controls. Its connector type and board function are aligned with other DS3800‑series modules, which means engineers can use it alongside standard Mark IV I/O, processor, and protection boards without changes to the underlying system architecture. This is important for plants that must maintain a consistent set of spare parts and minimize cross‑platform complexity across multiple units or sites.

Long‑term reliability of the GE DS3800HSCG1C1C is supported by its role as an isolation and conditioning module that shields the controller from harsh external conditions, reducing stress on core electronics. When installed in a clean, temperature‑controlled cabinet and used within specified electrical limits, boards of this class can remain in service for many years, especially when periodic inspections are performed and connectors are kept in good condition. Many aftermarket suppliers also offer tested and refurbished units, further extending service life for plants that plan to operate Mark IV controls well beyond their original design horizon

Detailed Technical Specifications

The table below summarizes key, human‑readable parameters for the GE DS3800HSCG1C1C as a high-level isolator board in the Mark IV family.

| Parameter | Value |

|---|---|

| Model | GE DS3800HSCG1C1C |

| Brand | General Electric (GE) |

| Series | Speedtronic Mark IV turbine control system |

| Product type | High-level isolator board |

| Board function | Signal isolation and conditioning between field/drive and controller |

| Connector type | Modular edge connector (approx. 34‑pin class) for rack backplane |

| Configuration elements | 8 jumpers and 1 trimmer resistor on board |

| Mounting | Plug‑in, rack‑mounted printed circuit board with retention levers |

| Intended system | GE Mark IV turbine/drive controls |

| Typical operating location | Turbine control panel or drive cabinet interior |

| Primary role in system | Electrical isolation, noise reduction, and signal level matching |

| Service status | Legacy component, supplied via third‑party distributors |

Related modules or compatible units

DS3800HSCG1A1A – Earlier or alternate high-level isolator variant in the same family, used where similar isolation and conditioning is required.

DS3800HFPG1C1B – Mark IV board often found in the same style of racks, complementing isolator cards in turbine control applications

DS3800NHVM1C1C – High-voltage related circuit board that may work alongside the GE DS3800HSCG1C1C in systems requiring additional voltage handling or interface functions.

DS3800DMEA1D1C – Motor exciter control–related board installed in Mark IV–based excitation or drive systems that share cabinets with isolator boards.

DS3800PC high-voltage assemblies (e.g., DS3800NHVM1C1C variants) – Associated PC board assemblies used with the same style of GE turbine and drive controls where high-level isolation is important.

Other DS3800HSCG series options – Closely related isolator models that differ by revision or configuration, used as functional substitutes depending on system design.

Installation notes and maintenance best practices

Before installing the GE DS3800HSCG1C1C, technicians should verify the correct slot assignment and orientation using the Mark IV panel drawings, since isolator boards are often tied to specific signal groups and misplacement can cause mismatched or missing signals. The modular connector and retention levers should be inspected for wear or contamination, and the backplane should be cleaned as needed to ensure a firm, low‑resistance connection that will withstand vibration and thermal cycling inside the cabinet. Any jumpers or the on‑board trimmer resistor should be set according to system documentation or cloned from a known‑good unit to avoid configuration mismatches between redundant racks or similar units.

During service, the GE DS3800HSCG1C1C should be included in routine visual inspections, focusing on connector integrity, discoloration, or component damage that might indicate overheating or transient events on connected circuits. Plants often incorporate this board into periodic signal-path checks to confirm that isolated signals match their sources within expected tolerances, especially on critical trip and permissive lines. Keeping at least one tested spare on hand and documenting jumper and trimmer settings makes it easier to swap the card during outages and send the removed unit for professional testing and refurbishment, supporting high availability in legacy Mark IV automation systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626