Description

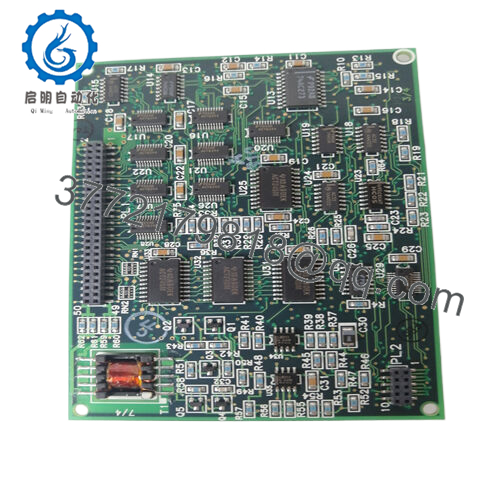

Product Model: GE IC660BBD101S

Product Brand: GE Fanuc / Emerson Automation

Product Series: Genius I/O

Product Features:

• Eight configurable AC I/O channels for flexible input/output operation up to 115 VAC.

• Integrated diagnostics and LED indicators for circuit state and module status.

• High block-to-block isolation and robust design for industrial environments.

• Selectable input filtering and electronic fuse protection per circuit.

Technical Specifications Table

| Specification | Details |

|---|---|

| Module Model | GE IC660BBD101S |

| Series | Genius I/O Block |

| Number of I/O Channels | 8 Configurable (input/output/tristate) |

| Operating Voltage | 93–132 VAC (Nominal 115 VAC) |

| Frequency | 47–63 Hz |

| Input Filter Time | 10–100 ms selectable |

| Output Current (steady state) | 2 A per channel |

| Inrush Current Peak | 25 A up to 2 cycles |

| Block-to-Block Isolation | 1500 V |

| LED Indicators | Module status + per-channel LEDs |

| Heat Dissipation | 16 W (inputs) / 43.5 W (outputs at 2 A) |

| Operating Temp | 0–60 °C |

| Dimension (HxWxD) | ~8.8″ x 3.3″ x 3.9″ |

- IC660BBD101S

Product Role & System Fit

At its core, the GE IC660BBD101S is an I/O interface block in the Genius I/O family originally from GE Fanuc, now under Emerson Automation. It doesn’t operate as a standalone controller; rather, it integrates into a broader automated network where it communicates status data and control signals between field devices and a host CPU or bus controller.

What sets this block apart from simpler terminal boards is its configurability. Each of the eight circuits can function as an input, output, or even a tristate input, providing versatility to handle a variety of signal types without swapping hardware. That means a single GE IC660BBD101S can support mixed operational roles on a machine line — a real advantage when panel space or budget is tight.

Compatibility with Genius Bus communications ensures the block works seamlessly within distributed control systems, enabling controllers to read statuses and command outputs as if they were local I/O on the central rack. For engineers maintaining older GE PLC systems or slowly transitioning to newer architectures, this module fits into existing network designs without massive rewiring or software changes.

Because control power is drawn from the field I/O voltage, there’s no need for a separate power supply for the block. This simplifies wiring and reduces the number of components technicians must maintain. Whether it’s part of a packaging machine or an industrial heater control panel, the GE IC660BBD101S integrates reliably and predictably.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626