Description

In legacy GE Speedtronic turbine control systems, particularly those built around the Mark IV series, maintaining precise excitation for generator fields or auxiliary motors is critical to stable operation and preventing unplanned outages. Fluctuations in field current can lead to voltage instability, loss of synchronism, or even damage to the rotor windings, especially in large-frame gas or steam turbines where excitation demands are high and environmental conditions challenging. Situations like starting up after maintenance, responding to load changes, or operating in high-vibration environments often expose weaknesses in older excitation hardware, leading to unreliable performance or difficult troubleshooting. The GE DS3800NMEA1J1C addresses these challenges as a dedicated motor exciter control board, providing regulated DC excitation current with the robustness needed for continuous duty in industrial automation and process control applications. Engineered for the DS3800 family, it ensures consistent field strength, supporting high reliability in turbine-driven generators where even brief excitation lapses can cascade into costly downtime. In power generation setups requiring precise control over electromagnetic fields for rotor magnetization, the GE DS3800NMEA1J1C becomes essential for achieving long-term system stability and operational safety.

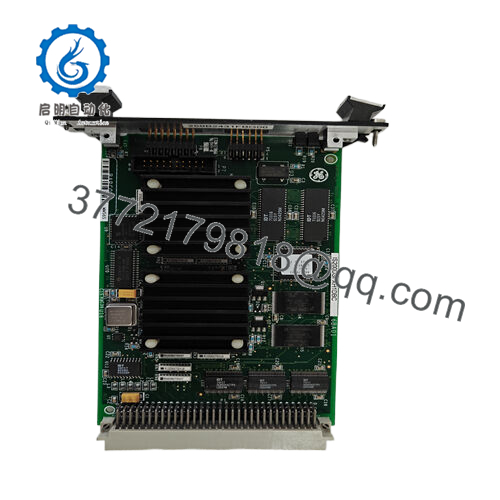

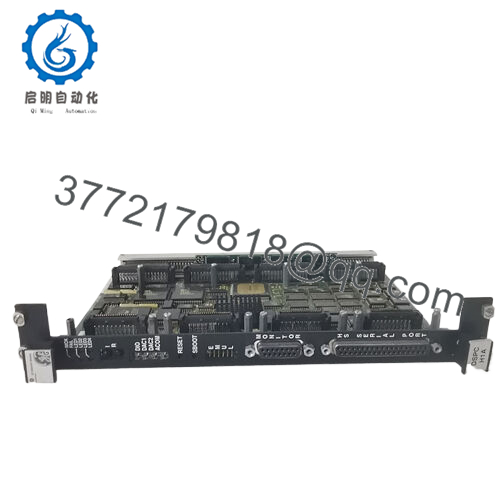

The GE DS3800NMEA1J1C functions as a motor excitation board within the Mark IV Speedtronic architecture, integrating directly into the control rack via edge connectors to interface with the system’s backplane and other DS3800-series cards. It regulates the DC current supplied to the exciter field windings, using feedback loops to maintain stable output despite variations in load or input power, while coordinating with regulator cards and power supplies for seamless operation. Positioned in the excitation control section of the stack, it receives signals from the main controller processors and drives the field through SCR firing or similar circuits, supporting closed-loop control that keeps generator voltage steady. The board handles typical Mark IV communication over parallel bus structures, allowing triple modular redundant voting for fault tolerance in critical paths. No external protocols are required, as it operates natively within the Speedtronic ecosystem, though it preserves diagnostics like LED status indicators and test points for field verification. In the broader automation stack, the GE DS3800NMEA1J1C sits at the power conversion level, bridging microprocessor-based control logic to high-current field outputs, enabling reliable turbine synchronization and load response in both simplex and TMR configurations.

| Specification | Details |

|---|---|

| Model Number | DS3800NMEA1J1C |

| Brand | General Electric (GE) |

| Type | Motor Exciter Control Board |

| Input Voltage | 120 V AC (typical Mark IV rack supply) |

| Operating Temp Range | -30°C to +65°C (standard for DS3800 series) |

| Mounting Style | Rack-mounted PCB with edge connectors |

| Dimensions | Approx. 8.25 in x 4.18 in (standard DS3800 form factor) |

| Weight | Approx. 0.8 lb |

| Interface/Bus | Mark IV parallel backplane |

| Compliance | UL, CSA (typical for era) |

| Supported Protocols | N/A (native Speedtronic bus) |

| Typical Power Draw | ~12 W |

- DS3800NMEA1J1C

- DS3800NMEA1J1C

Selecting the GE DS3800NMEA1J1C delivers a level of excitation reliability engineered for the demands of turbine environments, where consistent field current directly impacts generator performance and overall plant availability. Its design emphasizes durability, with components selected to withstand electrical noise and thermal cycling, ensuring long-term performance without drift in calibration or unexpected failures. This translates to reduced engineering overhead during upgrades or retrofits, as the board drops into existing Mark IV racks with minimal reconfiguration. In use, the precise regulation minimizes voltage overshoots during transients, protecting downstream equipment and extending rotor life through stable magnetization. Maintenance efficiency gains come from built-in test points and straightforward component layout, allowing technicians to verify operation quickly without extensive disassembly. Overall, the GE DS3800NMEA1J1C provides practical value by supporting fault-tolerant operation that scales with system complexity, lowering both initial integration efforts and long-term risks in high-stakes power generation.

The robust construction of the GE DS3800NMEA1J1C also contributes to performance consistency in noisy electrical settings common to turbine halls, helping maintain tight control loops even under heavy load swings.

The GE DS3800NMEA1J1C is widely deployed in power generation facilities operating large gas and steam turbines, where it handles excitation for main generators or auxiliary motors under conditions demanding critical system uptime and resistance to vibration. In combined-cycle power plants, for instance, it supports stable field control during rapid load changes, ensuring voltage regulation that prevents grid disturbances. Oil and gas upstream applications often use it in turbine-driven compressors, leveraging its reliability in remote, harsh environments with extreme temperatures and continuous operation requirements. Petrochemical refineries appreciate the board for process control environments involving turbine-powered pumps or blowers, where fast response to excitation demands maintains production flow without interruptions. These industrial automation setups benefit from its ability to integrate into redundant Mark IV configurations, providing the high reliability needed for assets where downtime costs escalate quickly.

DS3800NMEA1H1E – Variant with adjusted component values for higher excitation currents.

DS3800NMEA1L1J – Similar board optimized for specific auxiliary motor applications.

DS3800NMEC1F1C – Related motor field regulator with enhanced feedback features.

DS3800NMEA1P1K – Higher-power version for demanding field requirements.

DS3800NEPA1C1B – Exciter power board often paired for complete systems.

DS3800NMEC1D1D – Earlier generation motor exciter with compatible footprint.

DS3800NFCD1S1J – Firing circuit board used in conjunction for SCR control.

Before installing the GE DS3800NMEA1J1C, confirm exact revision compatibility with your Mark IV rack configuration, as suffix differences affect connector pinouts or calibration. Check rack power supply stability and ensure adequate airflow, since excitation boards generate moderate heat during full-load operation. Verify that any auxiliary daughterboards are securely mounted if present, and review the system schematic for proper jumper settings on adjacent cards. During setup, use a multimeter at test points to confirm initial voltages before applying field load, and torque edge connectors firmly to avoid intermittent contacts from vibration. For ongoing maintenance, inspect for dust accumulation or capacitor bulging during scheduled outages, and log LED status or analog outputs annually to trend performance. A simple functional test by monitoring field current response to step changes can catch degradation early, keeping the board reliable through its extended service life in turbine control systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626