Description

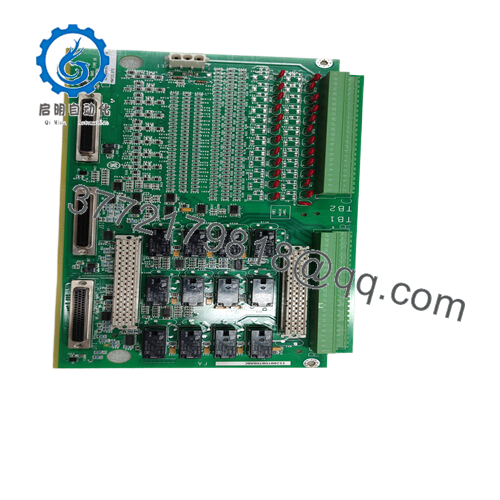

Product Model: GE IS200ICIAH1ABB

Product Brand: GE Industrial Solutions

Product Series: Mark VI IS200 Series

Product Features:

• Designed for precision control and high-reliability industrial automation

• Compatible with GE Mark VI / Mark VIe turbine and control systems

• Robust electronic interface for process logic and I/O integration

• Field-proven performance with simplified diagnostics and serviceability

Technical Specifications

| Specification | Detail |

|---|---|

| Product Model | GE IS200ICIAH1ABB |

| Series | Mark VI IS200 Series |

| Function | I/O Interface / Control Logic Board |

| Backplane Compatibility | GE Mark VI / Mark VIe backplanes |

| Signal Support | Digital Inputs/Outputs (field logic) |

| Power Requirements | Standard rack power (per system spec) |

| Operating Temp | Industrial range (0°C to 60°C typical) |

| Mounting | DIN/Backplane slot |

| Diagnostics | Signal status flags and health indicators |

| EMC Compliance | Industrial EMC/EMI design |

| Connectors | Keyed edge/backplane interfaces |

| Serviceability | Modular field replaceable |

- IS200ICIAH1ABB

Product Role & System Fit

At its core, the GE IS200ICIAH1ABB is a control interface assembly that bridges physical I/O with logical process control. In a typical setup, field-level sensors — such as temperature probes, pressure transmitters, limit switches, and RPM pickups — feed signals into I/O modules. The module then conditions and relays these signals into the larger control processor, such as a Mark VI or DCS controller. Conversely, control outputs from logic decisions are translated through this board into actuator drives, relays, or alarm annunciators.

This part’s role in a Mark VI IS200 Series rack is indispensable: it ensures that field events are captured accurately and routed correctly. In systems where timing and sequence are critical — think turbine start-up/shut-down sequences or emergency trip logic — the board’s deterministic behavior under all conditions contributes directly to operator confidence.

Integration engineers value the GE IS200ICIAH1ABB because it doesn’t require extensive custom firmware flashes or complex configuration scripts. It adheres to standardized pinouts and communicates over familiar backplane channels, reducing project lead times. For retrofit projects where original OEM boards are obsolete or long-lead, this module often serves as a compatible drop-in or close alternative with minimal rewiring.

Its fit within redundant architectures also matters. In high-availability plants, redundant controller strings ensure business continuity. The GE IS200ICIAH1ABB can be deployed in both primary and backup channels, providing consistent performance that supports automatic failover without signal loss or logic ambiguity.

Maintenance teams also note that the board’s footprint and mounting options align with typical rack designs in industrial control cabinets. This reduces the engineering overhead during design revisions and simplifies spares inventory — a single part number can address multiple slot requirements in legacy and newer builds.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626