Description

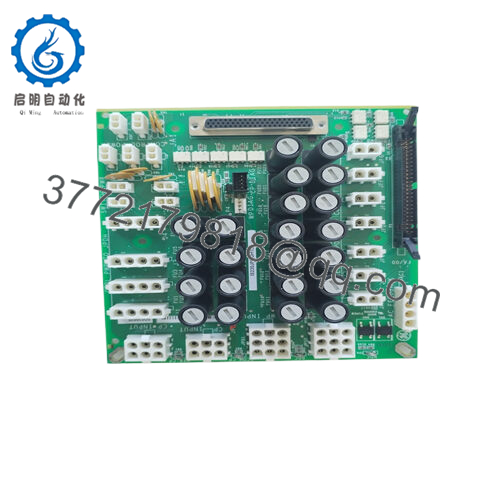

Product Model: IS230TVBAH2A

Product Brand: GE (General Electric)

Product Series: Mark VIe I/O Module Family

Product Features:

• Compact input/output interface module for industrial automation applications

• Designed for GE Mark VIe distributed control and turbine systems

• Supports reliable field signal termination and relay integration

• Built to endure industrial environments with vibration and temperature stresses

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Model | IS230TVBAH2A |

| Manufacturer | GE (General Electric) |

| Series | Mark VIe I/O Module |

| Module Type | Input/Output Interface / Terminal Board |

| System Compatibility | GE Mark VIe automation platforms |

| I/O Packs | Multiple (discrete/relay) |

| Relays Count | Typically 12 (varies by revision) |

| Terminal Blocks | 2 (TB1 and TB2) |

| Field Wiring Interface | Industrial terminal connectors |

| Environmental Design | Industrial grade for control cabinets |

| Vibration Tolerance | Engineered for moderate vibration |

| Mounting Style | Rack or panel integration |

| Typical Use Cases | Turbine control, generator automation, field signal interfacing |

- IS230TVBAH2A

Technical Features & Benefits

The IS230TVBAH2A is fundamentally an advanced input/output interface module engineered for integration with GE Mark VIe control platforms. Although full manufacturer specs are not broadly published online, available documentation and typical Mark VIe system conventions indicate several key attributes that make this board valuable in industrial automation.

Structurally, the module includes multiple terminal connections and relay interfaces to manage discrete inputs, outputs, and sensor termination within a control rack. According to available references, it is an I/O module with metal oxide varistors and relays, and features multiple terminal blocks (e.g., TB1 and TB2) for field wiring organization — a design choice that improves both installation clarity and long-term serviceability.

A practical engineer will appreciate several field-oriented design elements:

- Rugged Connectivity: Terminal blocks and industrial relay contacts manage field wiring from sensors, switches, or auxiliary devices. These connections are designed to resist vibration and thermal cycling common in turbine halls or compressor enclosures.

- Noise Immunity: Modules in this family often include suppression components (e.g., varistors) to help protect sensitive electronics against transient spikes, inductive load switching, and electrical noise — issues typical in heavy industrial control panels.

- Standard Backplane Integration: In Mark VIe cabinets, interface modules must align with defined electrical and mechanical backplanes. The IS230TVBAH2A adheres to these conventions, which simplifies replacement and reduces integration errors.

- Environmental Resilience: Industrial I/O boards in the Mark VIe ecosystem are built to withstand elevated cabinet temperatures and vibration. Although exact thermal ratings for this model are not documented online, it is engineered alongside other Mark VIe modules that routinely operate in hostile conditions without performance degradation.

Field engineers often note that the most overlooked contributors to system faults aren’t always the high-end processors or communication modules — it’s the interface boards and terminal modules where wiring ends and system logic begins. A poorly managed I/O connection can introduce signal integrity issues, intermittent trips, or false alarms. IS230TVBAH2A mitigates these risks by offering a purpose-built form factor and connection topology that aligns precisely with GE control system expectations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626