Description

In gas and steam turbine control systems, achieving high reliability and fault-tolerant operation is paramount to avoid unplanned outages that can cost millions in lost production. Older turbine management platforms often struggle with single points of failure, limited diagnostics, and vulnerability to component degradation in harsh environments like high vibration, temperature extremes, or electrical noise. This becomes critical during peak demand periods or in remote installations where rapid repair isn’t feasible.

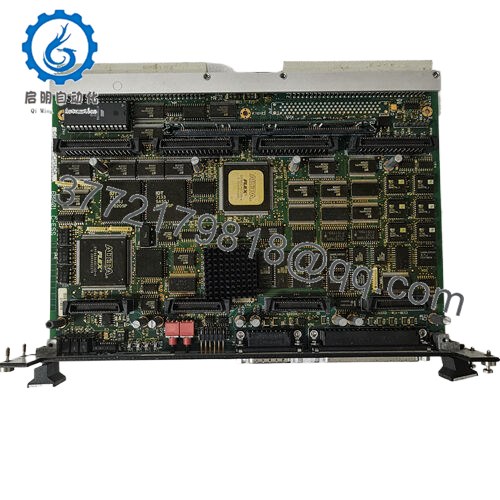

The GE DS3815PAED1A1A addresses these challenges directly as part of the Speedtronic Mark IV series, providing robust printed circuit board functionality with PROM-based firmware for consistent control logic execution. The GE DS3815PAED1A1A supports triple modular redundancy (TMR) architectures, where voting mechanisms across redundant paths ensure system stability even if one channel faults. It’s particularly valuable in industrial automation setups requiring process control continuity, such as when interfacing auxiliary signals or handling PROM-stored parameters that define turbine sequencing, protection thresholds, and I/O mapping.

Engineers turn to the GE DS3815PAED1A1A in retrofit scenarios for legacy Mark IV systems, where maintaining high reliability without full platform replacement is key. Its design incorporates industrial-grade components resistant to EMI and thermal stress, making it essential for extending the life of critical assets in power generation or heavy mechanical drives.

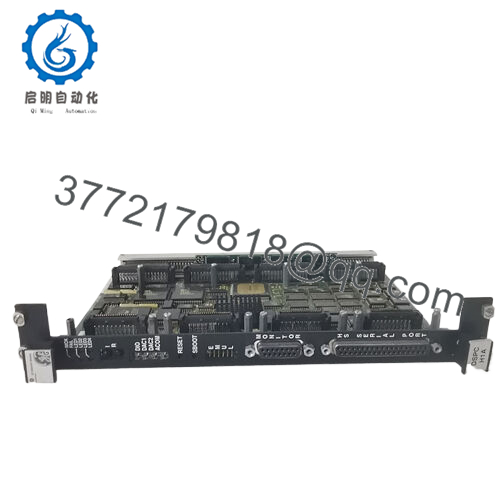

The GE DS3815PAED1A1A integrates into the Mark IV turbine control rack as a PROM assembly board, typically mounting alongside processor and I/O modules to store and execute non-volatile program data. It interacts via the system’s internal highways, allowing seamless data exchange with controller cores, communication interfaces, and field I/O terminals.

Positioned in the control layer of the automation stack, the GE DS3815PAED1A1A holds critical firmware that governs startup/shutdown sequences, alarm logic, and parameter sets. This placement ensures quick access during real-time operations without relying on external storage. The board supports diagnostic routines inherent to Mark IV, where redundant controllers cross-check PROM integrity and flag discrepancies to the operator interface.

In TMR configurations, it contributes to voted outputs for protective functions like overspeed or flame detection. Compatibility with other DS38xx family boards allows mixed configurations in the same chassis, facilitating gradual upgrades. The GE DS3815PAED1A1A uses established Mark IV interconnects, minimizing latency in control loops while providing stability in noisy plant environments.

- DS3815PAED1A1A

| Specification | Details |

|---|---|

| Model Number | DS3815PAED1A1A |

| Brand | GE (General Electric) |

| Type | PROM Assembly Circuit Board |

| Input Voltage | 5V DC / 24V DC (backplane dependent) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Rack-mounted (Mark IV chassis) |

| Dimensions | Approx. 12 x 9 inches (standard PCB form) |

| Weight | Approx. 1.2 kg |

| Interface/Bus | Mark IV internal highways |

| Compliance | Industrial standards (UL, CSA equivalents) |

| Supported Protocols | Proprietary Mark IV TMR |

| Typical Power Draw | <15W |

Selecting the GE DS3815PAED1A1A delivers enduring stability in turbine control applications through its PROM-based design, which preserves critical logic even during power cycles or faults. This non-volatility ensures long-term performance consistency, reducing risks associated with data corruption that could trigger spurious trips or unsafe conditions.

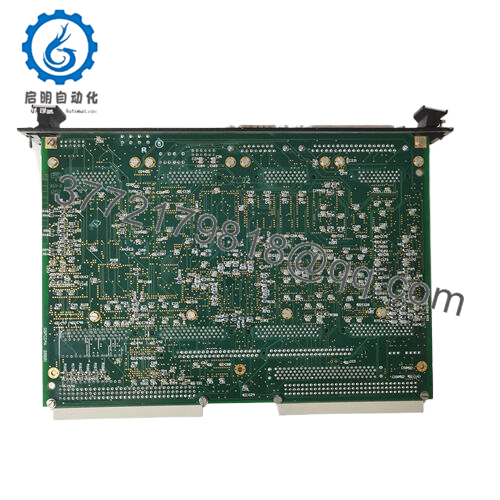

Engineered for the demanding cycles of gas and steam turbines, the board’s rugged construction withstands vibration and thermal cycling, contributing to lower failure rates compared to earlier Speedtronic generations. In practice, this translates to extended mean time between failures and simpler spares management.

The GE DS3815PAED1A1A also reduces engineering overhead by maintaining compatibility with existing Mark IV documentation and tools, allowing straightforward firmware verification or updates without extensive revalidation. Plants relying on this module often achieve higher availability metrics, as its role in redundancy supports seamless failover and minimizes control disruptions.

The GE DS3815PAED1A1A is commonly found in power plants operating frame-class gas turbines, where it stores protection and sequencing programs essential for critical system uptime under base-load or peaking duty, even in elevated ambient conditions.

In combined-cycle facilities, the module supports integrated steam turbine controls, handling complex interlocks while enduring the humidity and heat typical of HRSG proximity.

Refinery and pipeline compressor stations also deploy it for drive turbine management, prioritizing fast response and reliability in explosive atmospheres or remote locations demanding minimal intervention.

Across these process control environments, the GE DS3815PAED1A1A proves its value in sustaining 99.99%+ availability targets.

DS3815PAAA1D1A – Base PROM board variant for standard applications

DS3815PABA1E1A – Slave highway daughter board for expanded communication

DS3815PDPA – PROM board with EPROM support for field updates

DS3815PTCA – Terminal controller PROM assembly for I/O interfacing

DS3815PXCA1C1A – Shift register board companion for data handling

DS3815CCMD – Universal communication processor for network ties

DS3800HCMA – Related base board for PROM mounting in earlier configs

Prior to installing the GE DS3815PAED1A1A, confirm the PROM revision matches your system’s firmware baseline—mismatches can cause boot failures or unrecognized logic. Inspect the rack for secure backplane connectors and ensure sufficient slot ventilation to prevent overheating in fully loaded chassis.

Verify ESD precautions during handling, as static can corrupt PROM contents. During initial power-up, monitor the Mark IV diagnostic display for board acknowledgment and checksum validation.

Maintenance typically involves periodic visual checks for component discoloration or connector wear, especially in dusty or corrosive settings. Run built-in self-tests via the control interface quarterly to confirm PROM integrity.

An annual extraction for cleaning and reseating helps maintain contact reliability. These straightforward practices support decades of service from the GE DS3815PAED1A1A in active systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626