Description

In industrial automation and process control environments, operators and engineers often struggle with basic or text-based interfaces that limit visualization of complex processes, making it harder to interpret trends, alarms, and system states quickly during normal operation or fault conditions. In facilities like manufacturing plants, utilities, or batch processing lines, where multiple variables need monitoring simultaneously—such as flow rates, temperatures, and equipment status—relying on alphanumeric displays or separate SCADA terminals can slow response times, increase operator error, and complicate training. This becomes particularly challenging in legacy Series 90-70 systems requiring graphical oversight without full migration to modern HMIs. The GE IC697GDC701 Graphics Display Coprocessor (GDC) addresses these needs directly within the Series 90-70 PLC family, providing a single-slot module that runs dedicated Graphics Display System (GDS) software for creating and displaying custom process graphics, trends, and dynamic screens. Engineered for high-reliability industrial automation, the GE IC697GDC701 enables rich graphical representations tied to real-time I/O signals, enhancing situational awareness in process control setups where clear, intuitive visualization is key to maintaining uptime and safety. Its integration into existing VME racks makes it essential for upgrades focusing on operator interface improvements without disrupting core control logic.

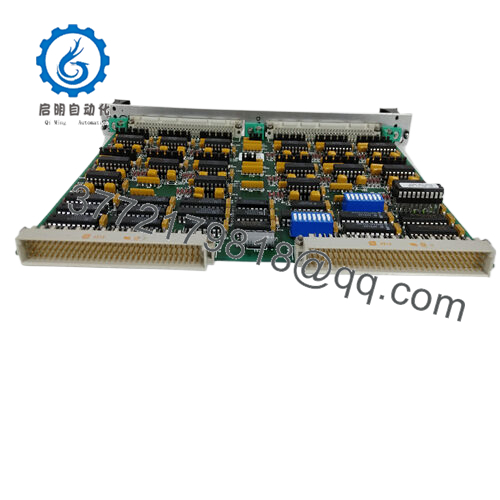

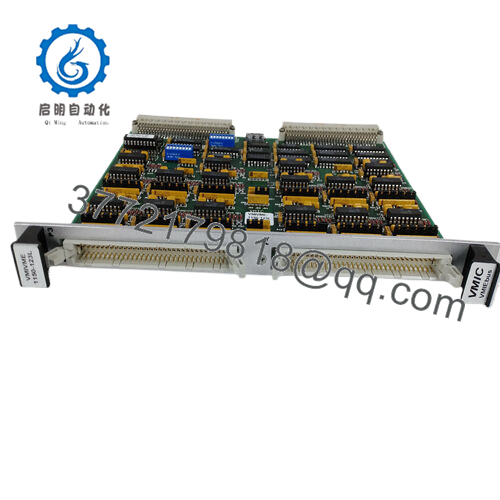

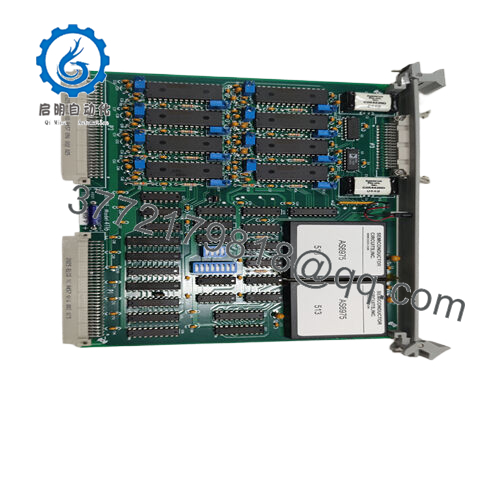

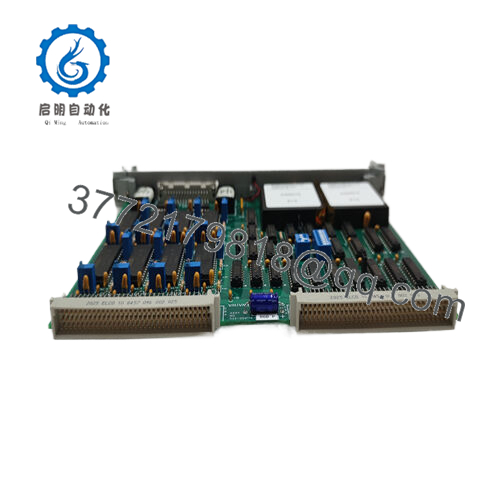

The GE IC697GDC701 functions as a dedicated coprocessor in the Series 90-70 architecture, occupying a single slot on the VME backplane to offload graphical processing from the main CPU. It runs IC640HWP77X GDS software, allowing development of color graphics, animations, and interactive screens that reflect live data from discrete and analog I/O points across local racks or Genius distributed networks. Positioned alongside the primary CPU and communication modules in the control layer, it communicates via the backplane for seamless access to PLC variables, while supporting serial ports for configuration uploads or external connections. Diagnostics include front-panel LEDs for module status, serial activity, and backplane communication, plus a pushbutton for resets. In a typical setup, the GE IC697GDC701 renders screens on connected monitors or panels, providing operators with graphical mimics, alarm lists, and historical trends without relying on higher-level systems, ensuring responsive visualization even in standalone or redundant configurations where protocol handling and signal reliability remain critical.

- IC697GDC701

- IC697GDC701

| Specification | Details |

|---|---|

| Model Number | IC697GDC701 |

| Brand | GE Fanuc (now Emerson) |

| Type | Graphics Display Coprocessor Module |

| Input Voltage | 5 V DC (from rack power supply) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Rack-mount (VME backplane, single slot) |

| Dimensions | Standard IC697 module (approx. 11.2 x 1.3 x 9.2 inches) |

| Weight | Approx. 1.8 kg |

| Interface/Bus | VME backplane, serial ports |

| Compliance | CE, UL, CSA (typical for series) |

| Supported Protocols | Compatible with Series 90-70 SNP/SNPX via backplane |

| Typical Power Draw | Approx. 15-20 W |

Choosing the GE IC697GDC701 brings graphical capabilities that enhance operator effectiveness in process control applications, where its dedicated processing ensures smooth rendering of complex screens without burdening the main CPU’s scan time. The module’s ability to handle dynamic updates—like color changes for alarms or animated flow indicators—delivers consistent performance in environments with frequent data changes, reducing misinterpretation and supporting faster decision-making. Battery-backed retention protects custom graphics during power cycles, minimizing reconfiguration needs and contributing to long-term reliability.

Engineered for integration ease, the GE IC697GDC701 lowers engineering overhead by using familiar GDS tools for screen development, allowing reuse of existing logic variables without extensive remapping. This results in sustained performance over years, with robust diagnostics that flag issues early and facilitate targeted maintenance, ultimately extending system life in demanding industrial settings.

The GE IC697GDC701 is frequently used in water treatment plants for graphical monitoring of filtration stages, pump status, and chemical levels, supporting continuous uptime in harsh, wet conditions with clear visual alarms for critical process control. In food and beverage manufacturing, it displays batch recipes, conveyor flows, and temperature profiles on custom screens, handling fast data cycles amid sanitary requirements. Power distribution facilities deploy it for substation overviews, showing breaker states and load trends in environments needing high-reliability visualization for rapid fault isolation.

IC697CPX935 – High-performance CPU often paired with GDC for larger graphical applications

IC697CPX772 – Mid-range CPU compatible in systems using the GDC for visualization

IC697CPX928 – 32-bit CPU alternative for enhanced processing alongside graphics

IC697CGR935 – Redundant CPU for high-availability setups with graphical oversight

IC697BEM731 – Genius I/O Bus Controller for distributed data feeding into GDC screens

IC697PCM711 – Programmable Coprocessor Module as a complementary option for additional tasks

IC697CMM711 – Communications Coprocessor for serial integration with display systems

IC697ADC701 – Alphanumeric Display Coprocessor as a text-based predecessor

Before adding the GE IC697GDC701 to a rack, confirm available slot outside of CPU/reserved positions, adequate power supply headroom (typically 5 V DC with margin for graphics load), and ventilation clearance since coprocessing can generate additional heat. Verify GDS software version compatibility with your programming environment and ensure a charged battery is installed for graphics retention.

Ongoing checks include monitoring the three front-panel LEDs—top for module health, lower for port and backplane activity—to spot communication or operational issues promptly. Periodically inspect serial connectors for firmness in vibrating settings, and test battery life yearly to safeguard custom screens. A simple reset via the onboard pushbutton can clear transient faults, and maintaining a configured spare supports quick replacement in graphics-critical operations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626