Description

The GE IC693TCM302B is a dedicated temperature control module used in industrial automation wherever a GE Fanuc Series 90‑30 PLC needs precise, closed‑loop control of multiple thermal zones from a single rack slot. It is typically deployed in applications such as ovens, furnaces, extruders, heat‑treating equipment, packaging tunnels, and environmental chambers where temperature accuracy, repeatability, and stable ramp/soak profiles matter more than simple on/off thermostatic control. Engineers use the GE IC693TCM302B when they want to bring thermocouple or RTD signals directly into the PLC and execute PID loops on a specialized module, instead of relying on a mix of stand‑alone temperature controllers and analog cards. This approach centralizes temperature logic, alarm handling, and recipe management inside the Series 90‑30 program while keeping the time‑critical loop math on the module itself.

In plastics and rubber processing, the GE IC693TCM302B is commonly tied to barrel zones, die heads, and mold circuits, where each zone requires its own tuning and limits but must still follow coordinated heat‑up and cool‑down sequences. Food and beverage plants use it to manage tunnel ovens, shrink tunnels, and CIP or pasteurization systems that depend on tight temperature control and documented process profiles. In specialty chemical and pharmaceutical environments, it helps control reactor jackets, dryers, or stability chambers where temperature overshoot or drift directly affects product quality and batch release decisions.

Because the module integrates both temperature inputs and control outputs, the GE IC693TCM302B is equally applicable in retrofit projects and new builds where engineers want to replace older panel‑mount controllers with a single, PLC‑centric solution. It reduces panel complexity, simplifies wiring, and makes it easier to standardize alarm logic, setpoint management, and data logging at the PLC level—while still delivering fast, deterministic loop execution dedicated to temperature control tasks.

Product Introduction & Positioning

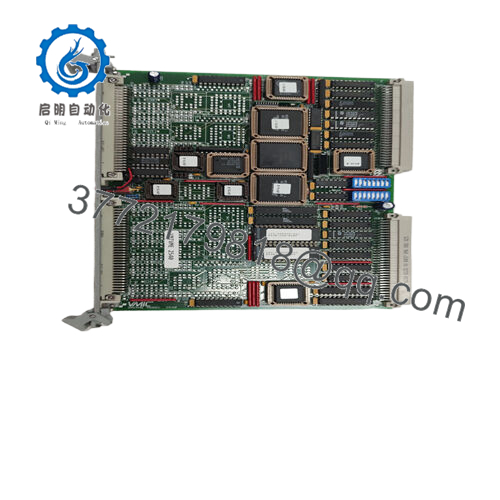

The GE IC693TCM302B is a high‑performance temperature control module for the GE Fanuc Series 90‑30 PLC family, providing eight thermocouple input channels and eight associated control outputs in a single slot. Functionally, it acts as an intelligent temperature controller board that plugs directly into the 90‑30 baseplate: it acquires low‑level temperature signals, executes closed‑loop PID algorithms, and drives outputs that typically control heaters, solid‑state relays, or contactors. Instead of handling every PID loop inside the main CPU, the GE IC693TCM302B performs much of the loop processing locally on the module, then exposes process variables, setpoints, and status bits to the PLC’s logic for coordination and supervision

Within the overall control architecture, the GE IC693TCM302B sits alongside standard discrete and analog I/O modules on the Series 90‑30 backplane, sharing configuration and diagnostics through the same programming environment. It is typically assigned a block of analog‑style registers for temperature readings and setpoints, plus discrete bits for loop status, alarms, and control states. This allows the main PLC program to handle recipe selection, interlocks, alarms, and operator interface functions while the module provides fast, consistent loop execution. The GE IC693TCM302B supports manual (open‑loop) and automatic (PID closed‑loop) modes, giving operators and engineers flexibility to switch between automatic temperature regulation and direct output control for startup, testing, or maintenance.

For system integrators and OEMs, the GE IC693TCM302B is positioned as a way to consolidate multiple single‑loop controllers into one Series 90‑30‑centric solution. It simplifies panel design by eliminating separate controller faces, reduces wiring runs between controllers and the PLC, and ensures that all temperature‑related data is natively available in the control program. This combination of integrated measurement, loop control, and Series 90‑30 compatibility makes the GE IC693TCM302B an attractive choice for multi‑zone heating and thermal process applications.

Key Technical Features & Functional Benefits

The GE IC693TCM302B is designed to control up to eight independent temperature zones, each with its own thermocouple input and associated control output, allowing a single module to manage a complete multi‑zone machine or skid. It supports common thermocouple types (such as J, K, T and others as defined in the module’s configuration), and some variants also support RTD inputs, giving flexibility to match sensor type to the application’s accuracy, range, and wiring distance requirements. Built‑in cold‑junction compensation and linearization help ensure that the temperature values delivered to the PLC and used for control are accurate over the specified range, reducing the need for external signal conditioning hardware.

Control‑wise, the GE IC693TCM302B offers both manual (open‑loop) and automatic PID closed‑loop modes, with parameters such as proportional band, integral time, derivative time, and output limits configured per channel. This enables fine tuning of each zone to match its thermal inertia and heating characteristics, which is critical when some zones are tightly coupled and others respond slowly. Outputs can be configured for time‑proportioned control of heaters through solid‑state relays or contactors, and the module can also support alarm limits, sensor fault detection, and safety‑related shutdown signals when configured correctly in the PLC logic. The result is tighter temperature control, reduced overshoot, and improved energy use versus simple on/off thermostatic approaches.

From a hardware perspective, the GE IC693TCM302B combines low‑level sensor inputs with robust, isolated outputs in a compact Series 90‑30 form factor. Thermocouple inputs are designed to accommodate small‑signal, low‑noise wiring practices, while the output side is rated for an 18 to 30 V DC control supply with a typical load current around 100 mA per point—well suited for driving solid‑state relay inputs or other intermediate power devices. This separation allows the module to sit in the same rack as standard digital and analog I/O while maintaining appropriate electrical isolation and noise immunity between the sensor side and the control side.

Reliability features of the GE IC693TCM302B include continuous monitoring for sensor faults (such as open thermocouple detection) and module‑level diagnostics that allow the PLC to detect and react to failures. Distributed control of the temperature loops on the module means that loop timing is less sensitive to variations in PLC scan time, which improves stability and repeatability under varying system load conditions. Combined with the long‑established Series 90‑30 hardware platform, these design choices make the GE IC693TCM302B a robust solution for thermal processes expected to run continuously over many years

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE IC693TCM302B |

| Brand | GE Fanuc / GE Intelligent Platforms, Series 90‑30 family |

| Product Type | Temperature control module (thermocouple / RTD based) |

| Number of Input Channels | 8 temperature inputs (thermocouple; some configurations support RTD) |

| Number of Control Outputs | 8 control outputs associated with the 8 input channels |

| Supported Input Types | Common thermocouple types (e.g., J, K, T; see manual for full list) |

| Control Modes | Manual (open‑loop) and automatic PID closed‑loop per channel |

| Output Voltage Range | 18 to 30 V DC control supply for outputs |

| Maximum Load Current | Approximately 100 mA per output point (for driving SSRs or interfaces) |

| Module Function | Performs local temperature measurement and control; presents setpoints, PVs, and status to PLC |

| Rack Compatibility | Installs in a single slot of a GE Series 90‑30 baseplate |

| Typical Weight | Around 0.66 kg (module only) |

| Typical Applications | Multi‑zone ovens, extruders, furnaces, environmental chambers, thermal skids |

Exact ranges, supported sensor types, and electrical ratings should be verified against the official GE/Emerson IC693TCM302 user manual and datasheet.

Related Modules or Compatible Units

GE IC693TCM302 – Base catalog version of the same temperature control module family; the GE IC693TCM302B is a later revision with similar form, fit, and function.

GE IC693ALG223 – Sixteen‑channel analog current input module often used alongside the GE IC693TCM302B to bring in non‑temperature process variables such as pressure or flow

GE IC693CPU364 – A common Series 90‑30 CPU that frequently runs applications using the GE IC693TCM302B for multi‑zone temperature control.

GE IC693MDL752 – DC output module used when higher‑power heater contactors or additional discrete control points are required in conjunction with the GE IC693TCM302B.

GE IC693PWR330 – Series 90‑30 power supply that provides the backplane power needed by the GE IC693TCM302B and associated I/O modules.

GE IC693CMM311 – Communications coprocessor module enabling higher‑level connectivity (such as SCADA or host systems) for systems that also rely on the GE IC693TCM302B for temperature control.

Installation Notes & Maintenance Best Practices

For best results, the GE IC693TCM302B should be installed in a Series 90‑30 rack location that allows clean routing of low‑level thermocouple wiring away from higher‑voltage and high‑current conductors. Thermocouple leads should be run using appropriate extension cable and polarity, with junctions and shields handled according to good instrumentation practice to avoid ground loops and noise pickup. The output side should be powered from a stable 18–30 V DC supply, fused and grounded per panel standards, with outputs typically driving solid‑state relay inputs or interposing devices rather than heaters directly. Careful channel‑to‑zone documentation and clear labeling of terminals make commissioning and later troubleshooting far easier, especially in systems using all eight zones.

During operation, maintaining the GE IC693TCM302B revolves around verifying sensor integrity, monitoring loop performance, and periodically reviewing PID parameters. Open‑circuit thermocouple detection and alarm bits should be included in the PLC program so that sensor failures or wiring faults result in safe, predictable actions. Maintenance teams should periodically check terminal tightness, look for signs of heat or corrosion at sensor junctions, and verify that readings remain consistent with portable reference instruments where process criticality demands it. When process conditions change—such as new product recipes or modified heating hardware—tuning of the module’s PID parameters may be required; best practice is to test such changes during controlled trials and document the final settings per zone so that the GE IC693TCM302B continues to deliver stable, repeatable thermal control.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626