Description

In turbine control systems for gas and steam applications, precise actuation of fuel, steam, or inlet guide valves is fundamental to maintaining stable operation, efficient load response, and protection against overspeed or positioning errors. Challenges arise when integrating electro-hydraulic servo valves into distributed architectures—issues like coil current mismatch, position feedback drift, electrical noise on long runs, or limited cabinet space can lead to inaccurate valve positioning, delayed responses, or unnecessary trips that impact availability and efficiency. In simplex configurations or space-constrained retrofits, a compact, noise-immune terminal board becomes critical for reliable signal conditioning and diagnostics in high-vibration, high-temperature environments.

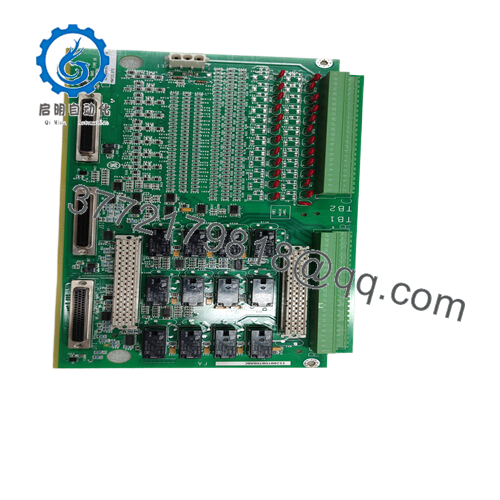

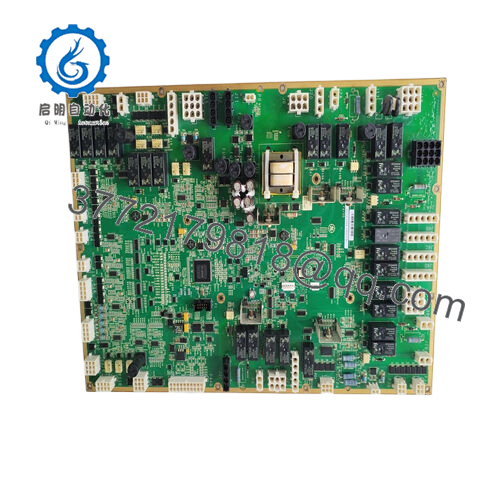

The GE IS200DSVOH2BDB addresses these needs as a simplex DIN-rail mounted servo terminal board in the Speedtronic Mark VI turbine control series, offering high-reliability interfacing for industrial automation and process control. It supports multiple servo channels with selectable coil currents, LVDT/LVDR position feedback, and pulse rate inputs for flow measurement, while providing robust isolation in demanding turbine skids. This board is particularly essential in situations requiring deterministic servo performance—such as precise fuel metering during load changes, steam valve regulation in combined-cycle plants, or IGV control for compressor stability—where signal integrity directly influences turbine efficiency and emissions compliance. By facilitating clear diagnostics and simplified wiring, the GE IS200DSVOH2BDB enhances overall system stability in process control environments, especially when upgrading legacy setups or optimizing for minimal footprint.

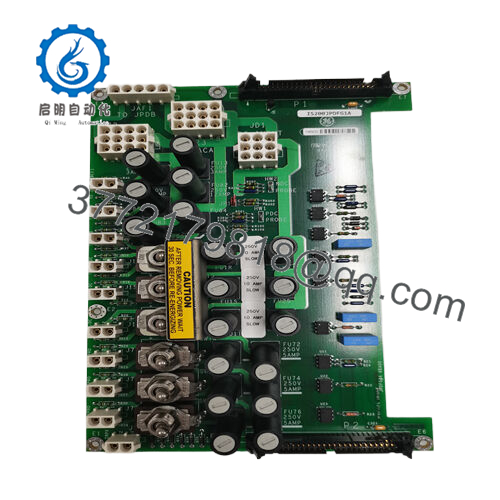

The GE IS200DSVOH2BDB functions in the I/O termination layer of the Mark VI architecture, typically mounted on DIN-rail in auxiliary panels or directly in control cabinets. It connects to the VSVO servo processor board via cable, handling up to two servo outputs with jumper-selectable coil currents (10-120 mA ranges), excitation for up to six LVDT position sensors, and active pulse rate inputs for flow transducers. Positioned between field devices and the VME processor rack, it conditions signals for low-latency feedback loops essential in regulator control.

The board includes barrier terminals for field wiring and Sub-D connectors matching larger TSVO boards, allowing straightforward migration or parallel operation. Diagnostics are relayed back to the toolbox software, reporting issues like open circuits, feedback mismatches, or excitation faults without requiring external test equipment. While designed for simplex applications, it integrates seamlessly into broader Mark VI networks via IONet, supporting deterministic updates for valve positioning. The GE IS200DSVOH2BDB prioritizes compact stacking on rails, making it ideal for distributed setups where multiple servo channels must coexist with vibration or proximity sensors.

- IS200DSVOH2BDB

| Specification | Details |

|---|---|

| Model Number | IS200DSVOH2BDB |

| Brand | GE (Speedtronic Mark VI) |

| Type | Simplex DIN-Rail Mounted Servo Terminal Board |

| Input Voltage | 28V DC (typical from PSVO) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | DIN-rail (stackable) |

| Dimensions | Compact (approx. 200 x 150 x 50 mm) |

| Weight | Approx. 1 kg |

| Interface/Bus | Cable to VSVO (37-pin typical) |

| Compliance | CE, UL, Class 1 Div 2 (H2 revision) |

| Supported Protocols | Mark VI internal I/O signaling |

| Typical Power Draw | Low (board-level, <20W) |

Choosing the GE IS200DSVOH2BDB delivers a terminal board engineered for enduring reliability in servo loops, where consistent current drive and feedback accuracy ensure long-term performance amid thermal cycles and mechanical stress. Its DIN-rail design and certification upgrades support sustained operation in hazardous locations, reducing risks of environmental-related failures.

Integration advantages are clear in retrofits—compatible connectors and jumper configurations minimize engineering overhead, enabling quick adaptation to existing valve actuators without major rewiring. In service, the value appears through maintenance efficiency: onboard filtering and diagnostic passthrough allow rapid isolation of field issues, while the compact form factor optimizes cabinet utilization.

At its core, the GE IS200DSVOH2BDB strengthens turbine process control by providing a dependable, space-efficient interface that maintains precise actuation, contributing to higher availability and reduced operational costs.

The GE IS200DSVOH2BDB is widely deployed in power generation settings with heavy-duty gas or steam turbines, where servo-controlled valves must respond rapidly to load demands or transients in harsh conditions involving dust, humidity, and vibration. In combined-cycle or simple-cycle plants, it handles fuel and steam valve interfacing for continuous uptime during peak operation.

Compressor stations in oil and gas or industrial drive applications use it for IGV and bleed valve control, supporting fast data cycles while tolerating electrical noise from adjacent motors. These process control environments benefit from its simplex reliability and diagnostic support for critical system uptime.

IS200DSVOH1AAA – Earlier simplex DIN-rail variant without Div 2 certification

IS200TSVOH1B – Larger barrier-type servo terminal board for higher channel density

IS200VSVOH1B – Companion servo processor board (VSVO) for control logic

IS200TBCIH2CAA – Contact input terminal board often paired for trip interlocks

IS200TVIBH2B – Vibration termination board for proximity sensor integration

IS200TRLYH1B – Relay output terminal board for solenoid commands

IS200VAICH1D – Analog input board for additional feedback channels

IS200DSPXH1D – Digital signal processor complement for advanced regulation

Before installing the GE IS200DSVOH2BDB, verify DIN-rail compatibility and cabinet space for vertical stacking—ensure secure mechanical fixation to withstand vibration. Check jumper settings for coil current matching your servo valves and confirm cable type (typically 37-pin) aligns with the VSVO board revision to prevent signal mismatches. Validate power from the distribution board for clean 28V DC without excessive noise.

Maintenance is generally low-effort: routinely inspect barrier terminals for tightness and signs of corrosion, especially in humid turbine bays. Monitor toolbox diagnostics for any persistent feedback errors, and clean dust from the board surface during outages. A periodic functional check—stroking valves via the control sequence—verifies position accuracy and excitation health without specialized tools.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626