Description

The GE IC660EBA026 is a field-mounted analog block widely used in industrial automation wherever reliable low-voltage analog measurement and control are needed close to the process equipment rather than in a central cabinet. Typical environments include skid-mounted systems, packaged equipment, and distributed I/O islands in process plants where running long analog signal cables back to the control room would add cost, noise, and complexity. In water treatment, food and beverage, and light chemical processing, engineers deploy GE IC660EBA026 blocks next to instruments such as pressure transmitters, level sensors, and positioners, allowing compact wiring and quick access for maintenance. The block is used in control systems that rely on the Genius I/O network, so it fits naturally into existing GE Fanuc architectures where distributed I/O and deterministic communications are important.

On OEM machinery and skids, GE IC660EBA026 is often mounted in local junction boxes to gather multiple 0–10 V or similar low-voltage analog signals and present them to the main PLC as a single bus node. This is particularly useful on dosing skids, HVAC air-handling units, compressors, and burner management auxiliaries, where a mix of flow, temperature, or position feedback needs to be wired quickly and queried over a robust fieldbus. Because the module is powered from a 24–48 VDC supply and designed as part of the Genius family, it is applicable in control systems that must balance long-term maintainability with compatibility to installed GE Fanuc equipment. Integrators choose GE IC660EBA026 when they want distributed analog capabilities that are diagnostics-ready and proven in industrial service, without redesigning the entire control platform.

Product introduction and positioning

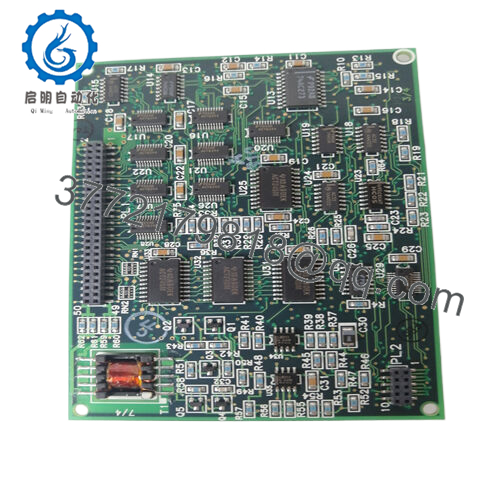

The GE IC660EBA026 is an analog Genius I/O electronics block from GE Fanuc, used to interface multiple low-voltage analog signals to a Genius network for processing by a host PLC or controller. It is typically paired with a matching terminal assembly (such as IC660TBA026) that provides field wiring terminals while GE IC660EBA026 contains the active electronics and communication circuitry. Functionally, this module serves as a distributed analog input and, in many configurations, limited analog output resource for Genius-based control systems, exposing channel data and diagnostics to the PLC over the serial bus.

Within the architecture of a GE Genius control system, GE IC660EBA026 is installed as a remote I/O block on the network segment, addressed and configured using standard Genius tools so that the host PLC sees each analog channel as a regular register in its I/O map. This architecture lets engineers move the measurement points closer to process instruments, minimizing analog cable runs while centralizing logic in a Series 90, Series Six, or other GE-compatible controller equipped with a Genius bus controller. For engineers and integrators, GE IC660EBA026 is valuable because it combines multiple analog channels, industrial-grade diagnostics, and robust communications in a compact, field-mountable form factor, making it a strong option for both new Genius-based projects and expansions of existing systems.

- IC660EBA026

- IC660EBA026

Key technical features and functional benefits

The GE IC660EBA026 provides multiple analog channels in a single block, commonly described as supporting four inputs and two outputs in the 0–10 V range, which fits many standard industrial transmitters and actuators. By concentrating these channels in one field device, it reduces the number of remote blocks needed for small process areas, helping keep network configuration and spares management simple. Its design includes integrated electronics that condition the incoming signals, translate them into digital values, and handle communication with the Genius bus, effectively offloading much of the low-level analog processing from the host PLC.

From a hardware standpoint, GE IC660EBA026 is intended as a rugged, field-mountable Genius block that can be installed close to equipment in industrial enclosures. Powered typically from a 24–48 VDC supply, it is designed to operate in the kind of temperature and electrical noise environments found in production plants, with encapsulated or protected electronics for long-term durability. Pairing it with the correct terminal assembly gives reliable screw or clamp wiring, strain relief, and clear separation between field and electronics, which is important during maintenance and when swapping electronics assemblies.

Compatibility is a core strength of the GE IC660EBA026. It is part of the Genius I/O family and is supported by control systems that include Genius bus controllers and configuration tools from GE Fanuc and Emerson. This means that it can coexist on the same network as digital blocks, specialty measurement blocks, and other analog units, all managed under the same addressing and diagnostic scheme. For plants that standardized on Genius I/O, this compatibility allows incremental additions of GE IC660EBA026 blocks without introducing new networking standards or training requirements.

Long-term reliability is enhanced by the Genius diagnostics model and the way GE IC660EBA026 interacts with system tools. The block can report status information, helping maintenance teams identify channel faults, power issues, or communication problems before they cause process upsets. Because it forms part of a longstanding GE ecosystem, there is a mature supply chain for replacement units, refurbished stock, and repair services, enabling plants to keep Genius-based analog I/O in service for many years.

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | IC660EBA026 analog electronics block |

| Brand | GE Fanuc / Emerson Genius I/O |

| Product type | Field-mountable analog I/O electronics block for Genius network |

| Typical analog configuration | 4 analog inputs and 2 analog outputs (low-voltage range) |

| Signal range | Nominal 0–10 volts direct current for channels (application dependent) |

| Power supply | 24 to 48 volts direct current, external supply |

| System platform | Genius I/O systems used with GE Fanuc PLCs and controllers |

| Mounting | Field or panel mounting with matching terminal assembly (e.g., IC660TBA026) |

| Network interface | Genius serial I/O bus communications |

| Typical diagnostics | Channel and block status reported to host via Genius diagnostics |

| Associated terminal assembly | IC660TBA026 or compatible terminal base for field wiring |

| Typical application environment | Industrial automation cabinets, junction boxes, and skid panels |

Related modules or compatible units

IC660BBA026 – Companion Genius analog block model from the same family, used where the BBA variant is preferred by design or inventory policy.

IC660TBA026 – Terminal assembly that provides the field wiring base for GE IC660EBA026, forming a complete field-mountable block.

IC660BBA023 – Thermocouple input Genius block for temperature measurement, often used alongside GE IC660EBA026 in mixed analog applications.

IC660EBA023 – Another analog electronics block variant, typically matched to different terminal hardware and signal requirements

IC660CBB901 – Genius bus controller module used in PLC racks to communicate with distributed Genius blocks such as GE IC660EBA026

IC660BSM021 – Bus Switching Module referenced in Genius documentation for advanced network configurations involving analog blocks.

IC660ELB921 – PC interface module for Genius networks, useful when engineering workstations need direct access to blocks like GE IC660EBA026.

Installation notes and maintenance best practices

When planning installation of GE IC660EBA026, engineers should verify that the 24–48 VDC supply is correctly sized and protected, with proper grounding and shielding in accordance with Genius I/O guidelines. The block and its terminal assembly should be mounted on a solid surface that provides adequate mechanical support and cable management, with enough clearance for heat dissipation and for technicians to access terminals for testing or replacement. Careful attention to field cable routing, separation from high-voltage power conductors, and adherence to recommended earth and shield terminations helps maintain signal quality on the analog channels. Addressing and configuration parameters should be planned ahead so the block’s Genius device number and channel definitions align cleanly with the host PLC logic.

For maintenance, GE IC660EBA026 benefits from periodic inspection of terminal tightness, enclosure sealing, and cable strain relief to prevent intermittent faults. Technicians should review Genius diagnostics and channel status during routine plant checks or shutdowns, looking for recurring communication errors or channel alarms that may indicate wiring degradation or device problems. Because the electronics assembly can typically be replaced separately from the terminal base, many users keep spare GE IC660EBA026 units on hand to minimize downtime during a failure. Maintaining up-to-date records of configuration, calibration settings, and network layout further speeds recovery and ensures any replacement block is configured correctly and safely returned to service.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626