Description

The GE DS3800NFOA1C1D is a GE Speedtronic Mark IV–series control board typically used in heavy-duty gas and steam turbine environments where reliable signal processing and I/O management directly affect unit availability and protection. In real plants, it will usually sit inside turbine control panels, handling part of the interface between field devices and the core logic that governs fuel control, sequencing, and protective trips. Engineers encounter the GE DS3800NFOA1C1D during retrofit projects, life-extension programs, and critical spare planning where the goal is to keep a mature GE turbine fleet running safely while preserving existing wiring and cabinet layouts. Because it is used in industrial automation and is applicable in control systems managing high-value rotating assets, this board helps connect pressure transmitters, limit switches, speed or status signals, and other instrumentation into the Mark IV architecture in a repeatable and maintainable way.

Typical users include power utilities, independent power producers, refineries, and large process plants that still run legacy GE control systems and prefer proven, field-tested hardware over disruptive full-platform migrations. In these facilities, the GE DS3800NFOA1C1D plays a part in ensuring that turbine start-up sequences, load ramps, and emergency shutdowns behave consistently, even after decades of service. It supports key functional tasks such as signal conditioning, isolation, and routing so that the central processor receives clean, reliable data under conditions of electrical noise, vibration, and temperature swings. For operators and maintenance teams, this translates into fewer nuisance trips, more predictable troubleshooting, and a clearer path to phased modernization where boards can be replaced one at a time without changing the overall control philosophy.

Product introduction and positioning

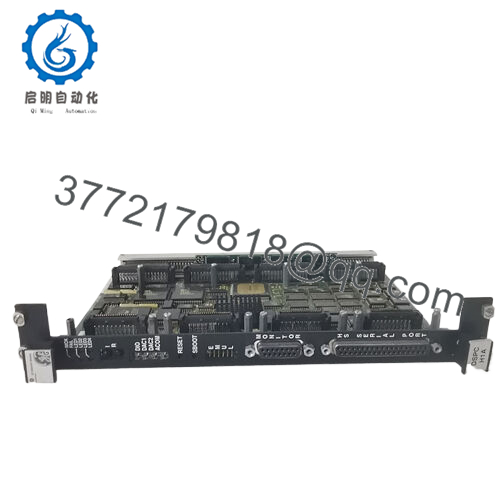

The GE DS3800NFOA1C1D is an electronic circuit board from General Electric’s DS3800 series, designed for use within GE Speedtronic Mark IV turbine control systems as a functional I/O or signal interface module. While the exact function can vary depending on cabinet configuration, it is commonly used as part of the signal interface layer that conditions, isolates, or routes process and status signals between field devices and the main turbine controller. In a standard Mark IV panel, the board plugs into a dedicated backplane slot, with edge connectors mating to rack wiring that leads to terminal blocks, marshalling panels, or other DS3800/DS200 modules. This placement lets it play a focused role in the control architecture, sitting between noisy, real-world process signals and the more sensitive logic and processor hardware.

Within the overall system design, the GE DS3800NFOA1C1D helps segment the control system into manageable hardware functions: some boards provide logic and computation, others handle power supplies, and boards like this one deal with interfacing tasks that must be robust but serviceable. That separation is valuable for engineers because it simplifies both troubleshooting and safety analysis—issues can be narrowed down to a single card position instead of an entire cabinet. Integrators benefit because the board is designed to work within GE’s established wiring practices and terminal conventions, making it easier to integrate into existing cabinets without redesigning every connection point. For plants committed to maintaining a GE-based automation stack, the GE DS3800NFOA1C1D offers a practical way to preserve original system behavior while using reconditioned or replacement hardware that fits mechanically and electrically.

Key technical features and functional benefits

Functionally, the GE DS3800NFOA1C1D is engineered for stable, repeatable performance in the demanding environment of turbine control, where momentary signal failures can result in costly trips or unsafe operating conditions. It typically supports conditioned signal paths with defined ranges, impedance, and isolation so that field inputs—whether discrete contacts or analog signals—arrive at the controller with minimal noise and distortion. This type of performance is essential during rapid transient events such as start-up, load shedding, or grid disturbances, when accurate feedback helps the turbine respond in a controlled, predictable way.

From a hardware perspective, the GE DS3800NFOA1C1D follows the DS3800 mechanical and electrical format, using a plug-in card design with edge connectors that engage a Mark IV backplane. That arrangement supports fast card replacement during planned outages, where technicians can de-energize the cabinet, extract a suspect board, insert a known-good unit, and resume operation after standard checks. The board construction is typically oriented toward industrial environments: components are mounted to withstand vibration, and creepage and clearance distances are laid out with the high-noise, high-energy context of turbine panels in mind.

Compatibility is a strong practical advantage of the GE DS3800NFOA1C1D, as it is intended to operate with other DS3800-series and related GE modules rather than as a standalone device. This alignment reduces engineering overhead when maintaining a homogeneous GE control system, allowing users to leverage existing documentation, wiring diagrams, and spare-part pools. For plants that have already invested in DS3800-based control cabinets, using a board from the same family helps avoid non-standard adapters or custom mounting hardware, keeping the installation clean and supportable over time.

In terms of long-term reliability, the GE DS3800NFOA1C1D benefits from conservative design practices typical of turbine control boards of its era, such as generous derating of components and layout choices that prioritize robustness over density. Combined with controlled cabinet environments—where temperature, dust, and humidity are managed—this allows the board to remain in service for many years with only routine inspection and occasional replacement. For asset managers, that kind of lifecycle performance is valuable because it supports long-term planning for spares and upgrades without frequent unplanned replacements.

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | GE DS3800NFOA1C1D |

| Brand | General Electric |

| Product type | Turbine control system circuit board (I/O or signal interface module) |

| System family | GE DS3800 series for Speedtronic Mark IV turbine controls |

| Primary function | Signal conditioning, isolation, and interfacing between field devices and controller |

| Typical application | Gas and steam turbine control panels in industrial automation and power generation |

| Power supply | Low-voltage direct current via DS3800 backplane (control-level power) |

| Mounting | Plug-in card, edge-connected to Mark IV or DS3800 rack backplane |

| Interfaces | Control-level input and output channels routed through cabinet and terminal wiring |

| Operating environment | Enclosed control cabinets with managed temperature and ventilation in turbine areas |

| Cooling | Natural or forced convection within panel airflow |

| Maintenance approach | Replaceable board, swap-out via front access to control rack |

- DS3800NFOA1C1D

Related modules or compatible units

DS3800NPMB1A1A – GE DS3800-series power or interface board that can reside in the same Mark IV control cabinets as GE DS3800NFOA1C1D.

DS3800HIOA1C1D – Related input isolator board from the same generation, handling signal isolation for field inputs.

DS3800HMPK – Processor or main logic board used in GE Mark IV controls that receives conditioned signals from interface cards.

DS3800NEPB – Excitation or drive-related board used in turbine and generator applications alongside other DS3800 cards.

DS200 series modules – Later-generation GE boards that can appear in mixed cabinets for phased modernization while retaining DS3800 hardware.

DS3800NPMB1A1A – Often listed together with GE DS3800NFOA1C1D in industrial parts catalogs, indicating common usage contexts and cabinet locations.

Installation notes and maintenance best practices

When integrating the GE DS3800NFOA1C1D into an existing Mark IV panel, engineers should first verify that the rack slot, backplane connector, and wiring assignments match the intended function documented in the plant’s control schematics. Careful attention to grounding and shielding is important to keep process signals clean; shield drains should be landed as specified in site standards to avoid ground loops that could distort measurements or introduce intermittent faults. Clearance around the board should be checked to ensure no cable bundles or tie wraps exert mechanical stress on the card once it is seated in the backplane, especially in cabinets that have seen multiple retrofit rounds. Before energizing, it is prudent to cross-check terminal designations and any jumpers or configuration elements against the existing installation or OEM drawings.

Over the life of the unit, the GE DS3800NFOA1C1D should be inspected during scheduled outages for signs of heat stress, contamination, or connector wear. Simple practices such as verifying tightness of terminal connections, confirming that card guides and latches are intact, and keeping vent paths in the panel free of dust can extend board service life significantly. When control-system firmware or higher-level logic is modified, engineers should observe how associated signals behave in trends and alarms to ensure the board’s signal paths continue to operate within expected ranges. Keeping at least one fully tested spare GE DS3800NFOA1C1D on hand, labeled with its test date and any configuration notes, provides an additional layer of risk reduction in critical turbine applications.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626