Description

In turbine control rooms pulsing with the hum of gas turbines under full throttle, stable signal processing keeps governors, fuel systems, and protective relays in perfect sync to avert overspeeds or flameouts. Maintenance crews reach for the GE DS3800NRFA1D1C during outages on GE Mark IV platforms, slotting it into racks where it relays refined analog inputs from thermocouples, pressure transducers, and vibration pickups straight to the core processor. This ensures operators track exhaust temps, compressor surges, or bearing wear in real time, enabling proactive adjustments that stretch run hours and dodge emergency scrams in power plants from Texas grids to Middle East deserts.

The GE DS3800NRFA1D1C proves indispensable in combined-cycle setups or industrial cogeneration, where it conditions noisy field signals for the <C> or <D> controllers, filtering EMI from nearby generators while preserving accuracy for closed-loop controls. Retrofit specialists favor it for swapping drifted originals in 20-year-old Speedtronics without rewiring the entire island, keeping startups smooth and emissions compliant. In harsh bays with steam leaks or oil mist, its role in channeling data to sequence logic directly bolsters availability, turning raw plant physics into actionable commands for valves, igniters, and breakers.

Product Introduction & Positioning

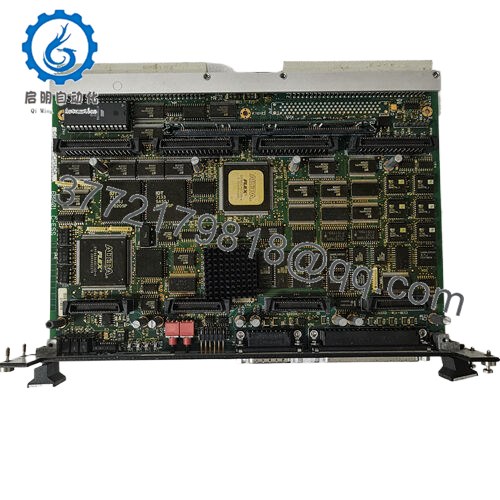

The GE DS3800NRFA1D1C functions as an analog signal conditioning and relay board in GE’s DS3800 series, optimized for Mark IV turbine oversight where it amplifies, linearizes, and distributes process variables across the backplane. Nestled amid power supplies and excitation cards, it grabs multipoint inputs—think RTDs for bearings or 4-20mA loops for fuels—and feeds them to supervisory modules with galvanic isolation to block ground loops. This positions it as the sensory backbone, translating turbine health into digital decisions for sequencing and protection.

Engineers slot the GE DS3800NRFA1D1C into standard cages, leveraging its jumper-configurable gains and filters to match diverse sensors without external boxes. Its value hits home in multisite fleets, where standardized pinouts cut training and spares logistics. Beyond basic acquisition, built-in multiplexing cuts cable runs, easing panel density in upgrade-constrained sites.

For integrators eyeing DCS tie-ins, the GE DS3800NRFA1D1C bridges legacy racks to modern historians via status discretes, supporting predictive analytics on trend data without full rip-and-replace.

Key Technical Features & Functional Benefits

The GE DS3800NRFA1D1C excels at high-fidelity signal capture, boasting 12-16 bit resolution on channels that handle Type K/J thermocouples or strain gauges, with cold-junction compensation holding errors under 1°C across turbine transients. Overrange clamps and burnout detection flag bad sensors instantly, routing failsafes to the host without data gaps.

Toughened for enclosure extremes, the GE DS3800NRFA1D1C sports potted relays and mil-grade op-amps surviving 70°C spikes, 95% humidity, and 10g vibes, with front DIP switches for zero/span tweaks visible under lexan covers. Low drift keeps calibrations valid years between outages.

Backplane handshaking with the GE DS3800NRFA1D1C delivers polled or interrupt-driven updates, syncing with <R> core cycles for sub-second latency in alarm loops. Jumper banks tailor impedance and excitation, mating seamlessly to Mark IV I/O trees or third-party drives.

Endurance stems from redundant paths and self-test modes, logging faults to EEPROM for post-trip forensics, targeting MTBF beyond turbine majors.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE DS3800NRFA1D1C |

| Brand | General Electric (GE) |

| Type | Analog input relay/conditioning board |

| Input Types | Thermocouple, RTD, 4-20mA, voltage |

| Power Supply | +5V/±15V from backplane |

| Operating Temperature | -20 to 70 degrees Celsius |

| Mounting | Mark IV card rack |

| Dimensions | Standard DS3800, approx. 260 x 130 x 50 mm |

| Weight | Approximately 0.6 kg |

| Channels | 16-32 multiplexed inputs |

| Interfaces | Backplane bus, field terminals |

| Certifications | Power gen/industrial standards |

| Cooling | Natural convection |

| Environmental Rating | Coated for dusty/humid turbine environments |

| Resolution | 12-16 bits typical |

| Calibration | Jumper/DIP adjustable |

- DS3800NRFA1D1C

Related Modules or Compatible Units

GE DS3800NPSE1C1B – Power supply feeding clean rails to the GE DS3800NRFA1D1C for stable analog processing.

GE DS3800NMEA1HEF – Excitation board sharing backplane data from GE DS3800NRFA1D1C inputs in genset controls.

GE DS3800NRCA1D1C – Sister input card with expanded jumpers complementing the GE DS3800NRFA1D1C in dense racks.

GE DS3800HMPA – Protection module acting on GE DS3800NRFA1D1C signals for trip logic.

GE IS200NRFA – EX2100 analog successor upgrading from GE DS3800NRFA1D1C setups.

GE DS3800NDCI – Digital companion buffering GE DS3800NRFA1D1C outputs to field devices.

GE DS3800NFCF1D1C – Firing circuit tying into GE DS3800NRFA1D1C feedback loops.

Installation Notes & Maintenance Best Practices

Position the GE DS3800NRFA1D1C away from power stabs in the rack, torquing terminals to spec and verifying shield drains to chassis—stray EMI corrupts T/C baselines fast. Pre-power, jumper channels per sensor maps and loopcheck with a decade box, confirming linearity before rack-in. Filler panels seal gaps, channeling rack airflow over heatsinks.

Monthly scans spot relay chatter or drift via test points; annually, bake out moisture and rezero against master sensors during cold irons. Cycle self-tests quarterly, archiving logs—refurbs shine here, but match revisions to avoid bus clashes.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626