Description

In modern industrial automation environments, maintaining precise temperature control while keeping I/O signal integrity across dozens or hundreds of thermocouples and RTDs can quickly become a bottleneck. Noise pickup on long sensor runs, cold-junction drift, ground loops, and the sheer density of wiring often force engineers into expensive shielded cable runs or multiple remote I/O islands just to keep measurement errors under control. When a process demands high-accuracy analog inputs in electrically noisy areas—think turbine halls, paper machines, or chemical reactors—any compromise on signal quality directly translates to lost product, tripped safety systems, or regulatory headaches.

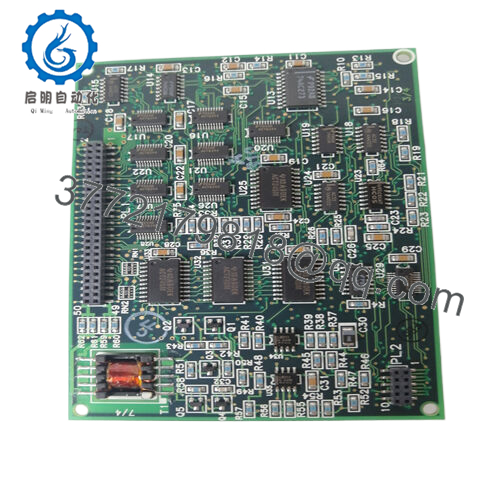

This is exactly where the GE IC660EBA020 earns its place. As a 16-channel thermocouple and millivolt input block in the Genius I/O family, the GE IC660EBA020 was designed from the ground up for distributed process control applications that cannot tolerate the latency or single-point-of-failure risk of centralized I/O racks. Instead of pulling every sensor wire back to a PLC cabinet hundreds of feet away, you mount the block close to the measurement points, convert signals locally with individual cold-junction compensation, and send clean, linearized data over a single robust Genius bus cable. The result is dramatically lower installation cost, far better noise immunity, and the kind of high-reliability temperature monitoring that plants running 8,760-hour years depend on.

The block becomes essential whenever you face tight temperature tolerances (±0.5 °C or better) in harsh locations, need to mix thermocouple types on the same module without external converters, or want to eliminate the chronic drift problems that plague older 4–20 mA temperature loops. It’s the difference between fighting ground-loop errors every outage and simply trusting the data that shows up in your DCS or Series 90-70 controller.

The GE IC660EBA020 lives on the Genius I/O bus, a peer-to-peer, token-passing network that GE (now Emerson) introduced in the late 1980s and still supports actively in thousands of plants worldwide. Each block is fully autonomous: it handles its own cold-junction measurement, linearization, open-wire detection, and range checking before placing engineering-unit data directly on the bus. A host controller—whether a Series 90-30, 90-70, Rx3i PAC, or even a third-party PLC with a Genius Bus Interface—simply reads the pre-processed values with no additional scaling code required.

Diagnostics are built deep into the architecture. The block continuously reports channel health, CJC status, and bus errors back to the handheld communicator or the host, so operators spot a drifting thermocouple or loose connection long before it affects the process. Redundancy is straightforward: dual-bus cables and redundant Genius controllers let you achieve bumpless control transfer in critical loops. Because the GE IC660EBA020 is a true distributed node, you can spread blocks across an entire plant floor while still keeping scan times under 10 ms for the whole network. In practice, that means one bus can easily serve temperature monitoring for an entire boiler island or drying line without forcing you into faster, more expensive fieldbus technologies unless you actually need them.

- IC660EBA020

- IC660EBA020

| Specification | Details |

|---|---|

| Model Number | GE IC660EBA020 |

| Brand | GE (now Emerson) |

| Type | 16-Channel Thermocouple/mV Input Block |

| Input Voltage | 24 VDC (18–56 VDC range) |

| Operating Temp Range | 0 °C to 60 °C |

| Mounting Style | Direct panel or DIN-rail with adapter |

| Dimensions | 8.83″ × 3.56″ × 4.42″ (224 × 90 × 112 mm) |

| Weight | 4 lb (1.8 kg) |

| Interface/Bus | Genius I/O (dual RJ-45 or terminal) |

| Compliance | CE, UL, CSA, Class I Div 2 |

| Supported Protocols | Genius proprietary (89.3 kbaud) |

| Typical Power Draw | 8 W |

Choosing the GE IC660EBA020 means you stop treating temperature measurement as a wiring problem and start treating it as a solved subsystem. Individual channel isolation (250 VAC continuous) kills ground loops before they start, while on-board CJC and upscale/downscale burnout detection ensure you never act on bad data during a critical heat-up sequence. Plants routinely see MTBF figures well beyond 500,000 hours because there are no internal relays or optocouplers to wear out—just solid-state electronics and a proven power supply design that has been in continuous production for decades.

Maintenance teams love the block because troubleshooting rarely requires a meter. The four diagnostic LEDs plus the handheld terminal tell you exactly which channel has an open thermocouple or CJC fault in seconds. Spare parts remain readily available, and the configuration is stored non-volatile, so swapping a block during an outage is a five-minute job instead of a re-commissioning exercise. In short, the GE IC660EBA020 delivers the kind of long-term performance consistency that lets you focus engineering resources on process optimization instead of chasing sensor drift.

The GE IC660EBA020 shows up most often in power generation—especially combined-cycle and cogeneration plants where turbine metal temperatures, bearing drains, and boiler skin points all demand reliable thermocouple reads 24/7. Pulp and paper mills use it extensively around recovery boilers and lime kilns, environments that combine high heat, chemical exposure, and constant vibration. Food-grade steam systems and pharmaceutical autoclaves also rely on it when validation requires traceable, high-density temperature data without the complexity of smart transmitters.

In all these settings, the drivers are the same: continuous uptime in harsh conditions, fast data cycles for cascade control, and the need to keep hundreds of sensors online with minimal wiring infrastructure. The block’s Class I Div 2 rating means you can mount it directly in the process area, cutting cable runs by 70–80 % compared to traditional home-run wiring. That alone often pays for the module in the first installation.

GE IC660EBA021 – RTD version (Pt100, Ni120, Cu10) for applications needing higher accuracy at moderate temperatures

GE IC660EBA023 – Mixed thermocouple/RTD block when you have both sensor types on the same skid

GE IC660EBA026 – Current-source thermocouple block for grounded junctions and higher noise immunity

GE IC660EBA100 – 8-channel relay output block commonly paired for heater control

GE IC660BBA020 – 24/48 VDC analog input block for pressure, level, or 4–20 mA temperature loops

GE IC660BBD020 – 24 VDC source/sink digital input block for limit switches and valve feedback

GE IC660BBR100 – Genius Bus Redundancy Interface for dual-cable fault-tolerant networks

Before you drop the GE IC660EBA020 into a system, confirm you have 24 VDC loop power available at the mounting location and at least 2 inches of clearance above and below for convection cooling. Verify your Genius bus terminators are correctly set (75 Ω on the last block of each segment) and that the host controller firmware supports Genius diagnostics—most Rx3i and 90-70 CPUs do out of the box. If you’re adding to an existing bus, check total power budget; each block pulls about 8 W, and the power supply bricks are typically rated for 30–40 W per segment.

Day-to-day maintenance is minimal. Glance at the four status LEDs during walkdowns: steady green means happy, flashing red points you straight to the faulty channel. Every couple of years, cycle power and watch the diagnostics report to confirm CJC calibration hasn’t drifted (it almost never does). Connector terminals are spring-cage style, so a quick tug test during outages confirms wiring integrity. If you ever need to replace the block, the configuration is downloaded automatically from the bus controller or handheld, so no channel-by-channel re-entry is required.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626