Description

The GE IC693360-BA is typically used in plants that already rely on the GE Fanuc Series 90-30 platform and need robust, rack-based digital control in demanding industrial automation environments. It is commonly deployed in production lines, process skids, and utility support systems where a large number of discrete field devices—such as limit switches, proximity sensors, pushbuttons, relays, and indicator lamps—must be monitored or driven reliably over long operating cycles. In real projects, engineers specify the GE IC693360-BA when they want to increase or standardize digital I/O density on existing Series 90-30 racks without changing the core control strategy or rewriting high-level logic. It is applicable in control systems for packaging, material handling, machine tools, and building services, where deterministic response, clear diagnostics, and straightforward wiring practices directly affect uptime and maintenance costs. Because it shares the mechanical form factor and backplane interface of the 90-30 family, the GE IC693360-BA fits naturally into brownfield cabinets, allowing integrators to expand I/O capacity, segment signals into clean groups, and keep panel layouts consistent across multiple machines or lines.

In process industries and infrastructure projects, the GE IC693360-BA is often part of panels that supervise pumps, fans, dampers, and interlocks—tasks that depend on reliable digital feedback and command signals rather than complex analog control. Engineers use it to aggregate status points (running, tripped, permissive, faulted) and to distribute output commands for contactors, solenoid valves, and alarm beacons within a single Series 90-30 rack section. This makes it useful in water and wastewater plants, chemical auxiliaries, and energy support systems, where wiring is spread over local junction boxes but centralized into a rack-based PLC near the process area. Because it is designed for industrial environments with electrical noise, temperature variation, and mechanical vibration, the GE IC693360-BA supports long-term service in control rooms and field cabinets alike, helping operators maintain clear visibility of machine states and execute safe start/stop sequences under tight operational constraints.

Product Introduction & Positioning

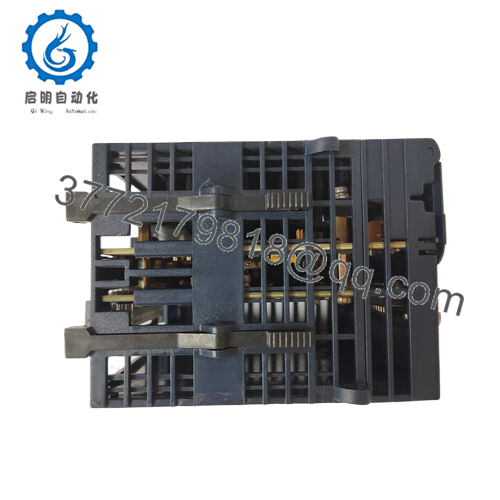

The GE IC693360-BA is a modular digital I/O unit for the GE Fanuc Series 90-30 programmable logic controller family, designed to add a block of discrete signal handling to an existing rack-based control system. Within a PLC architecture, it occupies a single I/O slot on the Series 90-30 baseplate and connects to the CPU over the backplane, exposing its input and/or output points to the controller’s discrete image tables. Depending on configuration, the module is typically used as a medium-to-high density digital module, consolidating multiple field channels into a compact footprint that simplifies both wiring and diagnostics. The GE IC693360-BA aligns with the Series 90-30 design philosophy: modular hardware, deterministic operation, and clear mapping between field wiring and program references, which helps engineers maintain orderly control logic and straightforward documentation.

Positioned as an industrial-grade module rather than a low-cost board-level device, the GE IC693360-BA targets applications where reliability and maintainability are more important than simply minimizing hardware count. It fits into architectures where a central Series 90-30 CPU manages multiple racks of I/O distributed around the plant, and where each digital module must provide solid isolation, noise immunity, and clear status indication at the front of the panel. For integrators and OEMs, the GE IC693360-BA adds value by supporting standard field voltage levels, offering a familiar terminal layout, and behaving predictably across the full operating temperature and loading range. This allows them to reuse control templates, keep spare parts manageable, and meet customer expectations for long-term support on a proven GE platform. In short, the GE IC693360-BA is positioned as a dependable building block for discrete control in any Series 90-30-based system.

- IC693360-BA

Key Technical Features & Functional Benefits

From a functional standpoint, the GE IC693360-BA is designed to deliver stable digital signal handling for medium-to-large control applications, emphasizing predictable behavior and robust isolation rather than exotic features. Its channels are engineered to withstand the electrical noise, surges, and switching transients commonly found in industrial cabinets, helping protect both the PLC CPU and upstream field devices. This robust design improves system stability, especially in environments with frequent motor starts, contactor actuation, or long field cable runs where induced noise is a concern. For end users, the result is fewer nuisance trips and more consistent input status, which in turn cuts down on troubleshooting time.

Hardware-wise, the GE IC693360-BA uses the standard Series 90-30 module form factor, making it easy to integrate into existing 5-slot or 10-slot baseplates. Its front terminal arrangement typically groups channels in a practical way, allowing field wiring to be organized by machine section, safety zone, or device type. LED indicators on the front panel (for channel status and module health) give technicians immediate feedback when a point changes state or a wiring issue occurs, which is particularly valuable during commissioning and maintenance. Because it draws power from the 5 V backplane supply, the module does not require separate auxiliary supplies for its logic side, simplifying panel design and reducing the number of components that must be sized and specified.

The GE IC693360-BA is also designed with compatibility in mind. It works seamlessly with Series 90-30 CPUs, power supplies, and other I/O modules, allowing engineers to mix it with analog, high-speed, or communication modules in the same rack without special considerations beyond normal power budgeting and slot allocation. Signal levels and timing are aligned with typical industrial standards, ensuring that the module can interface with common sensors, pushbuttons, relays, and interposing interfaces. Over the long term, this compatibility helps facilities maintain a consistent hardware ecosystem—spares, wiring conventions, and software libraries can be shared across multiple panels, simplifying lifecycle management and training.

Reliability over years of continuous operation is a core benefit of the GE IC693360-BA. Its construction, along with the broader Series 90-30 mechanical and electrical design, supports operation across an industrial temperature range and typical non-condensing humidity conditions when installed in a properly rated enclosure. The module’s passive cooling and lack of moving parts reduce wear-out mechanisms, and when combined with a solid power supply and good grounding practices, it can run for long intervals without intervention. For operators managing critical lines, this steady-state reliability is often more important than pushing the absolute limit of I/O density.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE IC693360-BA |

| Brand | GE Fanuc / General Electric |

| Product Type | Series 90-30 digital I/O module |

| System Platform | GE Fanuc Series 90-30 programmable logic controller family |

| Power Supply Source | 5 Volts Direct Current from Series 90-30 rack backplane |

| Typical Backplane Current Draw | In line with standard Series 90-30 digital modules (exact value per official datasheet) |

| Channel Type | Discrete digital channels for field signals (input and/or output, per variant) |

| Nominal Field Voltage | Standard industrial DC or AC control voltage (refer to datasheet for exact rating) |

| Operating Temperature Range | Approximately 0 to 60 degrees Celsius, in a suitable control cabinet |

| Storage Temperature Range | Approximately -40 to 85 degrees Celsius |

| Mounting Style | Rack-mounted in Series 90-30 baseplate on DIN or panel rail |

| Front Indication | Status LEDs for module health and individual channel groups (model-dependent) |

| Environmental Rating | Industrial control cabinet installation, non-condensing humidity |

| Cooling Method | Passive air cooling within a ventilated enclosure |

Related Modules or Compatible Units

IC693360-BC – Digital module from the same Series 90-30 family, used in similar discrete automation applications where rugged industrial-grade performance is required.

IC693350-BC – Single-slot Series 90-30 CPU that drives digital modules like the GE IC693360-BA in machine and process control systems.

IC693CPU351 – Mid-range Series 90-30 CPU commonly paired with multiple I/O racks, including digital modules in the IC693360 series.

IC693374-GR – High-density 24 VDC input module used alongside the GE IC693360-BA when large numbers of discrete inputs are required.

IC693MDL730 – 12/24 VDC positive logic output module often used to switch solenoids, relays, and lamps in systems that also use the GE IC693360-BA for digital points.

IC693PWR330 – High-capacity Series 90-30 power supply that provides backplane power for CPUs and multiple digital I/O modules.

Installation Notes & Maintenance Best Practices

Before installing the GE IC693360-BA, engineers should verify that the chosen Series 90-30 baseplate has sufficient slot capacity and that the rack power supply can support the cumulative 5 V backplane current of the CPU and all I/O modules. Cabinet layout should allow enough free space for cable routing and ventilation around the rack, maintaining ambient conditions within the specified operating temperature range. Grounding and shielding practices are particularly important for digital modules: shield drains for field cables should be terminated at designated points, and high-voltage or high-current conductors should be physically separated from low-level control wiring to minimize noise coupling. It is also good practice to label terminals and use consistent wire numbering so that each channel on the GE IC693360-BA can be traced quickly during commissioning or troubleshooting.

Maintenance routines for the GE IC693360-BA generally focus on periodic visual inspection and signal verification rather than frequent hardware replacement. Technicians should check that the module is firmly seated in the baseplate, that terminal screws or spring-clamp connections remain tight, and that there are no signs of overheating or contamination in the cabinet. Front-panel LEDs should be reviewed during both normal operation and test sequences to confirm that expected inputs and outputs are transitioning correctly. When changes are made in the field—such as adding new devices or repurposing channels—documentation and PLC comments should be updated so that the mapping between program addresses and GE IC693360-BA terminals remains accurate. Keeping at least one spare module in stock for critical lines helps reduce downtime if a rare hardware failure occurs.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626