Description

In legacy VMEbus-based industrial automation and control systems, generating precise analog control signals across numerous channels while maintaining signal integrity and minimizing noise interference poses ongoing difficulties for engineers. Systems often suffer from limited output density, requiring multiple boards that increase crate space, wiring complexity, and potential points of failure—especially in applications demanding simultaneous updates to actuators like valves, positioners, or variable speed drives. This becomes critical in distributed process control environments where inaccurate or drifting analog outputs can lead to inconsistent performance, product quality issues, or safety concerns in continuous operations. The GE VMIVME-4140 addresses these challenges as a high-density 32-channel 12-bit analog output board, delivering reliable voltage signals with built-in calibration for sustained accuracy in industrial automation.

The GE VMIVME-4140 proves essential in scenarios requiring high channel counts with channel-to-channel isolation to prevent crosstalk, such as multi-loop control in large-scale testing rigs or when retrofitting older VME systems for expanded I/O without major redesigns. It supports offline testing capabilities, allowing disconnection from field wiring for safe validation, and excels in high-reliability industrial automation tasks involving precise setpoint control under electrical noise or vibration. Common in defense, simulation, and process control setups, the GE VMIVME-4140 ensures stable analog outputs, reducing calibration downtime and enhancing overall system reliability.

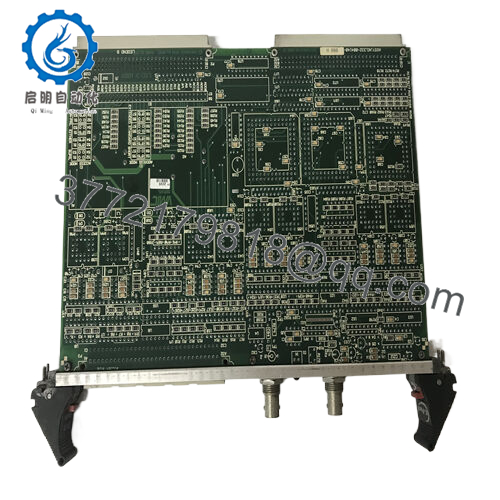

The GE VMIVME-4140 functions as a dedicated analog output module in the VMEbus architecture, occupying a single 6U slot and providing 32 independent channels via discrete wiring or transition panels. It converts digital values from the VME master (typically a single-board computer or controller) into analog voltages using individual 12-bit DACs per channel, supporting simultaneous or sequential updates.

Positioned in the I/O subsystem of the automation stack, it interfaces directly over the VME backplane in A16/A24 address modes, with jumper-configurable base addressing for flexible system integration. Outputs route through front-panel or P2 connectors, often paired with transition modules for field termination. The board includes autocalibration routines triggered by software or reset, plus built-in self-test diagnostics accessible via VME reads, aiding fault isolation without external tools. While not supporting advanced fieldbus protocols natively, the GE VMIVME-4140 integrates reliably in deterministic VME environments, offering low-latency updates suitable for real-time process control.

| Specification | Details |

|---|---|

| Model Number | VMIVME-4140 |

| Brand | GE Fanuc (Abaco Systems) |

| Type | 32-Channel Analog Output Board |

| Input Voltage | +5V DC (from VME backplane) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | 6U VMEbus Slot |

| Dimensions | Standard 6U VME (233mm x 160mm) |

| Weight | Approx. 0.7 kg |

| Interface/Bus | VMEbus A16/A24:D16, Discrete Wire or Transition Panel |

| Compliance | CE, UL (typical for series) |

| Supported Protocols | N/A (VME direct access) |

| Typical Power Draw | 7.5W (1.5A at +5V) |

- VMIVME-4140

- VMIVME-4140

Choosing the GE VMIVME-4140 brings engineered density and precision to analog output tasks, where dedicated DACs per channel ensure minimal settling time and consistent accuracy across all outputs, even under full load variations. This translates to reliable long-term performance in multi-actuator systems, with software-selectable ranges adapting to diverse field requirements without hardware changes.

The board’s channel isolation and autocalibration features reduce engineering overhead by simplifying commissioning and ongoing validation—outputs hold calibration over temperature swings, lowering drift-related adjustments. In practice, offline testing support enhances maintenance efficiency, allowing bench checks without disrupting plant wiring. The GE VMIVME-4140 also provides robust protection against transients, contributing to system resilience in noisy industrial settings.

Overall, its high channel count in a single slot optimizes crate utilization, delivering value through reduced spares inventory and easier scalability for expanding control loops.

The GE VMIVME-4140 finds frequent use in aerospace and defense simulation systems, driving multiple hydraulic or pneumatic actuators for flight surface control under harsh vibration and requiring critical system uptime with precise, synchronized outputs.

In process industries like chemical or pharmaceutical plants, it controls valve positioners and variable drives in multi-loop setups, ensuring stable operation in continuous processes amid electrical noise. Test and measurement rigs in automotive or energy sectors deploy it for high-density signal generation in endurance testing, supporting fast update cycles for dynamic load simulation in demanding environments.

VMIVME-4150 – Isolated 12-channel variant with voltage/current options for higher common-mode rejection

VMIVME-4120 – 16-channel high-drive analog output board for denser current sourcing

VMIVME-4132 – Companion 32-channel analog output with similar architecture

VMIVME-3123 – High-throughput analog input module often paired for closed-loop applications

VMIVME-4100 – Lower-density 16-channel digital-to-analog alternative

VMIVME-4514 – Scanning analog I/O board for mixed input/output needs

VMIACC-BT10 – Transition panel accessory for field wiring

Before installing the GE VMIVME-4140, confirm VME crate power capacity accommodates the 7.5W draw and verify base address jumpers avoid conflicts with other boards—reference the address map in your system controller. Check output range settings match field devices and prepare appropriate cabling or transition modules; ensure forced-air cooling aligns with the board’s thermal needs in densely populated crates.

Maintenance typically involves periodic review of calibration status via software commands or VME diagnostics, along with visual inspection of connectors for secure mating in vibratory environments. Monitor front-panel LEDs for fault indications post-reset, and perform autocalibration routines annually or after significant temperature excursions. Keep dust from accumulating on the board to maintain thermal performance, and log any offset drifts for trend analysis.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626