Description

In every Mark I and Mark II Speedtronic panel, there is one card that nobody thinks about until it fails: the main 28 VDC power supply regulator. When the original single-output regulator card drifts, sags, or quietly dies, every logic card in the <R> core loses voltage at once. The result is an immediate master trip, loss of flame detection, fuel valves slamming shut, and a very expensive forced outage. One Gulf Coast refinery lost $1.8 million in margin from a single 14-hour trip caused by a tired IC3600SPSx card.

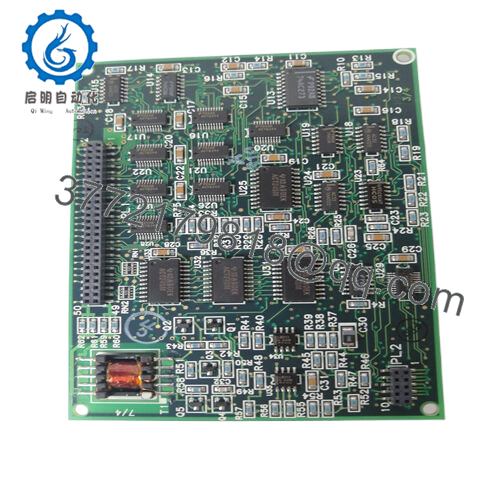

The GE IC3600SPSU1 is the upgraded, high-reliability 28 VDC power supply module that replaced the fragile earlier versions. It takes raw 125 VDC battery power from the panel’s station battery, regulates it down to an ultra-stable 28 VDC ±0.5 %, and feeds the entire control core through the backplane. Critically, the GE IC3600SPSU1 adds active current limiting, over-voltage crowbar protection, and a front-panel voltage test points pair that lets you monitor output without pulling the card. Plants that have standardized on the GE IC3600SPSU1 almost never see a control-power-related turbine trip again.

You pull the GE IC3600SPSU1 out of stores when you are tired of explaining to management why the turbine tripped on “low control voltage,” when insurance auditors flag inadequate power-supply redundancy, or when you are extending outage intervals and refuse to leave a 1970s regulator as the weakest link in an otherwise bulletproof protection chain.

- IC3600SPSU1

- IC3600SPSU1

How the Product Works & Fits into a System

The GE IC3600SPSU1 occupies the dedicated power-supply slot (usually position 1 or 2) in the Mark I/II card file. It accepts 100–140 VDC from the station battery or battery charger through heavy screw terminals on the rear of the rack. A high-efficiency series-pass regulator with discrete transistors and a precision zener reference delivers up to 15 A continuous at 28 VDC directly onto the backplane power rails. Output ripple is held below 50 mV even at full load, and transient response recovers in microseconds after load steps.

On-board diagnostics include a green “Power Good” LED and an adjustable over-voltage shutdown set roughly 10 % above nominal. If the output tries to climb past 31 V (typically from a failed pass transistor), a thyristor crowbar instantly shorts the output and blows the upstream fuse—protecting every logic card downstream. A small meter jack on the faceplate lets you plug in a DMM and read exact voltage without opening the panel. Because the GE IC3600SPSU1 is completely analog and isolated from the control logic, it satisfies the independence requirements of NFPA 85 and API-670 place on critical power sources.

| Specification | Details |

|---|---|

| Model Number | IC3600SPSU1 |

| Brand | GE Energy |

| Type | 28 VDC regulated power supply module |

| Input Voltage | 100–140 VDC (125 VDC nominal) |

| Operating Temp Range | –10 °C to +65 °C |

| Mounting Style | Mark I / Mark II card file, slot 1 or 2 |

| Dimensions | 12.25 in × 8.5 in × 1.5 in |

| Weight | 1.1 kg |

| Interface/Bus | Direct backplane + rear screw terminals |

| Compliance | Designed for NFPA 85, API-670 environments |

| Supported Protocols | None (pure power module) |

| Typical Power Draw | 450 W max output, ~15 A at 28 VDC |

Real-World Benefits

With the GE IC3600SPSU1 installed, control voltage becomes one less thing that keeps I&C engineers awake at night. The active current limit prevents a shorted logic card from dragging the entire bus down, and the crowbar has saved countless downstream cards during rare transistor failures. Output voltage is so stable that flame-scanner gain pots and speed-channel setpoints no longer drift with battery charger float voltage changes—something the old linear supplies could never claim.

Maintenance crews appreciate the front-panel test points and the fact that the card can be swapped live in most panels without tripping the turbine (provided the backup supply or battery holds the bus). One combined-cycle plant I supported replaced every original regulator with GE IC3600SPSU1 units and recorded zero control-power trips over the next eight years.

Typical Use Cases

You will find the GE IC3600SPSU1 feeding every active Mark I and Mark II panel still in revenue service: Frame 5, 6, and 7 gas turbines in simple-cycle and combined-cycle plants, mechanical-drive units on natural-gas pipelines and FPSOs, and steam turbines in refineries and district-energy systems. It is mandatory wherever the plant runs unattended or remote-started and where even a few minutes of lost generation is measured in five or six figures.

Compatible or Alternative Products

IC3600SPSK1 – Physically identical but rated for only 8 A (lighter loads)

IC3600EPSU1 – 125 VDC version for panels that never converted to 28 V logic

IC3600SPSV1 – Adds second isolated 28 VDC output for servo drives

IC3600EPSN4 – Modern switching supply replacement (same footprint, higher efficiency)

IC3600QSPA1 – Spare parts kit with transistors and crowbar SCR

IC3600AVSA1 – Auxiliary 5 V regulator often mounted on the same backplane

Setup Notes & Maintenance Insights

Before insertion, measure incoming 125 VDC at the rear terminals—anything outside 100–140 V will prevent proper regulation. Verify polarity; the card has no reverse-protection diode. Once seated, adjust the small trim pot on the front edge until the test jacks read exactly 28.0 VDC with normal load. Tighten the two captive screws firmly; vibration can cause intermittent high-resistance connections on the edge fingers.

During routine walkdowns, glance at the green LED and tap the test jacks once a month. Voltage should stay within ±0.3 V year-round. If the LED ever goes out, swap the card immediately—there is no graceful degradation mode. Keep one calibrated spare on site; the large electrolytic filter caps are the only age-sensitive components and are readily available from legacy suppliers.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626