Description

In distributed industrial automation systems, engineers often face the challenge of placing I/O racks far from the main controller while avoiding the high costs, noise susceptibility, and inflexibility of long parallel cable runs. Traditional local I/O limits expansion options, complicates maintenance in hazardous or space-constrained areas, and makes scaling for growing processes expensive and time-consuming.

The GE IC695NIU001-AB resolves this by transforming a standard RX3i universal backplane into a fully independent remote I/O station on an Ethernet network. As an Ethernet Network Interface Unit, it scans and manages both RX3i and legacy Series 90-30 I/O modules locally, then exchanges data automatically with one or more master controllers using Ethernet Global Data (EGD). This delivers deterministic, high-speed I/O updates over standard industrial Ethernet cabling, supporting distances up to 100 meters per segment without repeaters.

The GE IC695NIU001-AB becomes critical in scenarios like extending monitoring points across large manufacturing floors, adding remote drops in water treatment plants, or building modular control in packaging and material handling lines. It provides high reliability for I/O signals in process control environments requiring continuous operation, easy expansion, and reduced wiring in industrial automation applications where signal integrity and system uptime are non-negotiable.

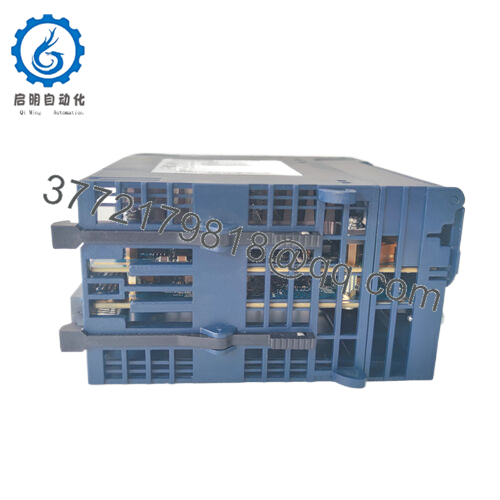

The GE IC695NIU001-AB mounts in the CPU slot of an RX3i universal backplane and handles complete local I/O scanning across the main rack and optional Series 90-30 expansion racks. Ethernet connectivity requires at least one IC695ETM001 module installed in the same backplane—the NIU routes all network traffic through these 10/100 Mbps interfaces.

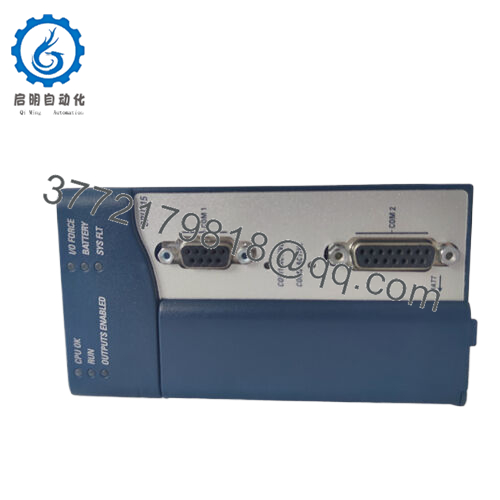

Data exchange relies on EGD producer/consumer relationships configured in Proficy Machine Edition: the master (typically an RX3i CPU) defines exchanges mapping %I, %Q, %AI, %AQ, and status references. Once established, transfers occur automatically without polling logic, achieving update rates suitable for most real-time loops. The NIU includes two serial ports (RS-232 and RS-485) for local diagnostics, Station Manager access, or Modbus RTU integration.

Diagnostics are robust—front-panel LEDs show module status, I/O scanning, faults, and serial activity—while embedded status data reports health to the master. In the automation stack, the GE IC695NIU001-AB acts as a remote I/O adapter, allowing layered architectures where masters handle complex logic and multiple NIUs distribute field signals efficiently.

| Specification | Details |

|---|---|

| Model Number | IC695NIU001-AB |

| Brand | GE (Emerson) |

| Type | Ethernet Network Interface Unit (NIU) |

| Input Voltage | Backplane: 3.3 VDC (1.25 A nom.), 5 VDC (1.0 A nom.) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i universal backplane (CPU slot) |

| Dimensions | Approx. 145 mm x 140 mm x 40 mm (H x D x W) |

| Weight | Approx. 0.45 kg |

| Interface/Bus | RX3i PCI/serial backplane; Requires IC695ETM001 for Ethernet; RS-232/RS-485 serial |

| Compliance | UL, cUL, CE, RoHS |

| Supported Protocols | Ethernet Global Data (EGD); SRTP; Modbus RTU (serial) |

| Typical Power Draw | 6.25 W (combined 3.3V and 5V backplane) |

- IC695NIU001-AB

Selecting the GE IC695NIU001-AB ensures exceptional I/O signal reliability through proven EGD exchanges, even across busy plant networks, minimizing latency or dropped updates that could disrupt production. Engineered for sustained industrial use, it maintains consistent scanning and data integrity in electrically noisy or extended-distance setups, providing long-term performance where traditional wiring would degrade over time.

Maintenance efficiency stands out with clear LED diagnostics and automatic status reporting, allowing quick identification of network or module issues without extensive testing. Integration overhead is low within the RX3i family—standard Proficy tools handle configuration, and no custom drivers are needed beyond EGD setup.

The overall value appears in reduced total cost of ownership: shorter cable runs lower installation expenses, while modular remote drops simplify future expansions. The GE IC695NIU001-AB delivers dependable operation across years of unattended service in demanding control panels.

The GE IC695NIU001-AB is frequently deployed in automotive manufacturing for remote monitoring of assembly line conveyors and weld cells, where distributed I/O supports fast data cycles and harsh conditions from vibration or EMI.

Water and wastewater facilities use it in process control environments spanning remote pump houses and treatment skids, ensuring high reliability for level, flow, and valve signals over extended networks.

Power plants incorporate it for auxiliary systems like fuel handling or cooling tower controls, maintaining critical system uptime in noisy electrical settings while allowing isolated drops for safer maintenance. In food processing, pharmaceuticals, and metals industries, the GE IC695NIU001-AB excels where modular integration and deterministic updates are essential.

IC695NIU001-AA – Initial release with core EGD functionality

IC695NIU001-AC – Updated firmware for enhanced diagnostics

IC695NIU001-BE – Later revision supporting up to eight ETM modules

IC695NIU001-CK – Current production revision with latest improvements

IC695ETM001 – Required Ethernet Transmitter Module (10/100 Mbps) for network connectivity

IC695CHS012 – 12-slot RX3i universal backplane for main rack

IC693CHS398 – Series 90-30 expansion backplane for additional I/O density

IC695PNC001 – PROFINET controller alternative for modern network upgrades

Before installing the GE IC695NIU001-AB, ensure your RX3i universal backplane and power supply can handle the combined load—include at least one IC695ETM001 and verify total current draw. Confirm network planning with unique IP assignments for each ETM and alignment with the master’s subnet.

Leave space for airflow and proper cable routing, especially for serial ports if used for Station Manager. Prepare a Proficy project with exchange definitions tested offline to catch mapping errors early.

For ongoing maintenance, routinely check front-panel LEDs during inspections for link or fault indications, and monitor status references in the master logic for trends. Inspect connectors periodically in dusty or humid areas, and perform a yearly exchange validation by temporarily forcing outputs. Stock a pre-configured spare (NIU + ETM) with your standard settings—this enables fast swaps and minimizes impact on running processes.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626