Description

In modern power and process plants, high-speed communication between controllers, I/O, and supervisory systems is just as critical as the field signals themselves. When a turbine trips, a generator synchronizes, or a boiler sequence starts, controllers must share status, setpoints, and diagnostics across redundant networks with very low latency. The GE IS200TPR0S1CBB is used in exactly this layer of the architecture: it serves as a powerful processor and communication module within the GE Mark VIe series, used in industrial automation and applicable in control systems where deterministic response and integrated data handling are mandatory. In combined-cycle plants, large gas turbines, and auxiliary process trains, it helps coordinate logic execution, network traffic, and interface tasks that link local I/O to plant-wide systems.

Think of a Mark VIe cabinet supervising multiple turbine sections and balance-of-plant packages. The GE IS200TPR0S1CBB provides the computing core that executes application code, manages network interfaces, and supports diagnostics, while other boards focus on pure I/O termination or power conditioning. When operators request changes from the HMI or when the DCS queries performance data, this module handles those transactions and ensures they are synchronized with the real-time control loops. In retrofit projects, it is often selected to modernize a control node without replacing all downstream I/O, allowing plants to step up to newer processing technology while protecting their existing investment in wiring and terminations. For integrators and engineers, that combination—modern processing capability, industrial reliability, and Mark VIe compatibility—makes the GE IS200TPR0S1CBB a central building block whenever they design, upgrade, or expand turbine and process control systems.

Product introduction and positioning

The GE IS200TPR0S1CBB is a high-performance processor module designed for the GE Mark VIe control system platform. Within that ecosystem, it functions as a main controller or processing board, hosting the application logic that governs turbine operation, auxiliary equipment, and critical protection functions. It is not just a simple interface card; it is the computational heart of a Mark VIe node, where sequence logic, control algorithms, and data handling routines all run in tightly controlled cycles.

In the architecture of a Mark VIe system, the GE IS200TPR0S1CBB typically resides in the main rack or controller section, linked to I/O packs, network switches, and higher-level systems such as plant DCS or SCADA. It may support multiple Ethernet interfaces for segmented networks, along with redundancy strategies that allow warm or hot standby controllers to take over if a fault occurs. This positioning gives it direct influence over both real-time control and data exchange, enabling smooth coordination between turbine subsystems and external systems like historian servers and remote monitoring centers. For engineers and integrators, the value of the GE IS200TPR0S1CBB lies in its ability to deliver strong processing performance, comprehensive communication options, and proven integration within the Mark VIe framework—all wrapped in a form factor and design approach that matches plant expectations for long-term availability and maintainability.

Key technical features and functional benefits

From a functional performance standpoint, the GE IS200TPR0S1CBB is built around a modern multi-core processor platform (commonly an embedded AMD G-series or comparable industrial CPU), giving it enough computing headroom to run complex control strategies, high-speed monitoring, and extensive diagnostics in parallel. This is particularly important in turbines and large rotating equipment, where vibration monitoring, protection logic, and performance optimization algorithms all compete for computing resources. With a robust processor at its core, the module can maintain tight scan times even as applications grow in size and sophistication, helping plants implement more advanced control schemes without sacrificing responsiveness.

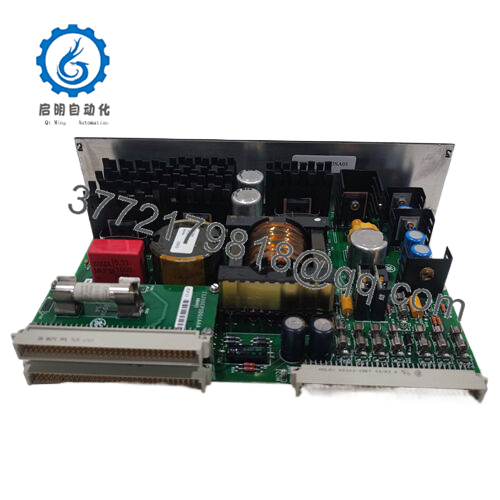

The hardware design of the GE IS200TPR0S1CBB reflects typical Mark VIe priorities: rugged construction, secure mounting, and effective thermal management. The board is usually installed in a well-defined slot with positive retention, designed to withstand cabinet vibration and thermal cycling over years of operation. Components are laid out to support efficient heat dissipation, often with conduction paths to the rack or controlled airflow channels in the cabinet. This reduces the risk of hotspots and extends the life of critical electronic components. The compact footprint also supports dense control configurations, allowing multiple controllers or redundant pairs to sit side by side in a single panel.

Compatibility is a major strength. The GE IS200TPR0S1CBB integrates seamlessly with other Mark VIe modules, including I/O packs, communication interfaces, and redundant controllers. It typically supports multiple industrial Ethernet ports, enabling segmented control networks, dedicated maintenance ports, and secure paths to higher-level systems. Standard field protocols and Mark VIe-specific networking schemes allow it to talk natively with existing equipment, simplifying both commissioning and later expansions. For plants that already rely on GE controls, this means the module can be dropped into established architectures with minimal re-engineering.

Long-term reliability is another core benefit. The GE IS200TPR0S1CBB is designed for continuous 24/7 operation in demanding environments, using industrial-grade components, conservative derating, and robust firmware strategies. Built-in diagnostics and status indicators typically monitor internal temperatures, network health, and application states, enabling predictive maintenance and fast fault isolation. In many installations, the module participates in redundant schemes where another controller can take over if a severe fault is detected, further reducing the risk of unplanned downtime. For operators and maintenance teams, this translates into high availability and a clear path to managing lifecycle risks over many years of service.

- IS200TPR0S1CBB

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | GE IS200TPR0S1CBB |

| Brand | General Electric (GE) |

| Type | Processor / controller module for turbine and process control |

| System Platform | GE Mark VIe control system |

| Processor | Industrial multi-core embedded CPU (such as AMD G-series class) |

| Typical Processor Frequency | Approximately 1.0–1.5 gigahertz (application dependent) |

| Main Functions | Application logic execution, communications, diagnostics |

| Power Supply | Supplied via Mark VIe rack backplane direct current feed |

| Operating Temperature Range | Approximately -20°C to +60°C in a ventilated control cabinet |

| Mounting | Rack-mounted in dedicated Mark VIe controller slot |

| Network Interfaces | Multiple Ethernet ports for control, maintenance, and data links |

| Typical Applications | Gas and steam turbine control, balance-of-plant, process control |

Related modules or compatible units

GE IS200STCIH6AED – Digital input / contact input module often used in the same Mark VIe systems to bring in discrete turbine and process signals.

GE IS200ERBPG1A – Exciter regulator backplane associated with generator excitation systems that can be commanded from Mark VIe controllers.

GE IS200SPIDG1A – Control or processor-related module that can work alongside the GE IS200TPR0S1CBB in complex control nodes.

GE IS200STCIS6AED – Alternate contact input board variant that pairs with processor modules in distributed I/O architectures.

GE IS200SRLYH1A – Relay output module used to actuate trips, solenoids, and contactors driven by logic running on the GE IS200TPR0S1CBB.

GE IS200VTURH1B – Turbine-specific module that interacts with processor cards to implement speed and protection logic.

Installation notes and maintenance best practices

Before installing the GE IS200TPR0S1CBB, engineers should verify that the Mark VIe rack or cabinet has appropriate power capacity, ventilation, and grounding for another high-performance controller. Cabinet layout should allow for sufficient airflow across the module, avoiding obstruction by cable bundles or poorly placed ducting. It is good practice to ensure that all backplane connectors are clean and undamaged, and that electrostatic discharge precautions are followed while handling the board. Network design should be reviewed early: assign dedicated ports for control networks, maintenance access, and external interfaces, and document IP addressing and VLAN arrangements to avoid confusion during commissioning.

Maintenance of the GE IS200TPR0S1CBB centers on monitoring diagnostics and preserving a clean, thermally stable environment. Periodic visual inspections should look for signs of discoloration, loose retention hardware, or accumulated dust in the cabinet that could impede cooling. Many Mark VIe installations schedule regular checks of controller health, including CPU load, memory usage, and internal temperature trends, using the system’s engineering tools. Firmware and application software should be managed under clear revision control, with backups kept current so that a replacement unit can be commissioned quickly if needed. When a controller swap is required, technicians should follow documented shutdown and restart procedures to ensure redundancy is preserved and to avoid unexpected trips or logic resets.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626