Description

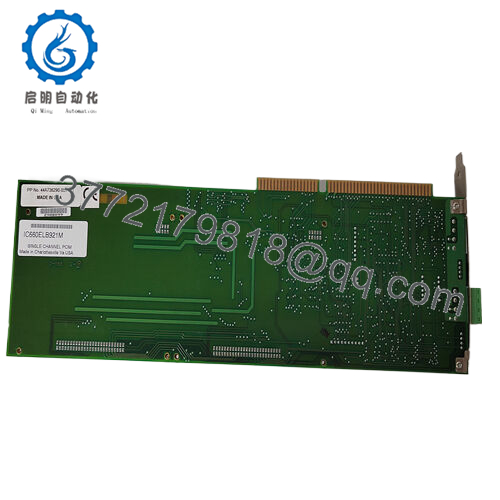

Product Model: GE IC660BBA105K

Product Brand: GE Fanuc / GE Intelligent Platforms

Product Series: Series 90-30 & Series 90-70 Modular Bases

Product Features:

• Engineered baseplate for secure PLC rack and I/O mounting

• High-integrity mechanical support with modular expansion capability

• Excellent compatibility with GE Series 90 automation hardware

• Designed for rugged industrial environments with reliable service life

Technical Specifications

| Specification | Detail |

|---|---|

| Model | GE IC660BBA105K |

| Brand | GE Fanuc / GE Intelligent Platforms |

| Series | Series 90-30 / Series 90-70 Compatible Baseplate |

| Material | Industrial-grade steel with protective finish |

| Mounting Style | Rack and panel mounting interface |

| Compatible PLC Modules | Series 90 CPU, I/O, power modules |

| Mounting Holes | Pre-drilled standard industrial pattern |

| Cable Routing Supports | Integrated attachment points |

| Durability | Resists vibration, thermal cycling |

| Application Environment | Industrial indoor/outdoor enclosures |

| Panel Integration | DIN rail / cabinet frame |

| Weight | Typical industrial base weight |

- IC660BBA105K

Product Role & System Fit

When assembling a programmable logic controller (PLC) system, the physical foundation matters as much as the electronics it supports. At that intersection sits the GE IC660BBA105K, a purpose-built baseplate and rack mounting module that delivers both structural integrity and reliable integration with GE Fanuc automation systems. It forms the backbone of modular control architectures, providing a stable platform for CPUs, I/O cards, power supplies, and communication interfaces.

In practice, the GE IC660BBA105K serves as the first mechanical element designers specify when planning a new installation or retrofit. PLC racks don’t float; they anchor to a base that keeps them rigid, aligned, and protected from vibration and environmental stresses. This base assembly does exactly that, engineered to mate with Series 90-30 and Series 90-70 hardware while allowing room for expansion. Installers appreciate that it is not merely a piece of sheet metal but a thoughtfully designed frame that simplifies wiring, reduces installation time, and supports long-term maintainability.

Compatibility is a strong point. Whether your facility runs multiple automation generations or is migrating from older GE system families, the GE IC660BBA105K typically fits into the broader GE modular ecosystem without costly adapters. It integrates with standard DIN rail sections or panel mounting schemes, letting engineers plan layouts that reflect workflow logic rather than mechanical compromise. In this context, the model name isn’t just an identifier; it represents a standard base upon which complex industrial processes can be confidently built and scaled.

In many facilities, especially those with hybrid automation infrastructures (mixing legacy and newer hardware), this base assembly acts as a bridge. The GE IC660BBA105K enables teams to reuse existing modules while maintaining consistent mechanical support. Its footprint and mounting hole patterns are familiar to control panel fabricators, meaning less re-engineering and fewer surprises during commissioning. Even experienced electrical designers note that having a reliable base cuts project risk — bad rack alignment can cascade into wiring errors, loose connectors, or premature module wear.

Simply put, this module is where your automation system begins structurally. Other components hang off it — logically, electrically, and physically. Selecting the right base isn’t glamorous, but it is foundational; and the GE IC660BBA105K delivers stability that seasoned integrators trust.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626