Description

In high-stakes turbine control and generator excitation systems, a single failure in the analog output chain can force an immediate runback or full trip — costing megawatts and risking forced-outage penalties. The root cause is often the same: drift or outright burnout of the small-signal op-amps and drivers that translate the regulator’s 0–10 V or 4–20 mA commands into real field current. Older Mark I, Mark II, and early Mark IV Speedtronic panels used discrete boards with dozens of through-hole components that become impossible to repair once the original 4000-series CMOS and 741-style amplifiers go obsolete. When you’re staring at a stack of red-lit fault codes and no spare parts in the warehouse, the clock is ticking.

This is precisely why engineers still specify the GE IC3600AOAA2 decades after its introduction. The IC3600AOAA2 is a rugged, single-width analog output card designed for the original Mark I/II Speedtronic turbine control backplane. It delivers four independent, galvanically isolated 4–20 mA channels (or 0–10 V with a simple shunt change) directly from the 16-bit data bus of the LM6000, Frame 5, or Frame 7 control core. Built on GE’s proven card-edge connector and heavy conformal coating, the IC3600AOAA2 survives the heat, vibration, and electrical noise inside a turbine enclosure where commercial PLC analog cards would fail in months. In an era when many plants are extending turbine life well beyond 40 years, this card keeps legacy Mark I/II systems in compliance with modern grid codes without forcing a multimillion-dollar control retrofit.

The IC3600AOAA2 plugs straight into any open Q-line slot on the Mark I/II card rack and talks to the core processor through the classic three-bus architecture (QBA, QDA, QCA). Calibration is done with the familiar multi-turn pots right on the faceplate — no laptop or Hand-Held Monitor required — and each channel has its own fuse and test point so you can verify loop integrity without pulling wires. Isolation exceeds 1500 V channel-to-channel and channel-to-logic, preventing ground loops that plague non-isolated cards in excitation and governor retrofits.

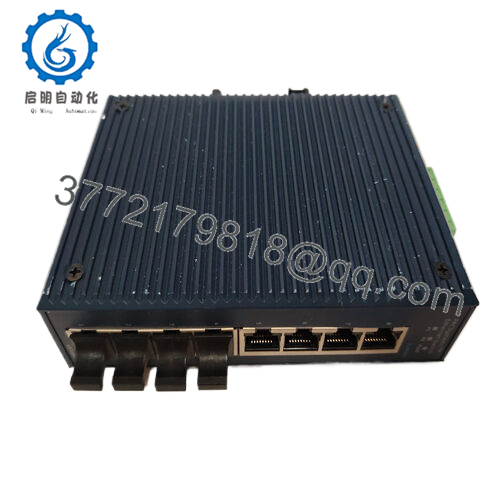

- IC3600AOAA2

- IC3600AOAA2

| Specification | Details |

|---|---|

| Model Number | IC3600AOAA2 |

| Brand | General Electric (GE Power) |

| Type | 4-channel isolated analog output card |

| Output Range | 4–20 mA (field-convertible to 0–10 V) |

| Resolution | 12-bit (1 part in 4096) |

| Load Capability | 0–750 Ω @ 24 V compliance |

| Operating Temp Range | 0 °C to 70 °C (turbine enclosure rated) |

| Mounting Style | Single-width Speedtronic Mark I/II card slot |

| Dimensions (H×W×D) | 11.5 × 1.3 × 8.5 in (standard Q-card) |

| Weight | 0.9 kg |

| Interface/Bus | Mark I/II Q-bus (3-card-edge fingers) |

| Compliance | ANSI/IEEE C37.90, UL component recognition |

| Isolation | 1500 Vrms channel-to-channel & to logic |

| Typical Power Draw | 5 W from +5 V rack supply |

Choosing the IC3600AOAA2 today means you keep the turbine online instead of scrambling for emergency control upgrades. Plants that stock even a handful of these cards report near-zero forced outages caused by analog output failures, even on machines that have been through multiple hot-section overhauls. The galvanic isolation eliminates the mysterious drift problems that appear when someone inadvertently grounds a field device through a different path, and the 750 Ω drive capability means you can still push current loops across long cable runs to the exciter building without adding repeaters. In practice, the card’s robust design and simple calibration have saved countless weekends that would otherwise be spent reverse-engineering a failed third-party replacement.

The real payoff shows up during a major inspection: pull the card, wipe the edge connector with a little IPA, check the four fuses, and you’re back in service — often in under fifteen minutes. That kind of predictability is priceless when the grid operator is calling every hour.

You’ll still find the IC3600AOAA2 driving governor actuators on Frame 5s in Southeast Asia, positioning inlet guide vanes on early LM2500 packages in marine service, and controlling legacy static exciters in hydro plants that never migrated to EX2100. Any site running Mark I or Mark II panels — whether gas turbine, steam turbine, or compressor drive — depends on these cards for critical positioning loops where response time and long-term stability directly affect megawatt output and grid stability.

IC3600AOAA1 – Earlier two-channel version, lower drive capability

IC3600A0AB1 – Companion 4-channel analog input card for closed-loop testing

IC3600Q0AA1 – Quad DAC board sometimes used as drop-in substitute (check calibration range)

IC3600SVZA1 – Servo valve amplifier card often paired in governor applications

IC3600LIBB1 – Logic interface buffer for Mark II systems upgraded with newer core

DS3820AOAA – Direct DS3800-series replacement for Mark IV migrations

IC3600EPSU1 – Regulated power supply module typically installed in same rack

Before inserting the IC3600AOAA2, verify the gold edge fingers are clean and that the card ejectors are fully open — these old racks can be stiff. Confirm the rack still has the original +5 V / ±15 V distribution; low ripple on the analog rails is essential for holding 0.1 % accuracy over temperature. Set your loop power source to external if the field device doesn’t supply it — the card itself does not source 24 V. A quick continuity check from the faceplate test points to the field terminal blocks catches most wiring errors before you power up.

In service, glance at the four green “channel active” LEDs during walkdowns; no light usually means a blown fuse rather than a failed card. Recalibration every five years (or after a major lightning event) is sufficient for most plants — just feed a precision 4.000 mA and 20.000 mA source and tweak the zero and span pots while watching the actuator position. Keep one calibrated Fluke 754 in the control room and the job takes less than ten minutes per channel.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626