Description

In turbine and process plants, discrete signals from field devices drive every trip, permissive, and alarm decision. Operators need reliable status from pressure switches, limit switches, and auxiliary contacts to keep steam turbines, gas turbines, and balance-of-plant equipment running safely. The GE IS200STCIH6AED is typically used in this layer of the control system, where clean, isolated contact inputs feed into a GE Mark VI or similar control platform used in industrial automation and applicable in control systems that demand deterministic response and high availability. It sits between rugged field wiring and the controller, helping engineers trust that every start/stop command, protection signal, and interlock is captured accurately.

In a combined-cycle facility, a single false contact input from a limit switch can trigger nuisance trips or, worse, fail to trip when required. The GE IS200STCIH6AED mitigates these risks by conditioning and isolating contact inputs, allowing logic in the turbine control panel to process clean, debounced signals. In refineries, petrochemical units, and pipeline stations, it supports 24 V DC contact circuits commonly used for safety chains, motor control centers, and valve position feedback. For plants migrating from older relay-based schemes, this module allows them to bring legacy dry contacts into a modern digital I/O architecture without reworking every field device. The design lends itself to dense marshalling, with multiple channels brought neatly into a control cabinet, simplifying wiring routes and documentation. Over time, that translates into easier troubleshooting and shorter outages, which is exactly what maintenance and reliability teams push for.

Product introduction and positioning

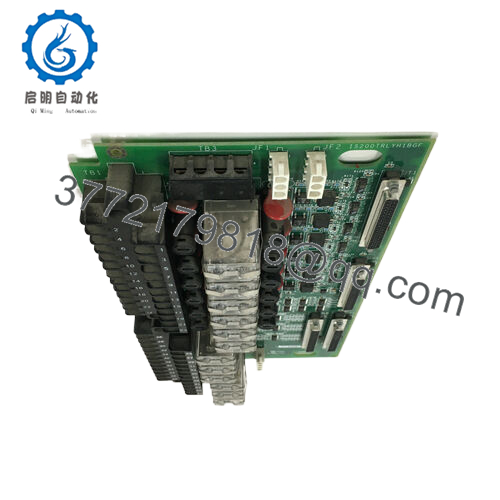

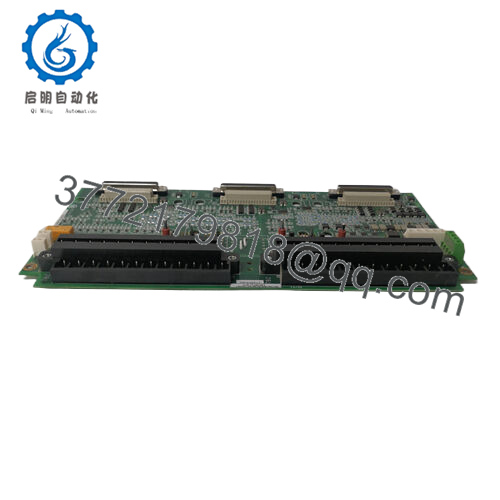

The GE IS200STCIH6AED is best understood as a simplex contact input terminal board or digital input module designed for use within GE turbine and process control systems, most notably the Mark VI family. Its core role is to accept a set of discrete 24 V DC signals from field contacts and present them in a form that the controller’s I/O subsystem can safely read and diagnose. Engineers will often treat it as the primary interface for dry contacts scattered around the turbine package, auxiliary skids, and balance-of-plant equipment.

Within the architecture of a control system, the GE IS200STCIH6AED typically resides in an I/O cabinet or panel, connected on one side to terminal blocks and field wiring, and on the other side to controller or data acquisition modules. It acts as the electrical and functional boundary between noisy plant environments and the relatively sensitive logic hardware. That placement in the signal chain makes it a key part of both functional safety and operational reliability strategies. Because it is tailored to the voltage range and signal characteristics common in GE’s Mark VI ecosystem, integrators can drop it into new builds or retrofits with minimal engineering effort, aligning it with standard 24 V DC control practices. For project managers and plant engineers, the value lies in the combination of recognized GE quality, predictable behavior under harsh temperatures, and proven compatibility with turbine control logic and diagnostics.

Key technical features and functional benefits

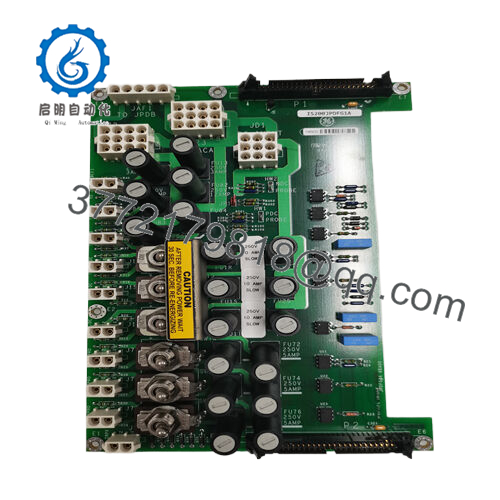

At the functional level, the GE IS200STCIH6AED focuses on reliable digital input performance rather than raw processing power. It supports a defined DC voltage range—commonly 24 V DC with tolerance around ±15% or within a broader 9–30 V DC window—so that even modest variations in supply do not compromise the recognition of “on” and “off” states. This tolerance becomes critical when long cable runs and field wiring resistance lead to small drops in voltage at the point of measurement. By keeping its thresholds well aligned with industrial practice, the board reduces spurious transitions that can plague trip and alarm logic.

Hardware design on the GE IS200STCIH6AED reflects the reality of power and turbine facilities. Channels are arranged to simplify marshalling from terminal strips, with clear labeling and separation that help technicians quickly identify and trace signals during commissioning or fault-finding. The board is built for extended operating temperatures, often from about -40°C up to +70 or +85°C depending on the exact implementation, allowing it to sit inside cabinets in climates ranging from cold outdoor installations to warm turbine enclosures. This kind of temperature resilience improves long-term reliability, especially where cooling is limited and ambient temperatures fluctuate with plant load.

Compatibility is another strength for the GE IS200STCIH6AED. It integrates into GE control systems, so signal conditioning, channel diagnostics, and configuration are handled in a way that matches the rest of the Mark VI hardware family. That means an integrator can treat it as part of a known building block set when laying out new I/O segments or expanding existing nodes. Over the life of the plant, this compatibility helps with spare parts stocking, training, and documentation. Engineers can standardize around a few board types, improving maintainability and reducing the risk of misapplication.

From a reliability standpoint, the GE IS200STCIH6AED is designed for long service life with minimal intervention. Industrial-grade components and attention to isolation and input protection help it tolerate electrical noise, transient spikes, and occasional wiring issues better than generic I/O hardware. For operators, this translates into fewer unexplained input failures and a lower risk that a critical contact signal disappears during upset events. In plants where shutdown logic depends heavily on correct contact states, that is a very tangible benefit.

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | GE IS200STCIH6AED |

| Brand | General Electric (GE) |

| Type | Simplex contact input terminal board / digital input module |

| System Platform | GE Mark VI or related turbine and process control systems |

| Nominal Input Voltage | 24 V direct current (±15 percent typical) |

| Supported Voltage Range | Approximately 9–30 V direct current for contact inputs |

| Number of Input Channels | 16 digital input channels (typical configuration) |

| Operating Temperature Range | -40°C to +85°C (cabinet or panel mounted) |

| Power Supply Source | Supplied from associated control system power distribution |

| Mounting | Panel or control cabinet mounting via hardware and terminal connections |

| Isolation | Channel-to-channel and channel-to-system isolation for industrial environments |

| Typical Applications | Turbine contact inputs, interlocks, permissives, and status monitoring |

- IS200STCIH6AED

Related modules or compatible units

GE IS200STCIH6A – A closely related contact input terminal board variant used in similar Mark VI applications, with comparable channel counts and voltage handling.

GE IS200STCIS6AED – Another Mark VI contact input board version, often used where different wiring or redundancy arrangements are required.

GE IS200SRLYH1A – Relay output board commonly paired with contact input modules to drive trips, solenoids, and motor starters in the same control cabinet.

GE IS200TRLYH1A – Trip relay board providing high-integrity outputs that complement digital inputs used for protection schemes.

GE IS200SPIDG1A – Control or processor-related module that interprets the signals from input boards within the turbine control system.

GE IS200VTURH1B – Turbine-related module that works in concert with discrete input boards to execute speed and protection logic.

Installation notes and maintenance best practices

When planning installation of the GE IS200STCIH6AED, engineers should first confirm that panel space, wiring duct, and cable entry are sized for the full count of field contacts, including spare channels for future expansion. Good practice is to segregate contact input wiring from high-voltage or high-current cabling to minimize induced noise, especially in turbine halls where starters and large drives operate nearby. Grounding and shielding of multi-core cables should match site standards, typically with shield terminations at the cabinet end to provide a clean reference for the board and the control system. It is also worth verifying that the 24 V DC supply and any auxiliary power are stable and sized with margin, since under-voltage conditions can degrade the interpretation of input states.

Maintenance of the GE IS200STCIH6AED tends to be straightforward but important. Periodic visual inspections should look for discoloration, loose terminal screws, and any signs of contamination from dust or moisture inside the cabinet. Plants often schedule annual or semi-annual checks to validate that key safety and trip contacts are being correctly detected by the control system, using simulated contact closures or loop checks. If the system offers diagnostic counters or status for each input channel, maintenance teams can review these during planned outages to spot intermittent behavior that might indicate wiring or contact problems. Keeping documentation of channel assignments and ensuring labels match the actual wiring in the field greatly speeds troubleshooting when a signal behaves unexpectedly.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626