Description

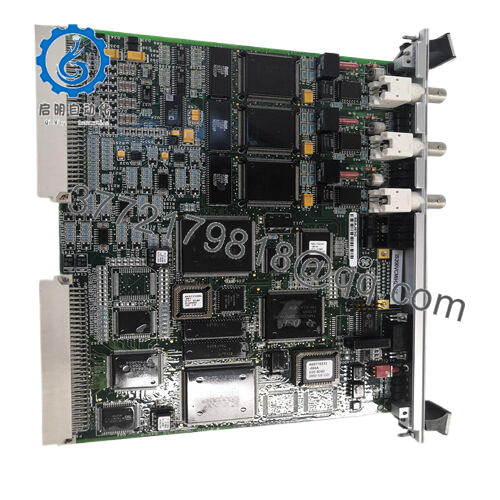

Product Model: GE IS200VTURH2BAC

Product Brand: General Electric (GE Fanuc)

Product Series: Mark VI Speedtronic Control Series

Product Features:

- Interface module for turbine vibration transducer signals

- Converts and conditions analog vibration data for Mark VI DCS

- Supports real-time monitoring and overspeed/condition protection

- Designed for rugged industrial environments and legacy control systems

- IS200VTURH2BAC

- IS200VTURH2BAC

Technical Specifications

| Specification | Description |

|---|---|

| Manufacturer | General Electric (GE Fanuc) |

| Product Model | GE IS200VTURH2BAC |

| Series | Mark VI Speedtronic Control System |

| Module Type | Vibration Transducer Interface Module |

| Function | Interface/aggregration of analog vibration sensor signals |

| Analog Inputs | Multiple channels for transducer inputs (varies by configuration) |

| Signal Conditioning | Preamplification, filtering, isolation circuit |

| Rack Interface | Mark VI backplane slot connection |

| Integration | Real-time data to Mark VI controller logic |

| Environment | Industrial turbine halls and power plant control cabinets |

| Protection | Designed for robust vibration, electrical noise tolerance |

| Typical Use | Vibration monitoring and protection systems |

Product Role & System Fit

The GE IS200VTURH2BAC is not a general-purpose I/O card; it is a specialized interface module designed for turbine vibration transducers within the Mark VI Speedtronic distributed control system. It accepts analog vibration inputs—typically sourced from accelerometers or similar sensors mounted on turbine bearings—and conditions those signals into usable data streams that the turbine controller can process for protection and diagnostic purposes.

While other GE Mark VI modules handle functions such as speed measurement, overspeed protection, or primary trip logic, this module’s focus is vibration monitoring—a key parameter in detecting mechanical imbalances, bearing wear, rotor bowing, and other early-stage failure modes. Integrating vibration data early into the control logic gives operators an actionable view of machine health and allows the central controller to make informed decisions about shutdowns, alarms, or load adjustments.

In a typical control rack, GE IS200VTURH2BAC occupies a defined slot within the modular backplane, interfacing directly with the Mark VI system’s communication bus. From here, it feeds conditioned data into the main controller logic, where algorithms can interpret trends and trigger protective actions if thresholds are exceeded. This level of integration—which avoids ad hoc signal conditioning or external preprocessing boxes—simplifies system architecture and reduces potential points of failure.

This placement and function underscore the importance of accurate installation and structured system documentation. Control engineers designing or maintaining Mark VI racks must plan for this module in the overall logic chain that supports turbine protection, ensuring that its outputs are included in alarm sequences, trending displays, and diagnostic logs used routinely during operation and outage analysis.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626