Description

In massive automotive paint shops, where robotic arms spray chassis at 100 units per hour, any HMI freeze risks overspray defects that scrap entire batches and trigger rework lines. Pulp and paper mills coordinating wet-end stock prep across 500-meter spans need touch interfaces that deliver crisp diagnostics amid steam and pulp dust, preventing fiber breaks that halt winders. Pharmaceutical filling lines demand intuitive screens for recipe tweaks, ensuring FDA-traceable changeovers without halting sterile flows. The GE IC752WTE001B enters these industrial automation arenas as a rugged 15-inch touchscreen workstation from GE’s QuickPanel+ series, providing operators with real-time visibility into PACSystems logic and I/O status for swift interventions. Used in industrial automation for HMI/SCADA front-ends, it mounts overhead or panel-style to centralize control in noisy control systems.

Offshore drilling platforms equip the GE IC752WTE001B for driller consoles, rendering mud pump pressures and BOP status through fogged visors. Food extruders use it to visualize twin-screw profiles, adjusting shear rates on the fly to nail texture specs. Tire curing presses lean on its multi-window views for mold cycle timing, dodging under-vulcanized rejects. Applicable in control systems from bottling carousels to metal stamping, this workstation processes SVG graphics and historian trends, empowering shifts to correlate alarms with process curves. Maintenance crews favor it for built-in recipe editors that streamline batch swaps, cutting setup from hours to minutes in high-mix environments.

Renewable solar inverters benefit from the GE IC752WTE001B‘s Ethernet trending of MPPT curves, spotting string faults before yield drops. Textile winders deploy it for tension profiling across doffer rolls, with trend zooms revealing yarn breaks early. By delivering operator-centric insights in industrial automation, it bridges the human gap, fostering proactive tweaks that lift OEE across shifts.

Product Introduction & Positioning

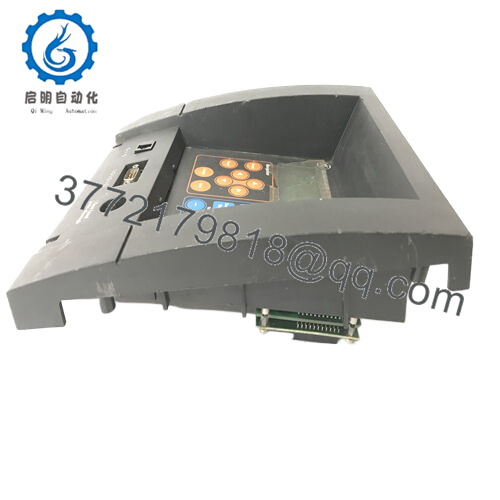

The GE IC752WTE001B is a versatile 15-inch widescreen touchscreen HMI terminal within GE Fanuc’s (now Emerson) QuickDesigner ecosystem, acting as the visual command center for RX3i, VersaMax, and 90-70 PLCs in distributed automation networks. Featuring a 1024×768 TFT LCD with 65K colors and resistive analog touch, it hosts up to 400MB of project space for WinCC-like screens, trends, and alarms downloadable via Ethernet or USB. In rack or standalone mounts, the GE IC752WTE001B polls controllers over Proficy protocols, mapping tags to dynamic objects for live mimicry of P&IDs or drive status.

Positioned for mid-sized panels, the GE IC752WTE001B embeds dual Ethernet for redundancy alongside serial RS-232/422/485 ports supporting Modbus RTU/TCP and SNP—perfect for daisy-chaining legacy drops. Operators gain from gesture-enabled navigation and PDF viewers for SOPs, while integrators leverage IEC 61131 scripting for custom logic like data loggers. Its value lies in seamless Proficy Machine Edition ties, auto-generating screens from ladder rungs to accelerate commissioning.

For system designers, the GE IC752WTE001B scales via VNC remote access, fitting hybrid MES floors where HMIs feed downtime analytics. Native support for barcodes and soft keyboards positions QuickPanel+ as a cost-effective bridge to modern web HMIs without full overhauls.

Key Technical Features & Functional Benefits

Shift techs count on the GE IC752WTE001B‘s sunlight-readable brightness (400 nits) and anti-glare bezel to cut glare in brightly lit bays, with 5-wire touch enduring 10 million taps for glove-friendly inputs. Dual-core processing renders 100+ trends at 60 FPS, buffering 1GB logs to CFast cards for post-shift audits—no PC handhelds needed. Isolated power inputs fend off surges common in motor starter cabinets, maintaining uptime through weld spatter or washdowns.

Footprint-friendly at 400x300mm, the GE IC752WTE001B panels flush with NEMA 4/12/IP65 ratings, drawing 30W at 24VDC to run fanless from PLC PSUs. USB 2.0 ports enable recipe swaps or firmware flashes on-site, while dual NICs load-balance OPC UA traffic to reduce latency in Ethernet/IP spines. Audio buzzers cue alarms audibly over conveyor roar, and real-time clocks sync via NTP for timestamped events.

Durability extends via solid-state design with MTBF over 100K hours, conformal-coated boards shrugging 95% humidity. Scripting lets users embed C-like functions for calculated fields like efficiency KPIs, with password tiers locking recipes. Field upgrades via SD slots keep it patched against vulns, minimizing refresh cycles in long-lived plants.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE IC752WTE001B |

| Brand | GE Fanuc (Emerson) |

| Type | 15″ Widescreen Touch HMI |

| Power Supply | 24 VDC (18-30 V), 1.25 A max |

| Operating Temperature | 0°C to 55°C |

| Mounting | Panel (3-10mm thick), 100mm depth |

| Dimensions | 383 x 296 x 94 mm (W x H x D) |

| Weight | 6.5 kg |

| Interfaces | 2x Ethernet 10/100, 2x RS232/422/485, 2x USB 2.0 |

| Certifications | UL, CE, cULus, IP65 front |

| Cooling | Fanless, passive |

| Environmental Rating | NEMA 4/12 front, 0-95% RH |

- IC752WTE001B

- IC752WTE001B

Related Modules or Compatible Units

IC752WTD010 – 10.1″ compact sibling for space-crunched cabinets pairing with GE IC752WTE001B in multi-station setups.

IC752WTF001 – 19″ larger display extending GE IC752WTE001B views for supervisor consoles.

IC695CPU315 – RX3i CPU that the GE IC752WTE001B polls for high-speed tag exchanges.

90-30 IC693CPU – Legacy PLC compatible via serial for brownfield HMIs with GE IC752WTE001B.

IC200UHX – VersaMax PROFINET scanner integrating seamlessly under GE IC752WTE001B oversight.

PProficy HMI/CNC – Software suite for screen design feeding GE IC752WTE001B projects.

IC695ETM – Ethernet module boosting RX3i comms to GE IC752WTE001B clients.

Installation Notes & Maintenance Best Practices

Cut a precise 367x272mm hole for flush GE IC752WTE001B panel fit, torquing clamps to 1.2 Nm and sealing gaskets against dust ingress—test IP65 spray post-mount. Route Ethernet Cat5e under ferrite beads to clamp EMI from VFDs nearby; bond frame ground to cabinet stud at 1 ohm max. Power from isolated 24V rails, fusing at 2A slow-blow, and preload project via Ethernet TFTP before sealing. Verify touch calibration via setup menu, adjusting for parallax in thick bezels. Avoid direct sunlight on LCD; angle for 30-60° viewing cones.

Wipe touchscreen monthly with microfiber and IPA-damp cloths, steering clear of abrasives that pit resistive layers. Quarterly, export diagnostic logs via USB to scan for touch ghosting or memory leaks—reset via %SW50 if drifts exceed 2%. Firmware checks biannually through Proficy View pull latest patches, staging offline first. Cycle power yearly to refresh flash, monitoring bezel LEDs for boot faults. Backup recipes to CFast every shift end, rotating media to dodge wearout in vibration-heavy spots.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626